Wear Resistant Alumina Ceramic Bricks as Wear Liner for Ball Mill

ZIBO QIMINGXING NEW MATERIAL INCORPORATED CO., LTD.- Material:Alumina

- Content:>90%

- Usage:Construction, Machinery, Chemical, Petroleum, Grind, Refractory Material

- Processing Type:Isostatic Pressing Type

- Size:Middle

- Color:White

Base Info

- Model NO.:alumina

- Customized:Customized

- Market:Global

- Alumina Content:92~95%

- Sample Time:1-3 Days

- MOQ:1 Ton

- Transport Package:by Cartons + Pallet.

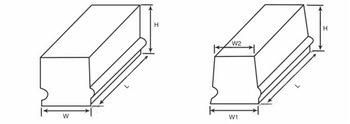

- Specification:150*50*H40~H120

- Trademark:qimingxing

- Origin:Shandong

- HS Code:69091200

- Production Capacity:18000

Description

Basic Info.

Model NO. alumina Customized Customized Market Global Alumina Content 92~95% Sample Time 1-3 Days MOQ 1 Ton Transport Package by Cartons + Pallet. Specification 150*50*H40~H120 Trademark qimingxing Origin Shandong HS Code 69091200 Production Capacity 18000Product Description

Wear resistant alumina ceramic bricks as wear liner for ball mill1.Advantages

~ Alumina mill linings (alumina bricks and tiles) are the perfect solution for protecting grinding ball mills from wear, as they allow for a constant use over an extended period of time without any routine maintenance.

~ High strength, high density, high abrasion, entire specification, strong practicability.

~ It can be used for ball mill, mixing mill, vibration mill, sand mill, etc.

2.Application: Widely used in ball mill and pipeline as wear-resistance lining. The main function is to effectively resist the impact of material on the pipe wall, which can effectively prolong the service life of the equipment

Chemical Composition & Technical Parameter

| Item | 92 | 95 |

| Al2O3 (%) | >92 | >95 |

| Bulk Density(g/cm3) | >3.60 | >3.65 |

| Hardness (Mohs) | 9 | 9 |

| Wear Loss (%) | <0.01 | <0.01 |

| Color | White | White |

3.Size for choose: H40~H120mm ( rectangle brick / Half rectangle brick/Trapezoid brick /Half Trapezoid brick/ Flake brick)

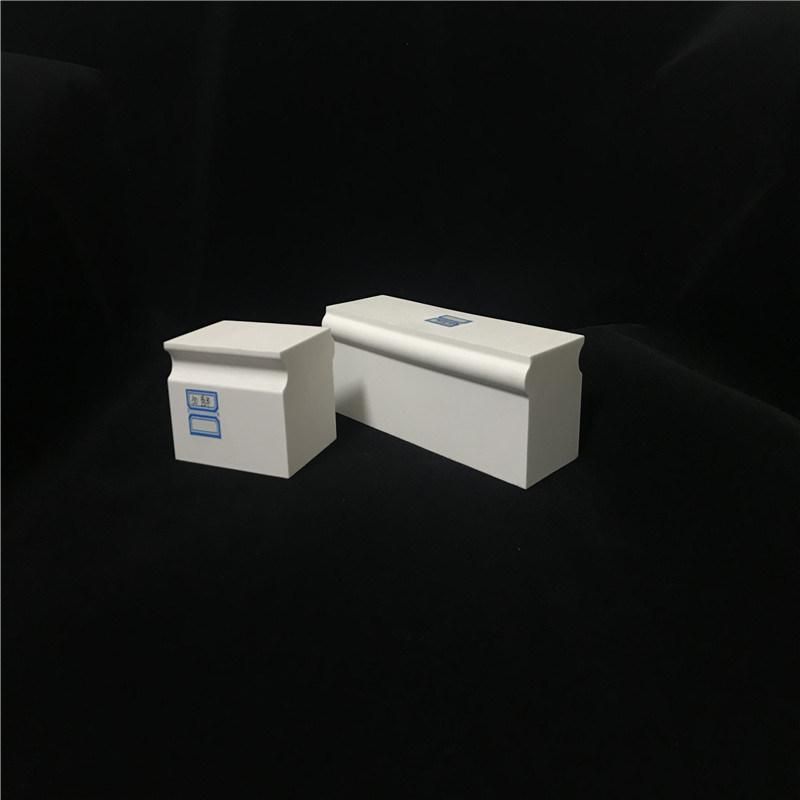

4.Photo for reference.

More Abrasion ceramics products : abrasion ceramics , Alumina ceramics , wear resistant ceramics , alumina pipe liner , ceramic tube , alumina cylinder pipe , wear resistant alumina plate , abrasion ceramic tile , abrasive alumina sheet , friction plain tile , abrasion weldable tile , rubber backed ceramic liner , ceramic composite linings , alumina mosaic sheet , ceramic taper tile for pipe sleeve , ceramic ladder tile for pipe steel , engineering ceramics equipment , pre-fabricated pipe sleeve ,wear resistant bending pipe , abrasion materials.

ZIBO QIMINGXING NEW MATERIAL is located in Zibo, Shandong,Near Qingdao port. With an excellent geographical location and a convenient logistics system,This enable us to provide you varies transportation modes (by express/air/sea) according to your needs. Also, ensure us OTD and save your shipping cost. Our 86700 m2 factory has obtained ISO 9001 and ISO 14001 certification and employs over 350 staff members who enable us to provide you with fully custom services upon request.

We accept customized designs, packing, logo or custom material. We can make custom design based on your inquiry. We provide NDA agreement to keep your design in private.

Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee your satisfaction.

Our business staff have 7~10 years of experience in the industry and can provide you with quality services. All your inquiries will be responded within 24 hours.

PROFESSIONAL

FULL SERVICE

PROTECTION FOR YOUR BENEFIT

Learn more about pipe tile liner with following FAQ

FAQ---(Frequently Asked Questions )

Q 1---Why Choose our :

We can afford the standard and pre-engineered tiles

We can afford the fabricated and lined equipment to customer requirement

We have professional technical team to afford the design drawings for the pre-engineered tiles

We have sincere spirits to offer the better quality ceramics , keep your order delivery smoothly

Q 2---- What's Guarantee of sold Ceramics products ?

1) we have professional technicians team to inspect the property when buy raw material

2) Before mass production , we often make sample for test to avoid production problem

3) During half-finished producing process , we have technicians to test the sizes

4) After mass production , we have technicians to test finished ceramics property , and ask

Workers to select the unqualified products in appearance

5) At the same time , salesman will go to workshop for quality checking

6) Before delivery , we often the test reports for customers

Q3----What's the characters for curved pipe liner

ceramic pipe tile liner is of wear resistance , impact resisting, easy operation, etc.,

is ideal surface abrasion resistant material of bulk material transfer equipment in iron & steel works,

thermal & power plants, port and terminals , cement.

Q4----What's the difference bewteen ceramic curved plate and alumina plain tile

Alumina Ceramic curved plate fabricated as pipe linings for its radian

and angle specially designed , best choice of cyclone , bend pipe, orifice , transition , inner cone

ect equipment

Q5----- What;s the size of alumina cermaic curved liner ?

more sizes and customized size acceptable

Q6-----Any other pipe tile introduced ?

Ys , besides alumina ceramic curved tile , we can offer trapezoidal tile for pipe system ,and ceramic pipe ring available.

Any more questions available by your inquiry. we will reply you soon .