Surface Polishing by Cast Steel Shot Blasting Abrasive on Auto Part

Jinan Junda Industrial Technology Co., Ltd.- Natural Abrasive Type:Bearing Steel Grit

- Artificial Abrasive Type:Artificial

- Application:Marble and Granite Cutting

- Function:Saw Cutting

- Source:Artificial Abrasives

- Particle Size:Abrasive

Base Info

- Model NO.:G25, G40, G50

- Hardness:40-50HRC, 50-51HRC, 60-68HRC

- Product/Kew Word:Bearing Steel Grit

- Shape:Angular,Full Angular

- Density:7.4 g,cm3

- Durability:>3200 Times

- Cr:1.0 -1.50%

- C:0.80 -1.20%

- Mn:0.6 -1.20%

- S:Less Than 0.05%

- Standard:SAE J444,ISO 9001

- Test Standard:SGS

- Si:0.4-1.2%

- P:0.05%

- Application1:Cutting Marble

- Application2:Sandblasting

- Business Type:Manufacture

- Transport Package:25kg Bags, 1 Ton Bag

- Specification:1.0mm, 0.7mm, 0.5mm

- Trademark:Honest Horse

- Origin:Shandong

- HS Code:720510

- Production Capacity:3000 Tons ,Month

Description

Application 1.Blast cleaning: Used for blast cleaning of casting, die-casting,forging; sand removal of casting, steel plate, H type steel, steel structure.

2..Rust removal: Rust removal of casting, forging, steel plate, H type steel,steel structure.

3.Shot peening: Shot peening of gear, heat treated parts.

4.Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure.

