- Model NO.:KS-CB01

- Processing Type:Rolling Type

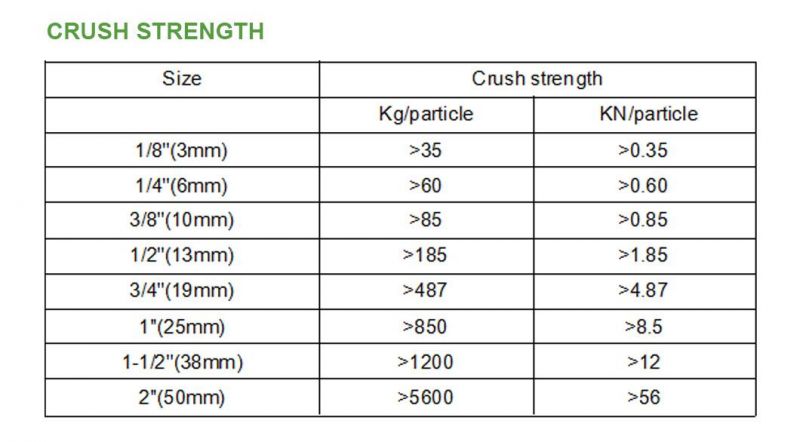

- Size:6mm-75mm

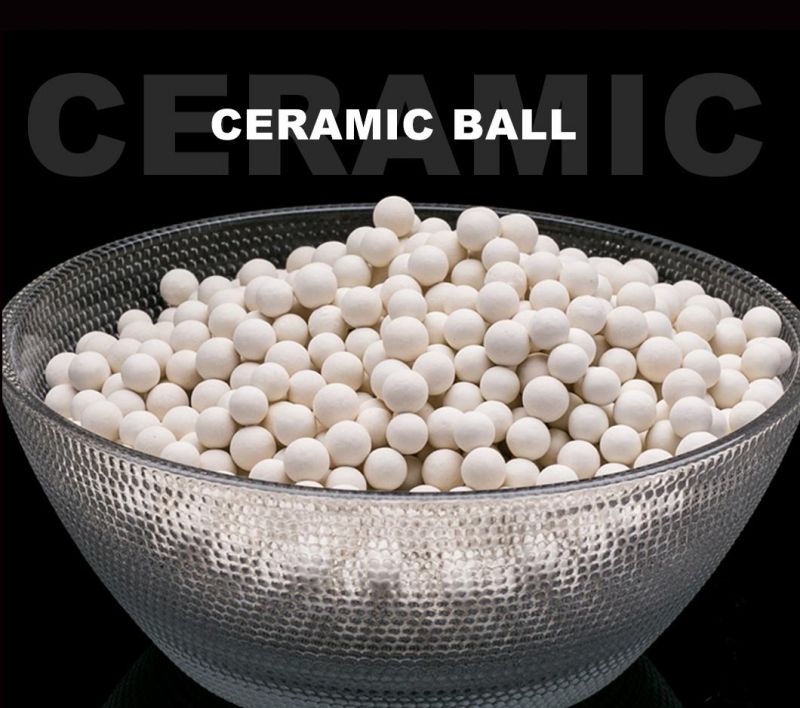

- Color:White

- Customized:Customized

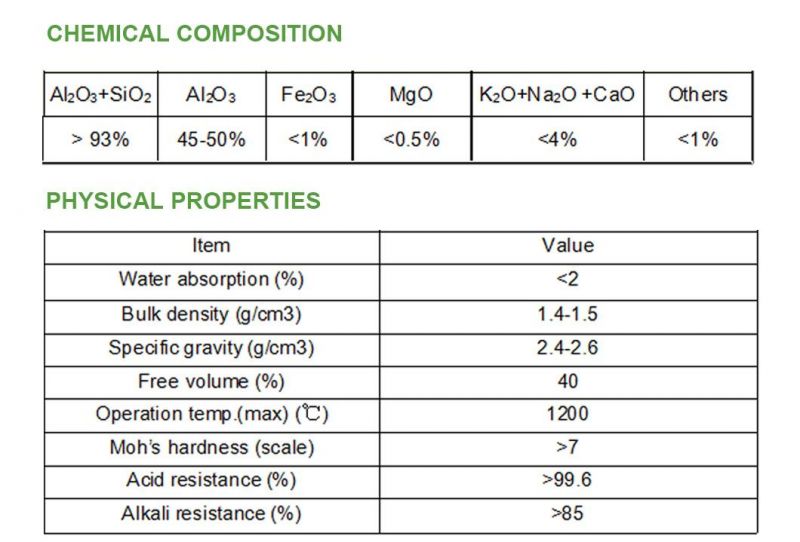

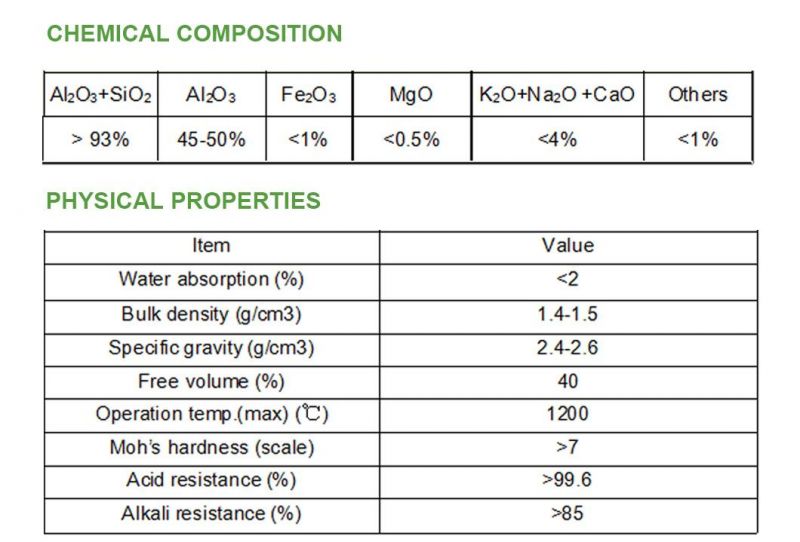

- Moh′s Hardness Scale:7.5

- Acid Resistance:99.8% Min

- Character:Heat Resistance, Chemical Resistance

- Max. Operating Temperature:1550

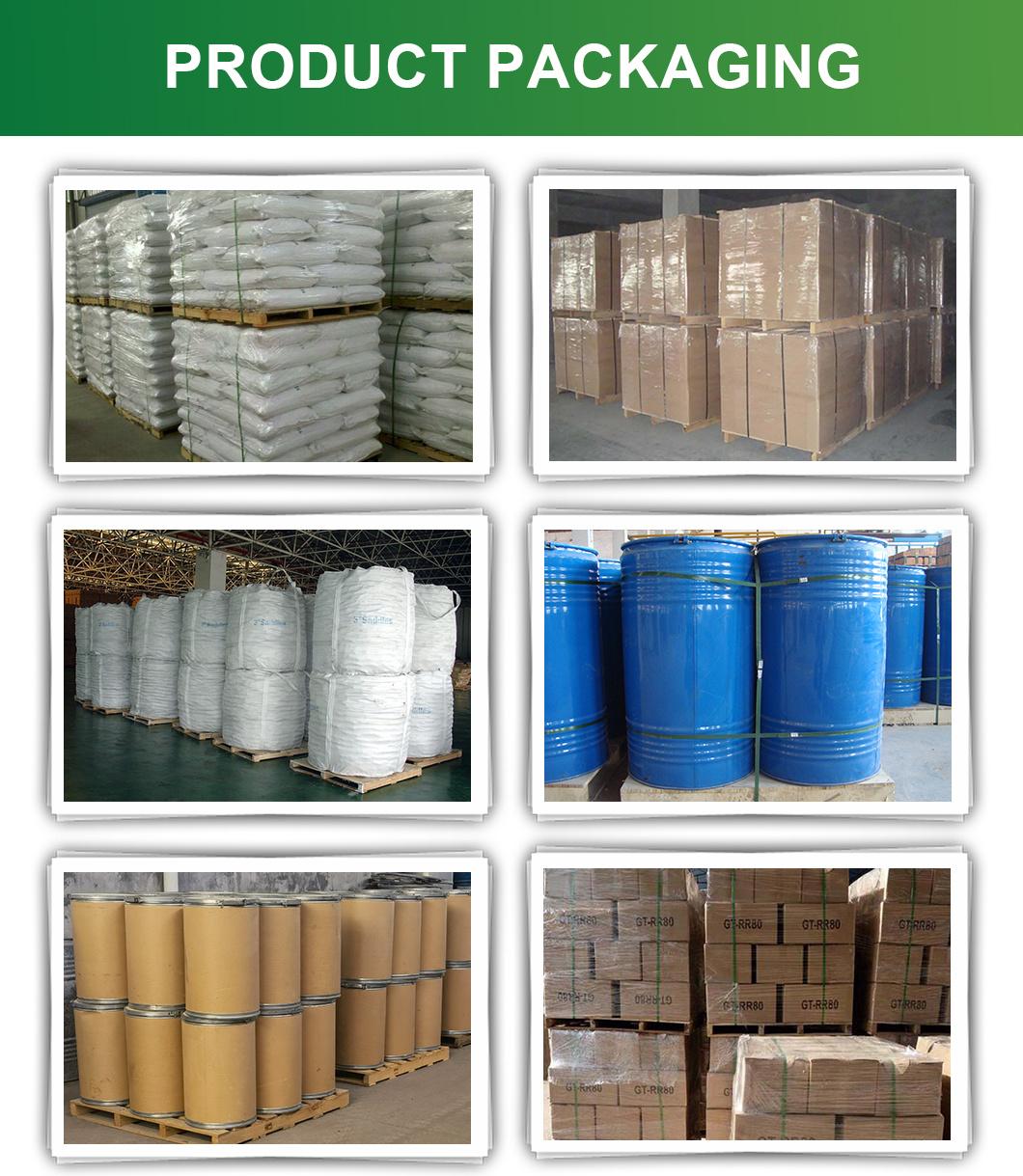

- Transport Package:Plastic Bag, Super Sack, Steel Drum

- Specification:6mm-75mm

- Trademark:KSOURCEEP

- Origin:China

- HS Code:6909190000

- Production Capacity:300-500 Ton,Per Month

- Package size per unit product:10.00cm * 10.00cm * 10.00cm

- Gross weight per unit product:2.000kg

Basic Info.

Model NO.

