Gw Carbide - CBN Grinding Wheel Diamond Grinding Wheel

Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd.- Material:Silicon Carbide

- Abrasive:Normal Abrasive

- Shapes:Edge Shape

- Types:Cutting Wheel

- Working Style:Cutting

- The Ranges:Diamond & CBN Wheels, Diamond & CBN Cutting Blades

Base Info

- Working Fields:Tools, Molds, Bearing, Compressor,

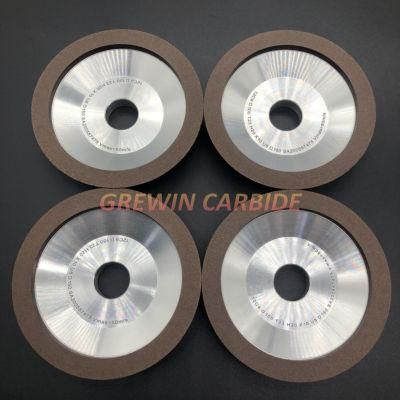

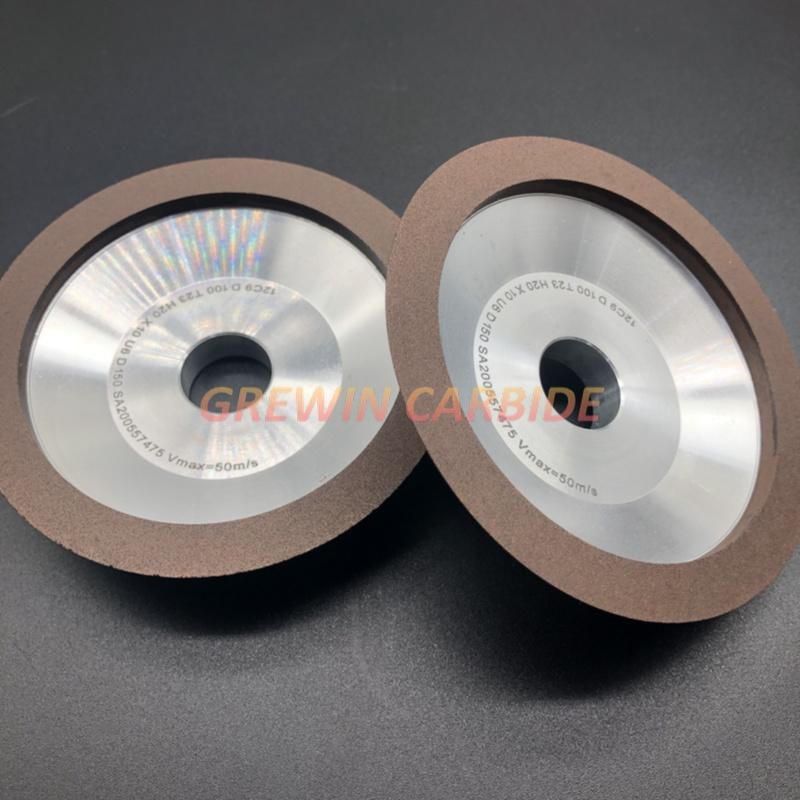

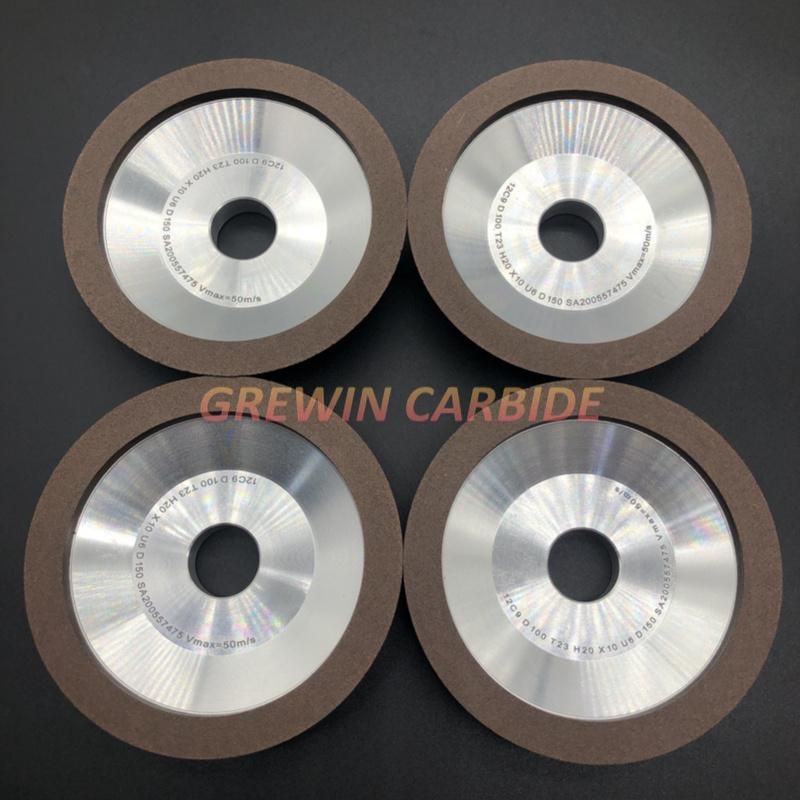

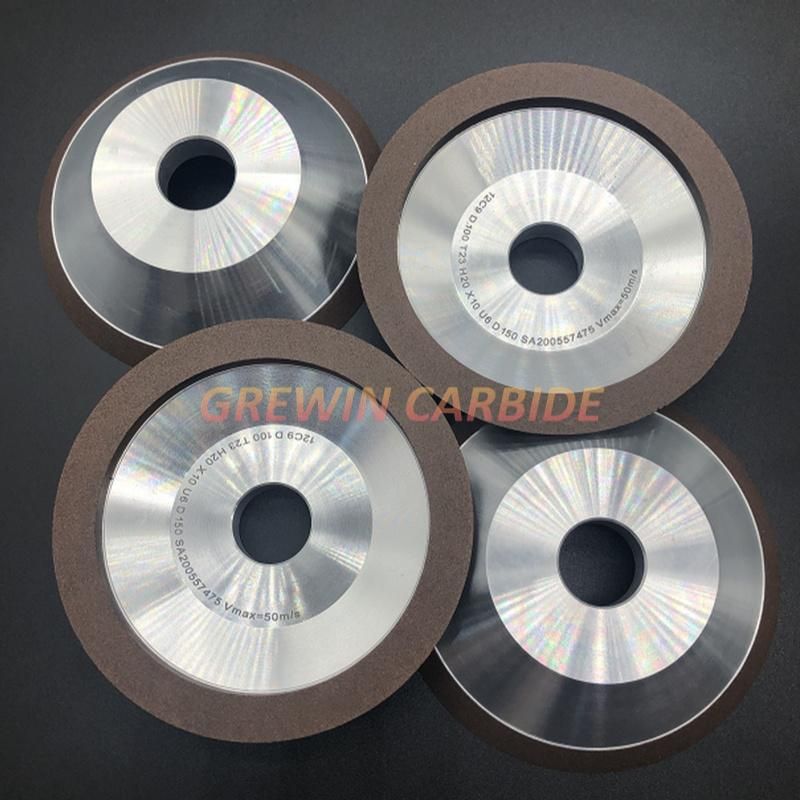

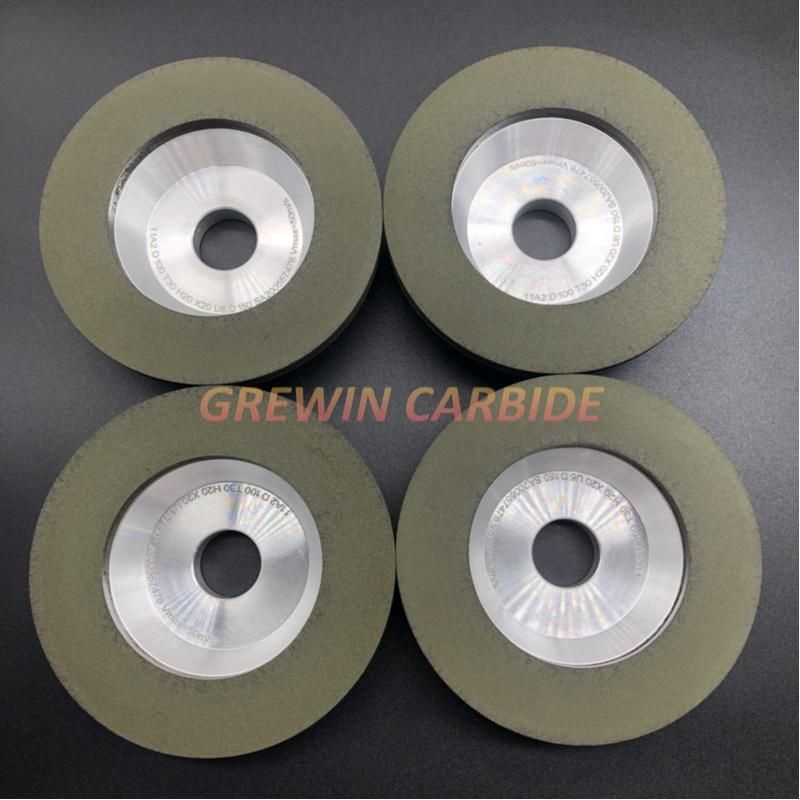

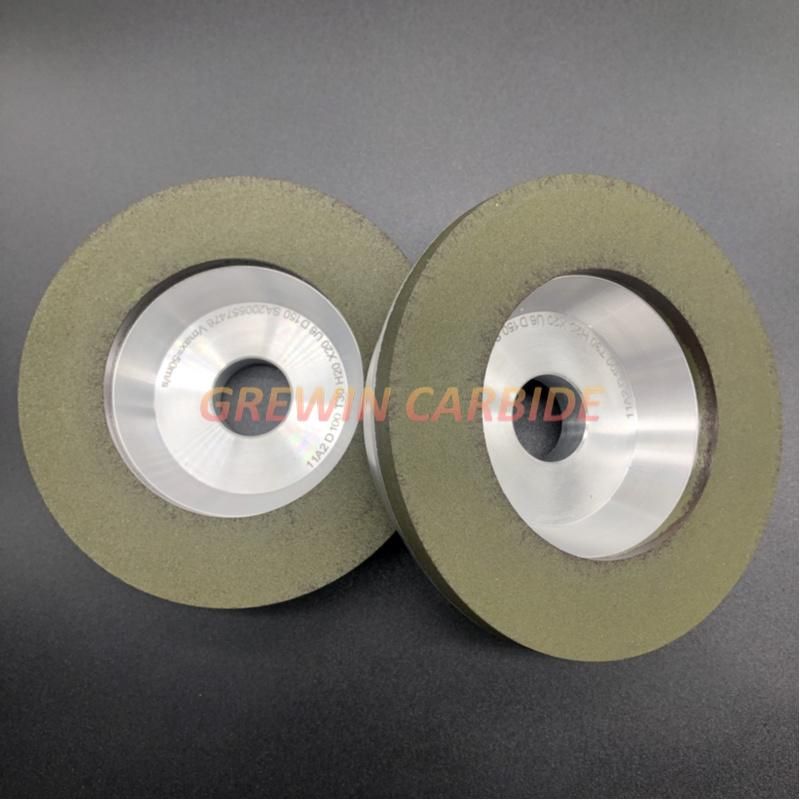

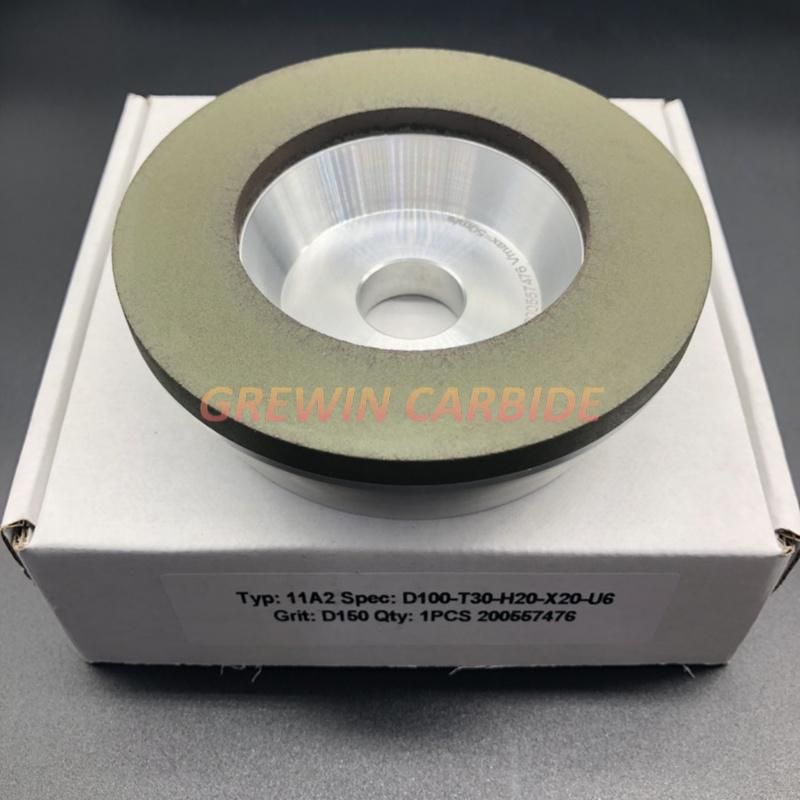

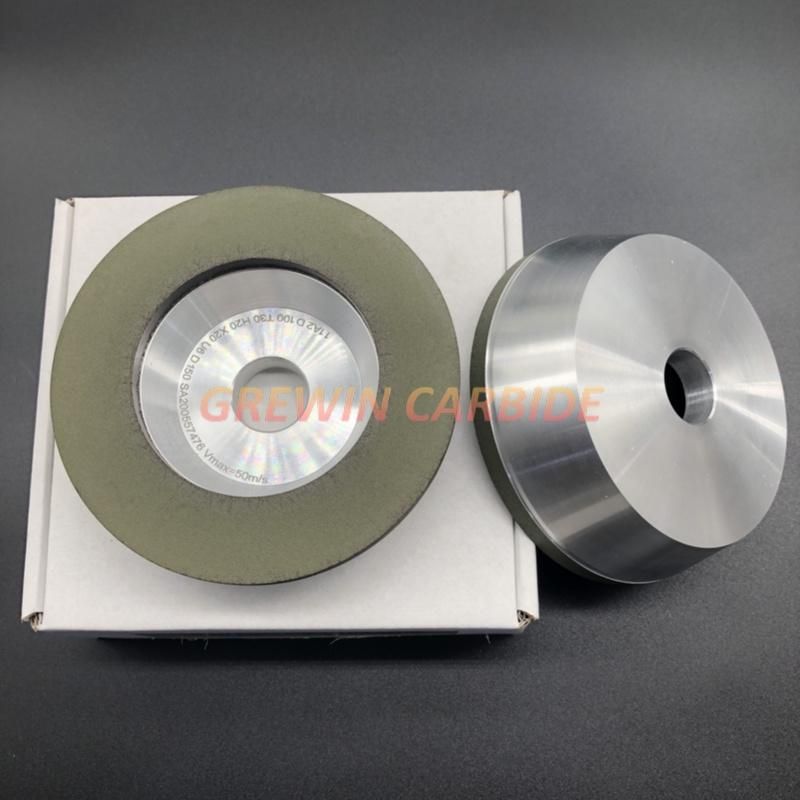

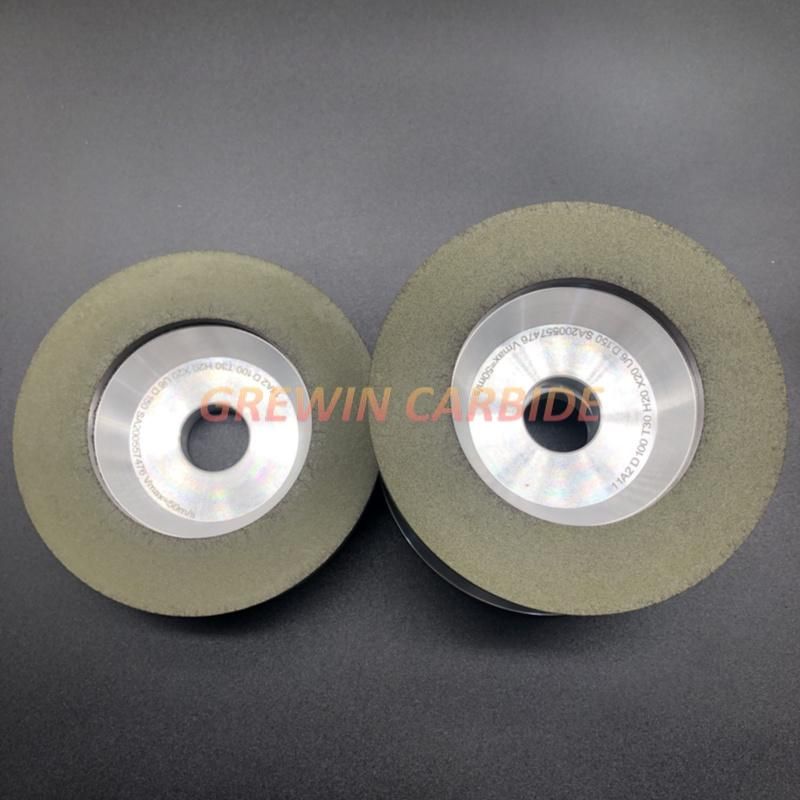

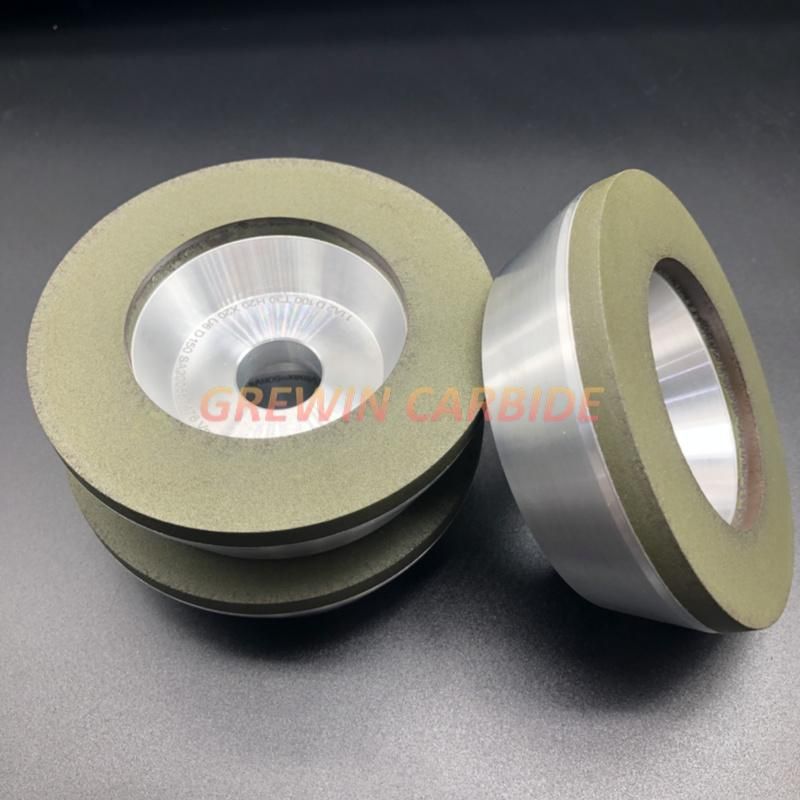

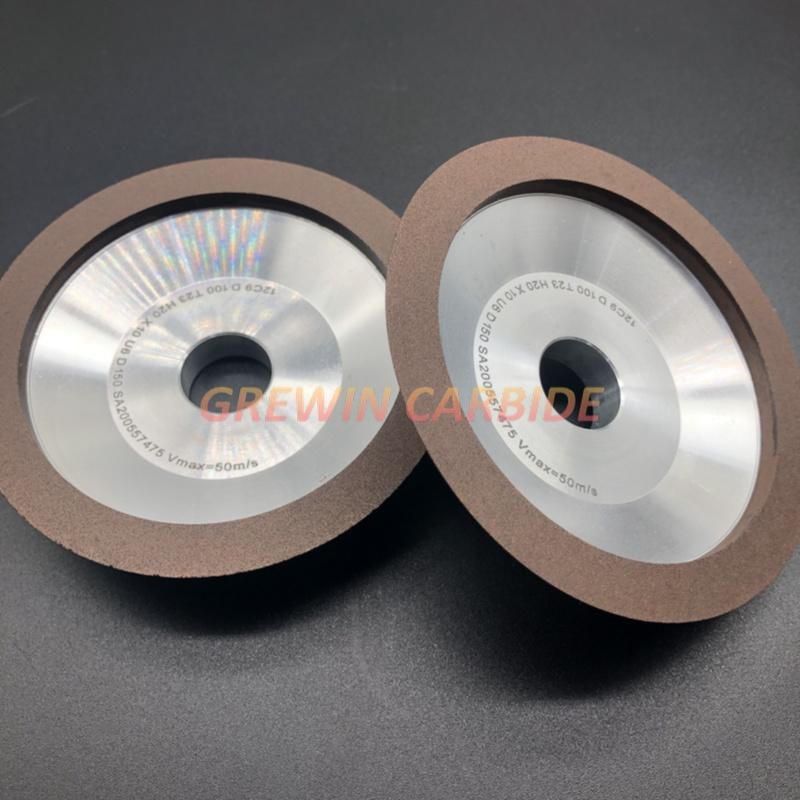