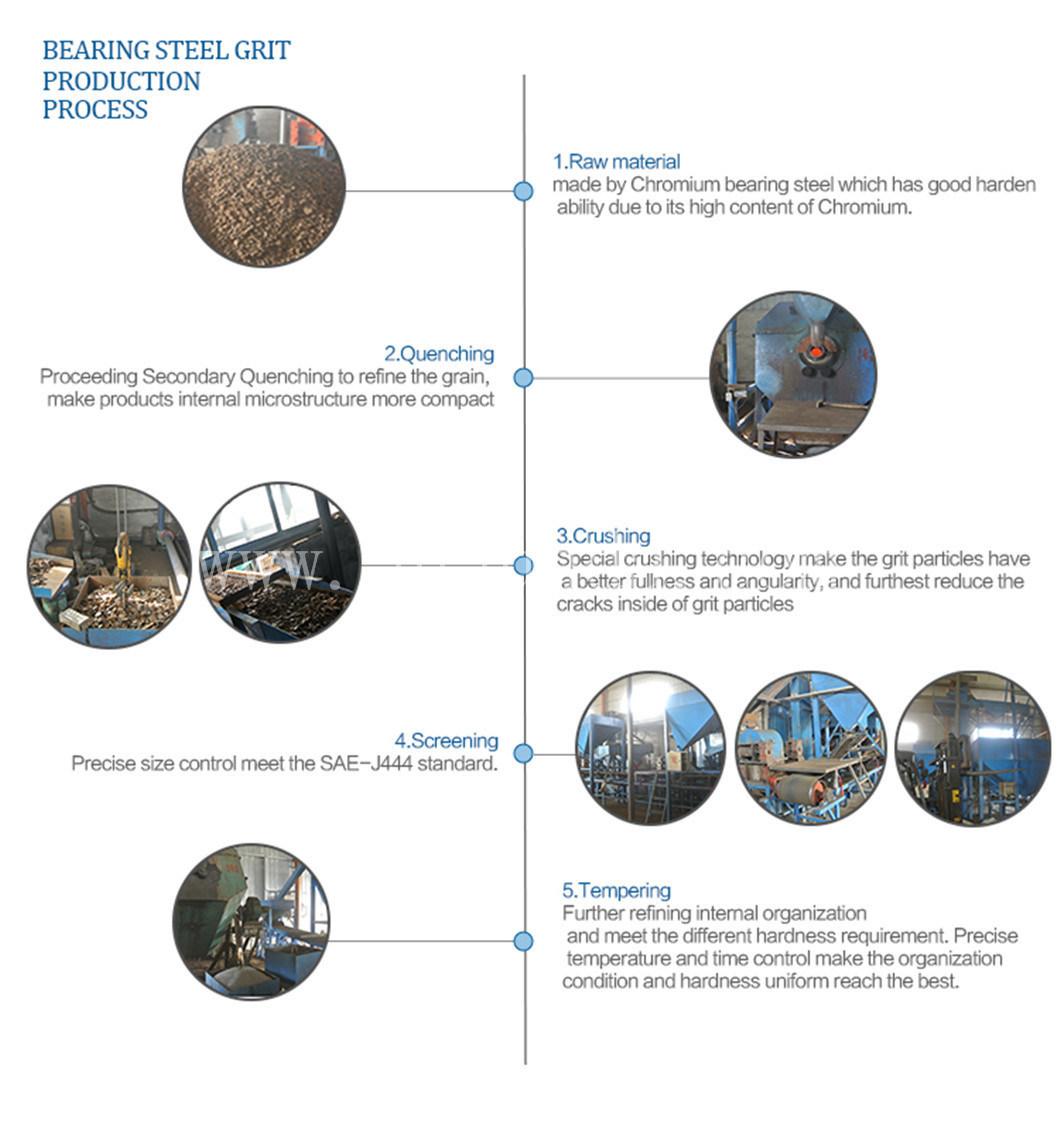

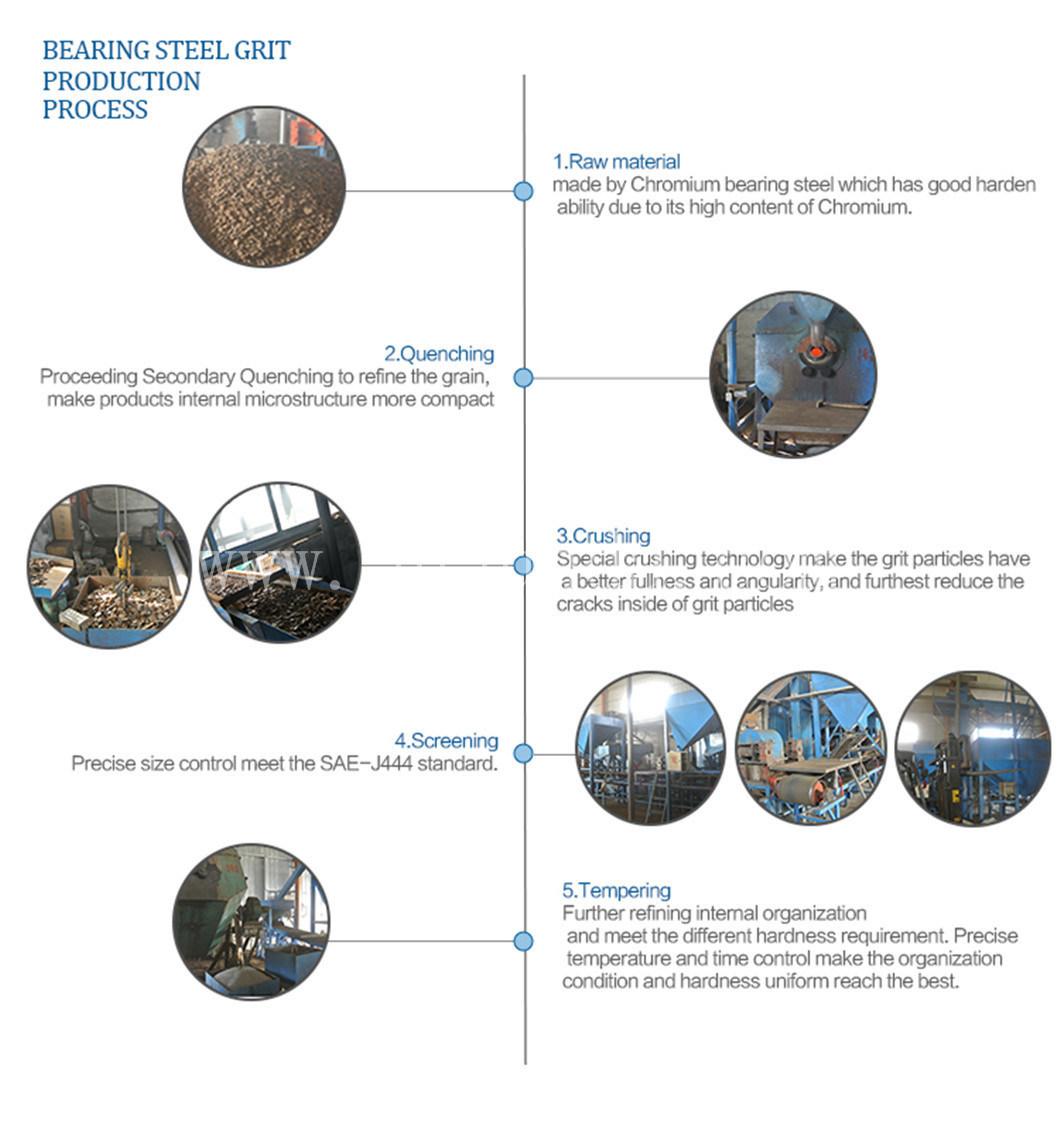

4.steel grit product process

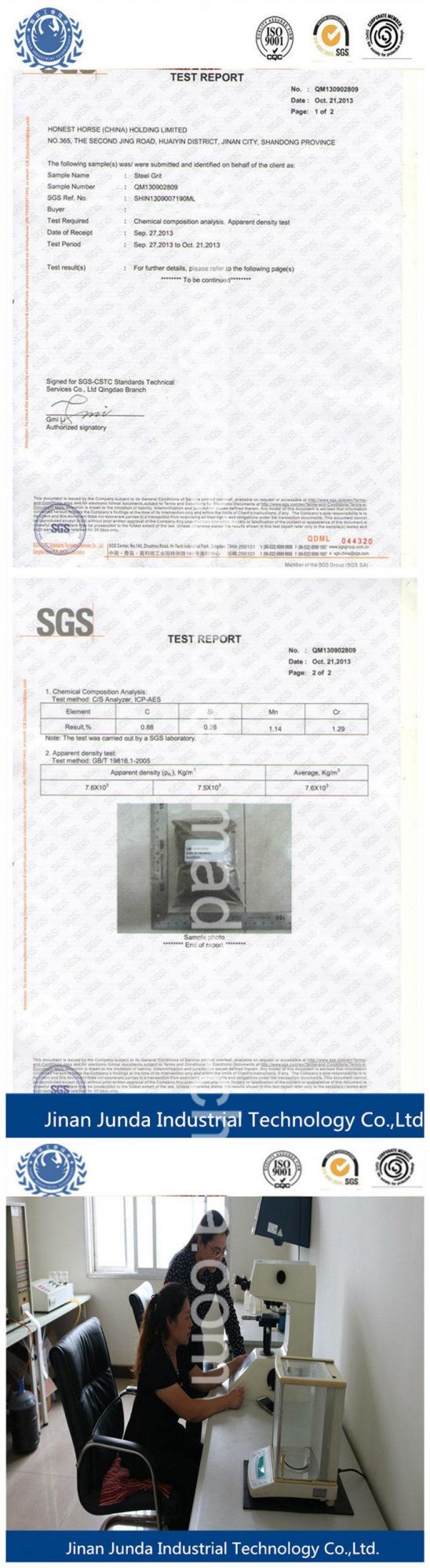

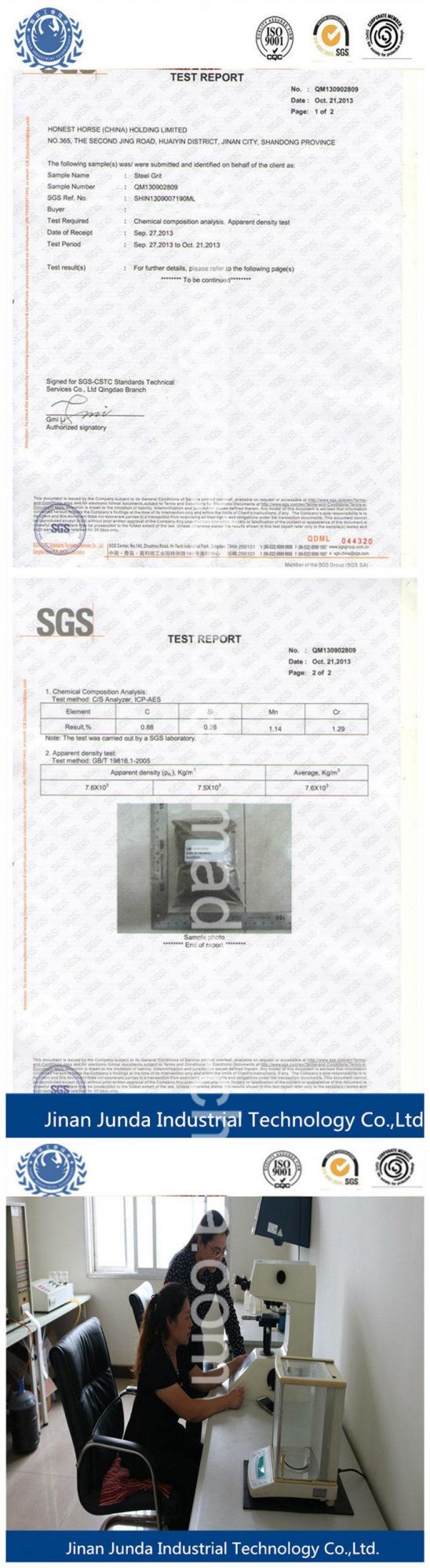

5.Steel grit test equipment and test report

6.Steel grit Applications

Bearing steel grit Cr element is 1-1.5%, fatigue life is 3200 times.

Bearing steel grit quality used for sand blasting body section directly affect the quality and comprehensive cost factor in terms of the sand blasting efficiency,girder coating, painting, kinetic energy and abrasive consumption.

It is specifically for stone cutting.

To cut granite cutting from water jet flow, in this process, stone sawing grit there is no chemical change, and has advantages of no affection on the chemical and physical performance of stone materials , no heat deformation ,narrow lancing, high precision,smooth cutting surface ,cleanness and no pollution, etc.

7.Steel grit package

1.25kg/bag(pp bag or paper bag) then 40 bags in one ton bag/pallet ,

2.one ton one bag

all packages are lined with waterproof materials

We can also pack according to your requirement.

8.Our service

1.we can supply sample for free.

2.Customized Service

a.Product---We can produce various size abraisve according to the customers' requirements.

b.Package---The products can be packaged as customers' requirements.

3.After-sales Service