KS-CB01

Processing Type

Rolling Type

Size

6mm-75mm

Color

White

Customized

Customized

Moh′s Hardness Scale

7.5

Acid Resistance

99.8% Min

Character

Heat Resistance, Chemical Resistance

Max. Operating Temperature

1550

Transport Package

Plastic Bag, Super Sack, Steel Drum

Specification

6mm-75mm

Trademark

KSOURCEEP

Origin

China

HS Code

6909190000

Production Capacity

300-500 Ton/Per Month

Packaging & Delivery

Package size per unit product

10.00cm * 10.00cm * 10.00cm

Gross weight per unit product

2.000kg

Product Description

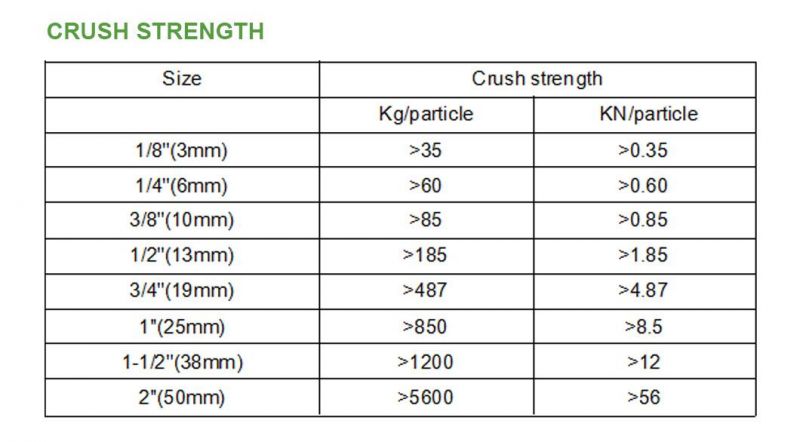

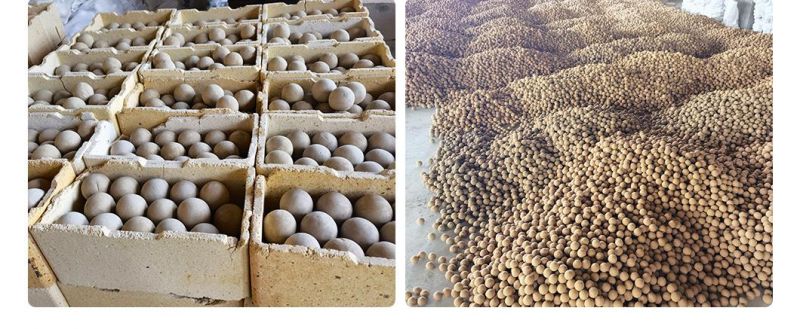

Ksourceep Medium-Alumina Ceramic Ball for Catalyst Alumina Balls

Products introduction:

Medium aluminum balls (medium aluminum ceramic balls) are widely used in ball mill ceramics, petroleum, fine chemicals, building materials, metallurgy, machinery, electronics and many other fields. They have high hardness, high specific gravity, good high temperature performance, high mechanical strength, and no pollution to materials. , Good wear resistance and other advantages, it is currently the most expensive grinding body on the market. And in isostatic pressing, aluminum grinding balls can improve the efficiency of ball grinding better than natural pebbles and silicon carbide balls. Under the conditions of rotation speed, material ball, and water ratio, the grinding time can be shortened, the output of a single machine can be increased, and the cost of ball milling can be greatly reduced.