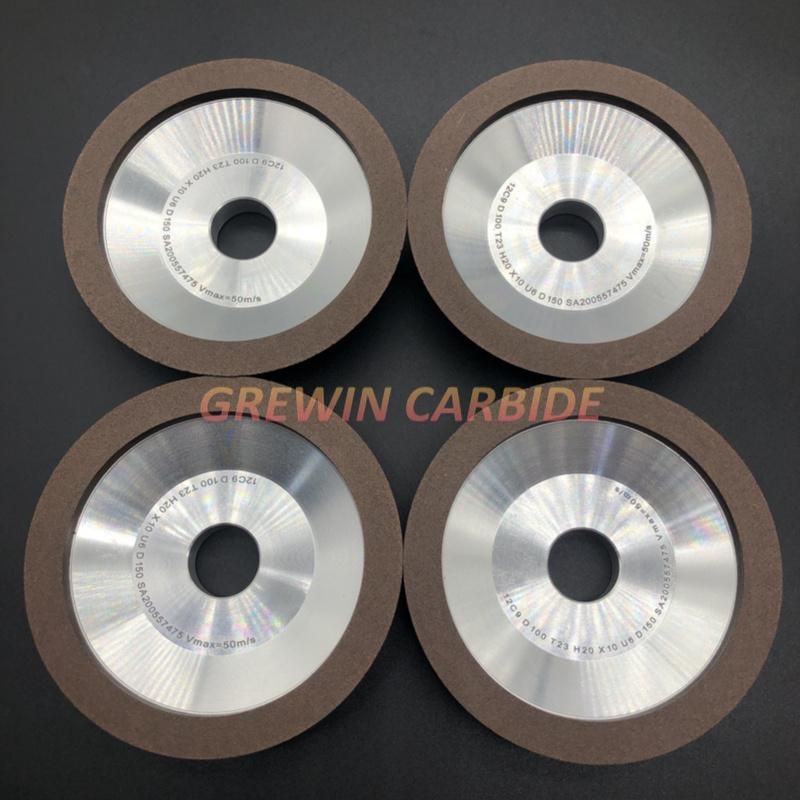

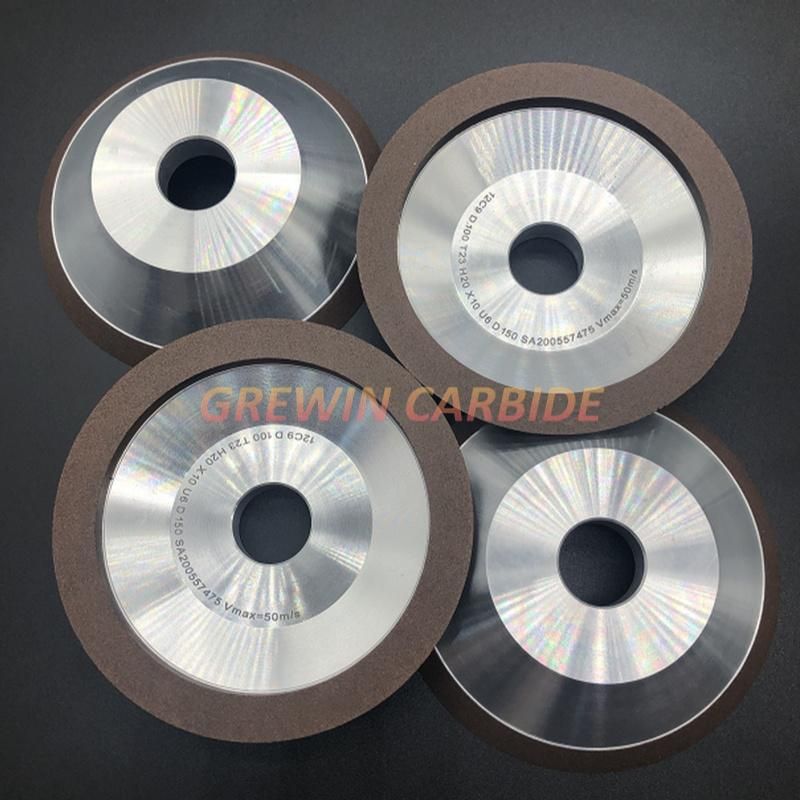

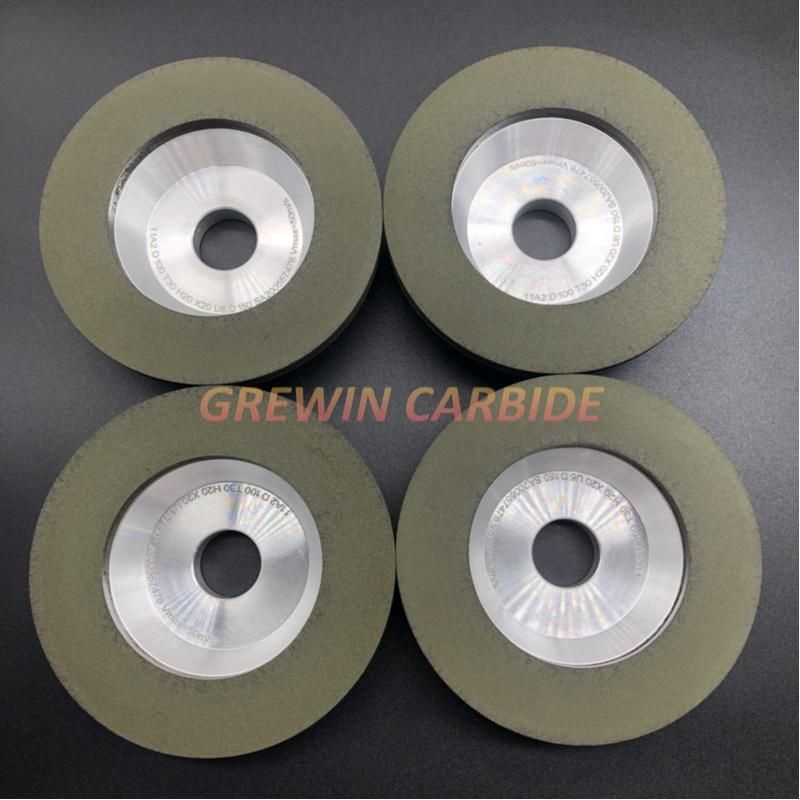

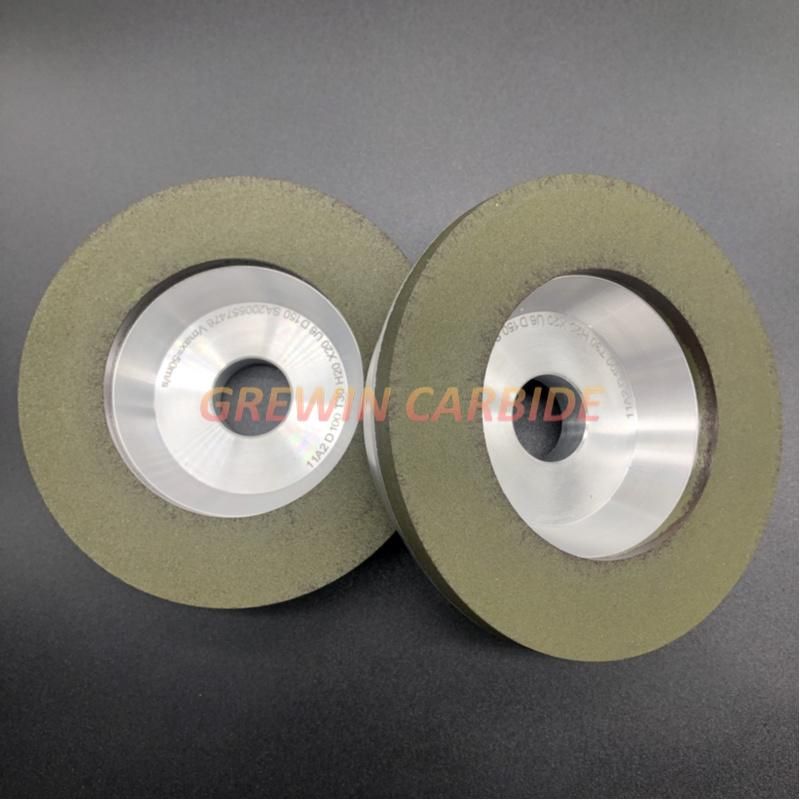

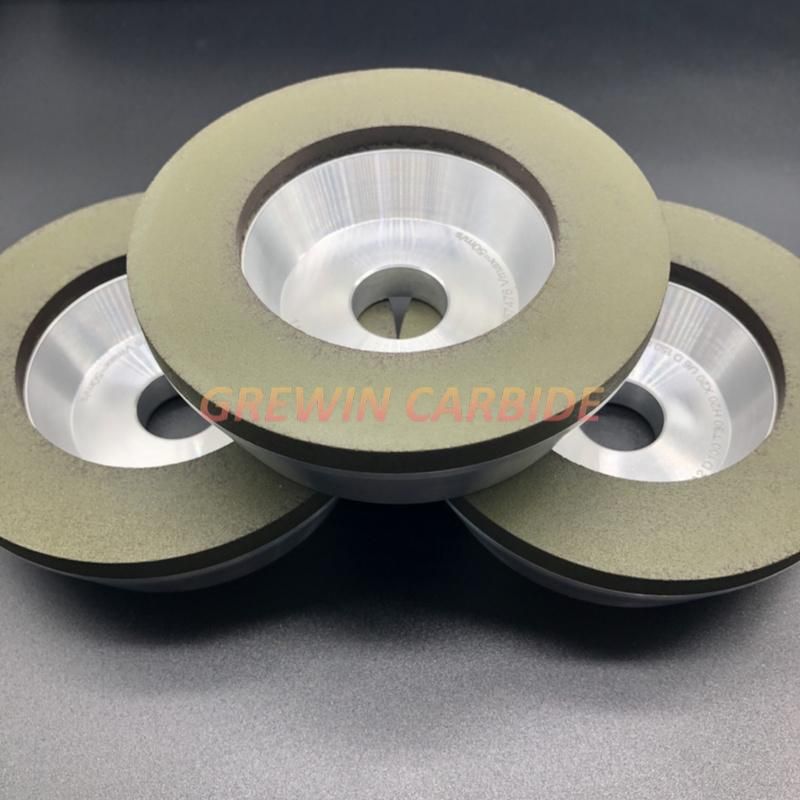

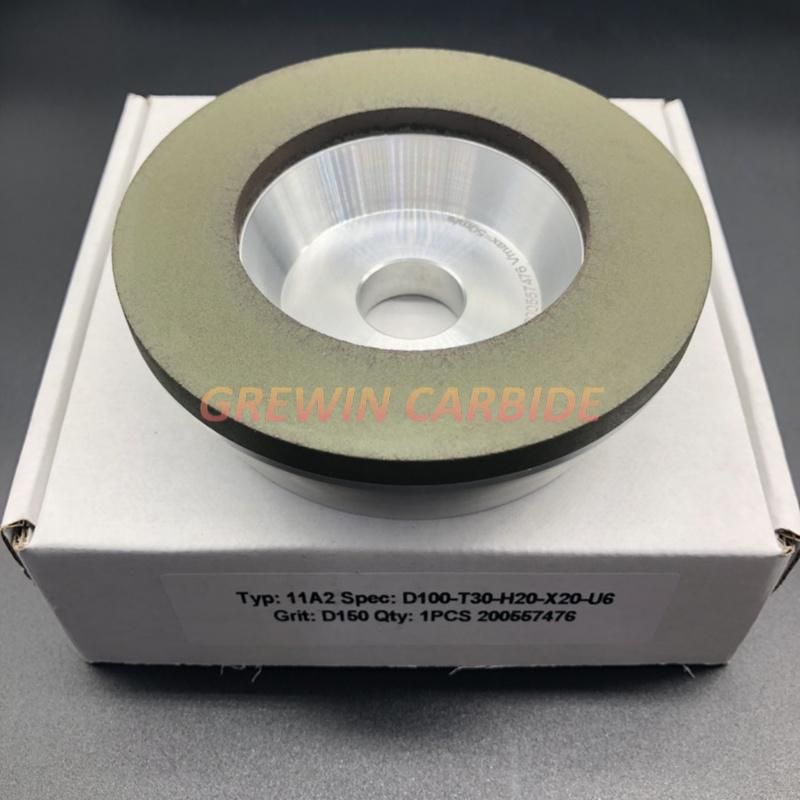

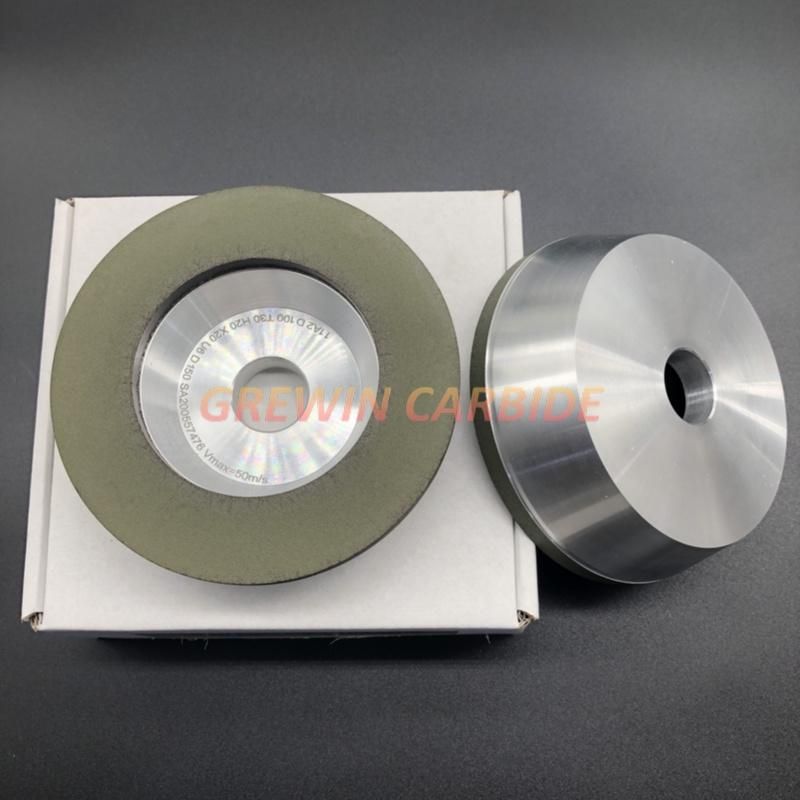

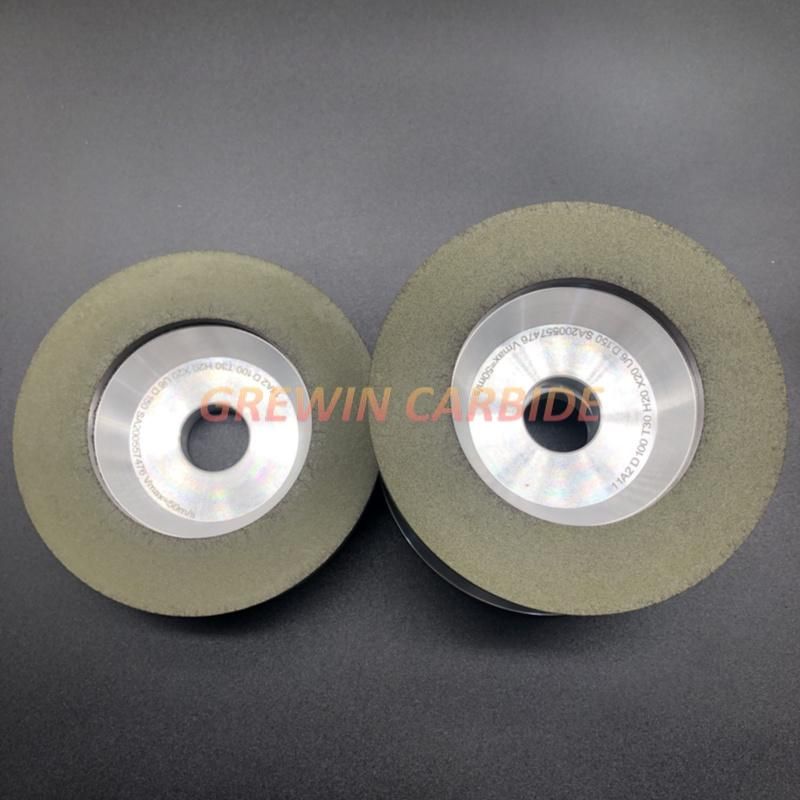

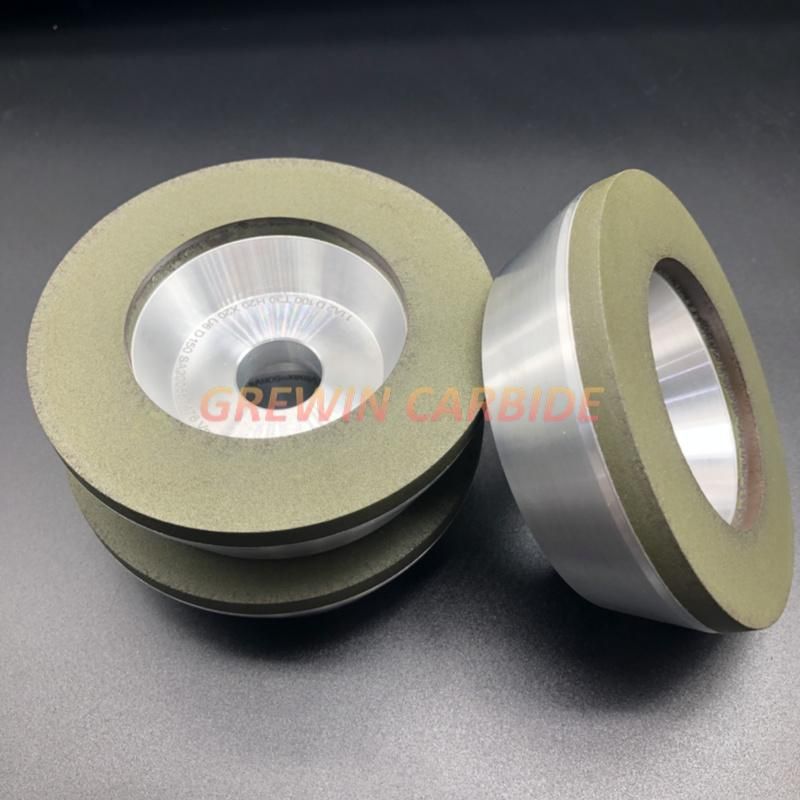