a.Our products passed ISO9001 standard, and we control the testing procedure strictly.

b.If there are quantity problems,package problems,delivery problems,or any other problems,our

company will seriously investigate the event and give customers a satisfying reply.

9.FAQ

1.Our payment terms:

a.T/T 50% advance payment then the rest 50% payment pay us when get the scanned B/L from our E-mail

b.L/C 100% irrevocable L/C at sight

2.Delivery time:

3-5 work days after get the advance payment

3.Advantages:

15 years exprierence

SAE ISO9001 certificate

on-time shipment

support after-sale service

10.Steel grit customers visit our factory

OUR MAIN PRODUCTS:

2..Rust removal: Rust removal of casting, forging, steel plate, H type steel,steel structure.

3.Shot peening: Shot peening of gear, heat treated parts.

4.Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure.

4.steel grit product process

5.Steel grit test equipment and test report

6.Steel grit Applications

Bearing steel grit Cr element is 1-1.5%, fatigue life is 3200 times.

Bearing steel grit quality used for sand blasting body section directly affect the quality and comprehensive cost factor in terms of the sand blasting efficiency,girder coating, painting, kinetic energy and abrasive consumption.

It is specifically for stone cutting.

To cut granite cutting from water jet flow, in this process, stone sawing grit there is no chemical change, and has advantages of no affection on the chemical and physical performance of stone materials , no heat deformation ,narrow lancing, high precision,smooth cutting surface ,cleanness and no pollution, etc.

7.Steel grit package

1.25kg/bag(pp bag or paper bag) then 40 bags in one ton bag/pallet ,

2.one ton one bag

all packages are lined with waterproof materials

We can also pack according to your requirement.

8.Our service

1.we can supply sample for free.

2.Customized Service

a.Product---We can produce various size abraisve according to the customers' requirements.

b.Package---The products can be packaged as customers' requirements.

3.After-sales Service

a.Our products passed ISO9001 standard, and we control the testing procedure strictly.

b.If there are quantity problems,package problems,delivery problems,or any other problems,our

company will seriously investigate the event and give customers a satisfying reply.

9.FAQ

1.Our payment terms:

a.T/T 50% advance payment then the rest 50% payment pay us when get the scanned B/L from our E-mail

b.L/C 100% irrevocable L/C at sight

2.Delivery time:

3-5 work days after get the advance payment

3.Advantages:

15 years exprierence

SAE ISO9001 certificate

on-time shipment

support after-sale service

10.Steel grit customers visit our factory

OUR MAIN PRODUCTS:

- Cast steel grit

- Steel shot

- Bearing steel grit

- Low carbon steel shot

- Garnet sand

- Glass beads