Premium Polycrystalline Diamond Powder by Blasting for Semiconductor

SINO ZHENG INDUSTRIAL INC.- Type:Diamond

- Classification of Diamond:Artificial

- Characteristic:Hight Temperature

- Characteristics of Natural Diamond:Hight Pressure

- Application:Superfine Polishing

- Delivery Time:3-5 Business Days

Base Info

- Model NO.:HID PD

- Transport Package:Bottle

- Specification:ISO 9001

- Trademark:Harmony

- Origin:Zhengzhou China

- HS Code:71051020

- Production Capacity:1, 000, 000 Carat,Year

Description

Particle Size Distribution Specification for Superabrasive Grains

Feature:

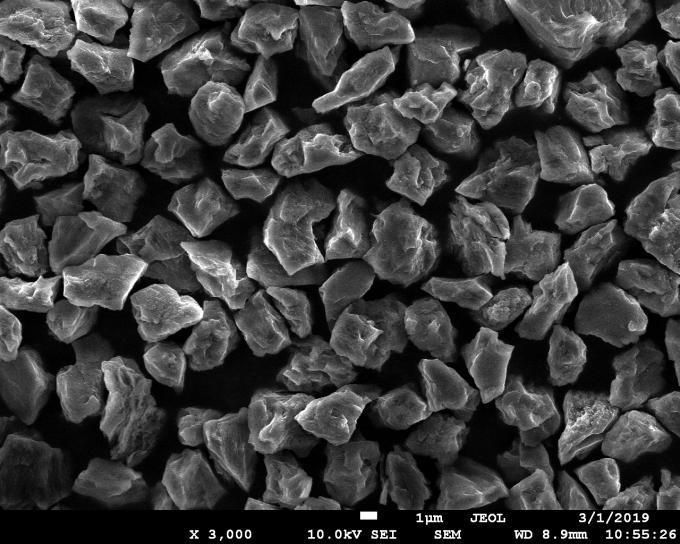

Tight, customized particle size distribution

Blocky and rough particle surface

Stringent oversize control

Low scratch count

Self-sharpening with high material removal rate

Characteristics:

- Detonation synthetic polycrystalline diamond micropowder has the expensive and rare polycrystalline structure of black natural diamond, which is dark gray, metallic luster, good toughness, and has the characteristics of automatic cutting edge.

- Compared with impact synthetic static pressure or natural single crystal diamond, silicon oxide, corundum and other abrasive materials, the grinding efficiency of polycrystalline diamond is 2 to 4 times higher.

- The grinding precision of polycrystalline diamond is unprecedentedly improved.

A. When using 2~4μm polycrystalline diamond powder to grind the workpiece, R<1.6nm.

B. When using 0~0.5μm polycrystalline diamond powder to grind the workpiece, Ra=1.3~1.4nm

C. When using 0~0.125μm polycrystalline diamond powder to grind the workpiece, Ra<0.1nm

D. Due to the "ball" shape of the polycrystalline diamond surface, no scratches will be left on the surface of the workpiece to be polished, thereby improving the polishing yield.

E. Polycrystalline diamond powder can also be plated on the inner wall of a workpiece (such as a cylinder) through an electroless plating method, and its wear resistance is better than any other material.

Application for Polycrystalline Diamond Powder HID PD:

- Polishing sapphire, silicon, ceramics, metals, etc.

- Processing of magnetic head materials, antimagnetic films (MR), multilayer films, sputtering films, molecular beam epitaxy (MBE), ferrite and printing plates.

- Processing fiber optic connectors, laser rods and other products that require certain light waves to pass through.

Workpieces Processing

- Silicon wafers, monocrystalline and polycrystalline silicon, semiconductor wafers, photovoltaic wafers

- Sapphire phone screen, sapphire mobile phone screen saver, camera sapphire screen protective film

- Sapphire mobile phone camera protective film, mobile phone cover glass, sapphire watch mirror

- Precision cemented carbide, precision ceramics, optical glass and lens, etc.