- Type:1A1, 1V1, 1A1r, 4A2, 6A2, 9A3, 11V9, 12V9, 14A1

- Bond:Resin,Vitrified,Metal, Electroformed Bond

- Concentration:50,75,100,125, etc..

- General Coarse Grinding:Grit 80,100---120,140

- Semi Finish Grinding:Grit 140,170---230,270

- Fine Grinding:Grit 270,325---325,400

- Polishing:Grit W40 to Fine Powder

- Delivery Time:15-20 Days

- Transport Package:Plastic Box, Standard Export Carton

- Specification:1A1

- Trademark:GW or OEM

- Origin:Zhuzhou, Hunan

- HS Code:6804210000

- Production Capacity:50000 PCS,Month

Description

Range of roughness (Ra) Unit:μmGrain size Resin bond (B) Metal bond (M) 80/100 ~100/120 --- 3.2---1.6 100/120~170/200 0.8---0.4 1.6---0.8 170/200~230/270 0.4---0.2 0.8---0.4 325/400~M12/22 0.2---0.1 M10/20~M3/6 0.1---0.05 M3/6~M0/1 0.05---0.025

3- Conventional Grinding Wheel Variety

☆ Shape code: 1A1 1.Parallel grinding wheel: suitable for all types of cylinder grinding, surface and end face grinding. 2.Centerless grinding wheel: suitable for processing the outer circle of bar and thread. Divided into rough grinding, precision grinding and polishing.

☆ Shape code: 2A2 1.Cup & ring type grinding wheel: applicable to the processing of various materials of the end surface grinding, can be processed two end face at the same time.

☆ Shape code: 12C2 1.Abrasive disc: It is suitable for various materials' grinding and chamfer.

☆ Shape code: 6A2 1.Cup-shaped grinding wheel: Suitable for all types of surface and end grinding.

☆ Shape code: 4B1, 1V1 1.Single bevel wheel: suitable for precision grinding and notching.

☆ Shape code: 1F1, 1FF6 1.Arc grinding wheel: suitable for various types of molding grinding.

