Tungstenn Carbide Rotary Burrs Set

Zhuzhou Jinxin Cemented Carbide Group Co., Ltd.- Materials:Tungsten Carbide

- Certification:ISO

Base Info

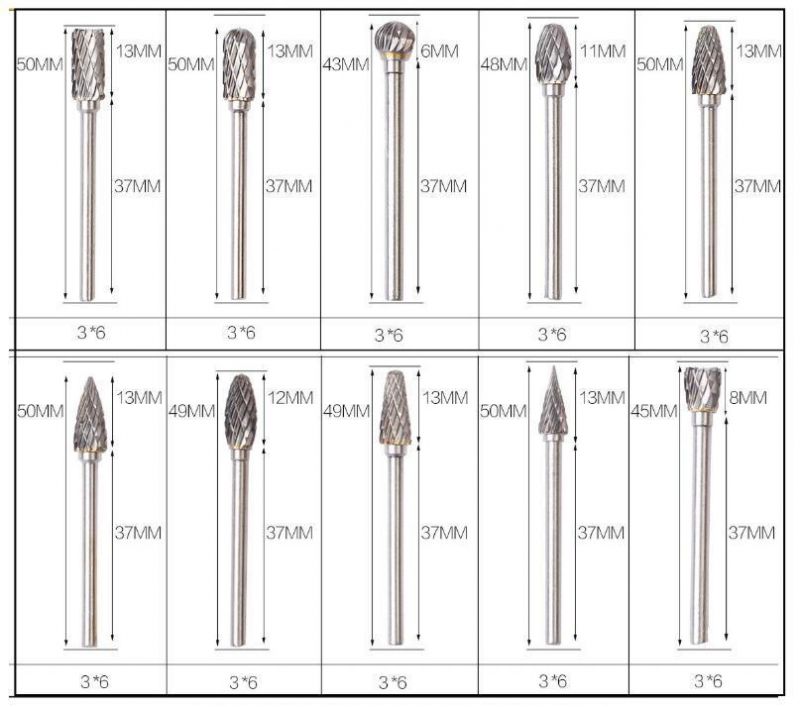

- Model NO.:3*6mm burr set

- Shape:Cylindrical

- Applications:Electric Grinder

- Standard:Standard

- Transport Package:Carton

- Specification:3*6mm set

- Trademark:neutral

- Origin:China

- HS Code:82090090

- Production Capacity:100000000 PCS

- Package size per unit product:10.00cm * 10.00cm * 5.00cm

- Gross weight per unit product:0.200kg

Description

Basic Info.

Model NO. 3*6mm burr set Shape Cylindrical Applications Electric Grinder Standard Standard Transport Package Carton Specification 3*6mm set Trademark neutral Origin China HS Code 82090090 Production Capacity 100000000 PCSPackaging & Delivery

Package size per unit product 10.00cm * 10.00cm * 5.00cm Gross weight per unit product 0.200kgProduct Description

Product description:Carbide burs/porting tools for metal working. Manufactured on premium automated CNC machines, carbide burs are available in three main styles of cuts - single, double and aluminum.

Single-cut burs are for general purpose work and provide good material removal.

Double-cut burs produce smaller chips for greater operator control on applications such as stainless steels and ferrous materials.

Aluminum-cut burs have a wide flute design for easy stock removal without loading on applications such as nonferrous and soft

materials. Feature:

1. Material: 100% virgin raw material with submicron grain size;

2. Grade: Various grades for choice;

3. Advanced production equipments and testing equipments

4. Precision Ground and polished;

5. High wear resistance,high hardness and impact toughness;

6. Samples & small orders are acceptable. Application:Tungsten carbide rotary bur is an effective way to realize merchanization in hand work operations, in the industries of airplane,ship building,automobile, machinery , chemistry, dental, etc. Cemented arbide rotary burrs can be widely used in maching iron,steel casting, carbon steel, alloy steel, stainless steel, copper aluminium , etc.

Warm tips:

1.Must wear protection cover when operating and cut

2.Extending cutter should be moderated when operating

3.Adopt different speeds of level according to processing materials