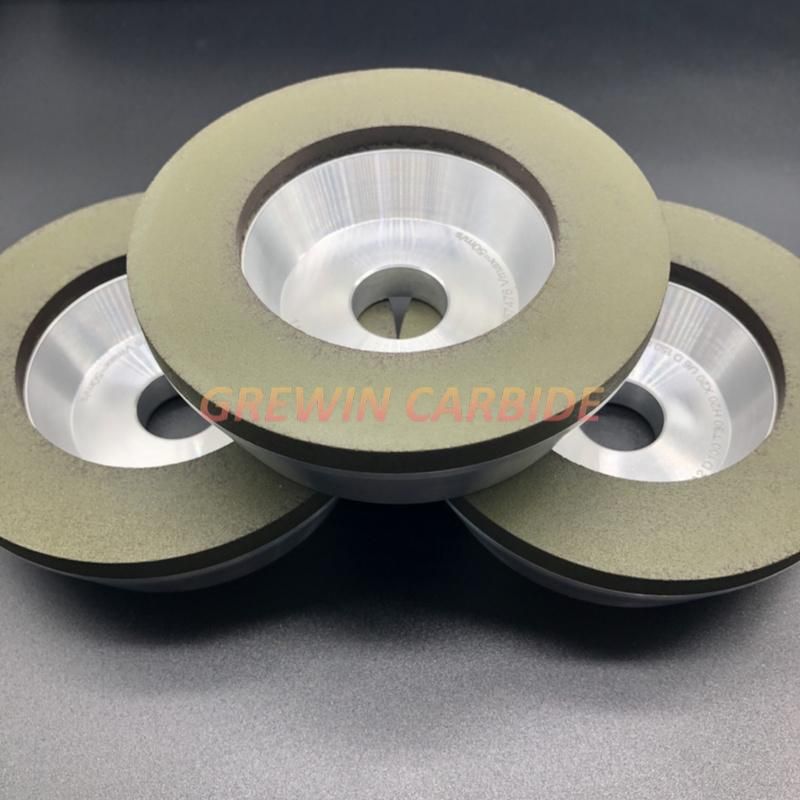

☆ Shape code: 11V9 1.Bowl-shaped grinding wheel: Suitable for end, flat and edge grinding of cutter.

☆ Shape code: 12A2, 12V9, 12V2 1.Dish-shaped grinding wheel: Suitable for the cutting tool's end face, surface and the cutter edge grinding.

4- Application

Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels are the ideal tool for grinding hard and brittle materials such as glass, ceramics, precious stones, stone, and hard alloys. With the progress of the times, the development of science, the needs of society, the development of new materials, the grinding process is developing in the direction of high quality, high precision, high efficiency and automation. The role of diamond grinding wheel is becoming more and more obvious. Metal bond agent The diamond grinding wheel has high holding strength, long service life and low wear, which makes the diamond grinding wheel fully exert its strong wear-resisting cutting ability in high-speed and ultra-high-speed high-efficiency and high-precision grinding processing, especially in hard and brittle processing. The material has obvious advantages and is widely used. Diamond grinding wheels are used in almost every industry sector, including aerospace, mold manufacturing, semiconductor manufacturing, and optical processing. At present, ceramic materials, optical materials, aero-engine turbine blades, silicon wafer products, etc. are mostly ground with diamond wheels.

5- How to buy our grinding wheel According to Customers their own processing products and the requirements of the different machines, choose different shape of grinding wheel; According to the requirements of the processing efficiency, choose different bonded grinding wheel; And according to the different roughness requirements, choose a different abrasive particle size.

While ordering the grinding wheel, please tell us the grinding wheel drawings, processing materials, processing accuracy requirements, processing roughness requirements, as well as the use of grinding wheel so that we can design and manufacture more suitable for your need of our grinding wheel products.

More details

We are waiting for your inquiry!

3- Conventional Grinding Wheel Variety

☆ Shape code: 1A1 1.Parallel grinding wheel: suitable for all types of cylinder grinding, surface and end face grinding. 2.Centerless grinding wheel: suitable for processing the outer circle of bar and thread. Divided into rough grinding, precision grinding and polishing.

☆ Shape code: 2A2 1.Cup & ring type grinding wheel: applicable to the processing of various materials of the end surface grinding, can be processed two end face at the same time.

☆ Shape code: 12C2 1.Abrasive disc: It is suitable for various materials' grinding and chamfer.

☆ Shape code: 6A2 1.Cup-shaped grinding wheel: Suitable for all types of surface and end grinding.

☆ Shape code: 4B1, 1V1 1.Single bevel wheel: suitable for precision grinding and notching.

☆ Shape code: 1F1, 1FF6 1.Arc grinding wheel: suitable for various types of molding grinding.

☆ Shape code: 11V9 1.Bowl-shaped grinding wheel: Suitable for end, flat and edge grinding of cutter.

☆ Shape code: 12A2, 12V9, 12V2 1.Dish-shaped grinding wheel: Suitable for the cutting tool's end face, surface and the cutter edge grinding.

4- Application

Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels are the ideal tool for grinding hard and brittle materials such as glass, ceramics, precious stones, stone, and hard alloys. With the progress of the times, the development of science, the needs of society, the development of new materials, the grinding process is developing in the direction of high quality, high precision, high efficiency and automation. The role of diamond grinding wheel is becoming more and more obvious. Metal bond agent The diamond grinding wheel has high holding strength, long service life and low wear, which makes the diamond grinding wheel fully exert its strong wear-resisting cutting ability in high-speed and ultra-high-speed high-efficiency and high-precision grinding processing, especially in hard and brittle processing. The material has obvious advantages and is widely used. Diamond grinding wheels are used in almost every industry sector, including aerospace, mold manufacturing, semiconductor manufacturing, and optical processing. At present, ceramic materials, optical materials, aero-engine turbine blades, silicon wafer products, etc. are mostly ground with diamond wheels.

5- How to buy our grinding wheel According to Customers their own processing products and the requirements of the different machines, choose different shape of grinding wheel; According to the requirements of the processing efficiency, choose different bonded grinding wheel; And according to the different roughness requirements, choose a different abrasive particle size.

While ordering the grinding wheel, please tell us the grinding wheel drawings, processing materials, processing accuracy requirements, processing roughness requirements, as well as the use of grinding wheel so that we can design and manufacture more suitable for your need of our grinding wheel products.

More details

Customization of Diamond Grinding Wheel

If you need to customize, please provide following:

1. Dimensions, include outer diameter, bore diameter, thickness, width and thickness of abrasive layer ;

2. Abrasive, abrasive grit size and concentration ;

3. Bonding agent ;

4. Application of wheel ;

5. Picture and drawing of wheel ;

Then design and quotation can be made for you .

We are waiting for your inquiry!