Nut Paste Making Colloid Mill and Emulsifying System

Zhejiang L&B Machinery Co., Ltd.- Type:Mill

- Power Source:Electricity

- Object:Milling Cutter

- Application:Daily Use

- Disc(Wheel) Type:Grinding Disc

- Material:Stainless Steel

Base Info

- Model NO.:GMT series

- Working Style:High-speed universal

- Disc Diameter:230mm

- Variable Speed:With Variable Speed

- Product Type:Food, Beverage, Dairy Milk

- Name:Tomato Paste Making Machine

- Usage:Industrial

- Contact Material:Ss304 or Ss316L

- Capacity:Customized

- Transport Package:Plywood Case

- Specification:0.1T-10T

- Trademark:BLS,L&B

- Origin:Zhejiang, China

- HS Code:8479820090

- Production Capacity:10PCS,Day

Description

Basic Info.

Model NO. GMT series Working Style High-speed universal Disc Diameter 230mm Variable Speed With Variable Speed Product Type Food, Beverage, Dairy Milk Name Tomato Paste Making Machine Usage Industrial Contact Material Ss304 or Ss316L Capacity Customized Transport Package Plywood Case Specification 0.1T-10T Trademark BLS/L&B Origin Zhejiang, China HS Code 8479820090 Production Capacity 10PCS/DayProduct Description

Introduction:

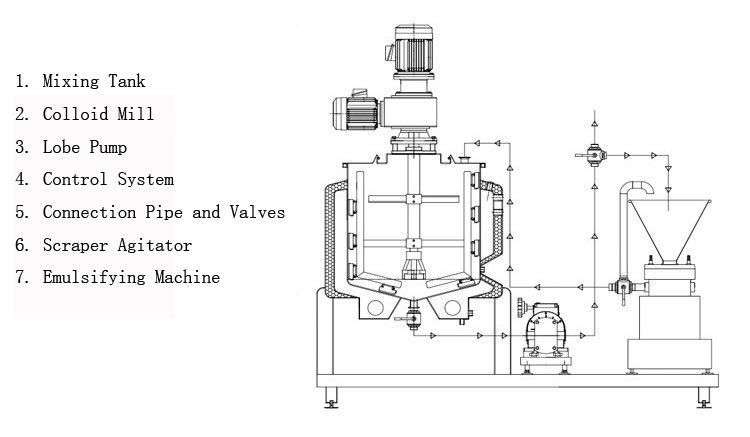

High shear emulsifying mixing tank :which can be with one agitator, two agitator or three agitator, all of these can be design according to client's requirements. According to client's products, the agitator can be high shear emulsifier, can be scraper etc., all of these can be design . And tank can be single layer, double layer or three layer, tank can be with electric heating function or steam heating function etc.... tank structure also can be design according to client's requirements.

Volume | Dimension of Tank(D*H) | Total Height | Power |

| (L) | (mm) | (mm) | (kw) |

| 100 | 600*550 | 1250 | 0.55 |

| 200 | 700*800 | 1350 | 0.55 |

| 300 | 800*750 | 1700 | 0.55 |

| 400 | 800*800 | 1700 | 0.55 |

| 500 | 840*1000 | 1950 | 0.55 |

| 1000 | 1060*1220 | 2700 | 0.75 |

| 1500 | 1160*1500 | 3000 | 0.75 |

| 2000 | 1340*1500 | 3100 | 1.1 |

| 3000 | 1410*2000 | 3600 | 1.5 |

| 5000 | 1810*2000 | 4000 | 2.2 |

| 10000 | 2300*2440 | 4600 | 3 |

| 20000 | 2640*3660 | 6000 | 5.5 |

Colloid mill :

which works with shearing, grinding high-speed stirring. Grinding process occurs in the relative movement between the two teeth with one revolving in high speed and another still, which makes the materials between the teeth received strong shearing and abrasion in addition to high frequency vibration and high speed seil. The above forces effectively evenly disperse, emulsify , smash the materials.

Model | Emulsified size um | Output T/H | Millstone Dia mm | Cooling water pipe mm | Outlet Dia. mm | Inlet Dia. mm | Speed rmp | Sharp kw | Size mm | Weight KG |

| JML-50 | 2-40 | 0.01-0.1 | 50 | 10 | 20 | 30 | 2800 | 1.5(220V) | 270*500*700 | 55 |

| JML-50 | 2-40 | 10 | 20 | 30 | 2800 | 1.1(380V) | 255*500*700 | 50 | ||

| JML-65 | 2-40 | 0.02-0.5 | 65 | 10 | 20 | 30 | 2800 | 1.5 | 270*500*700 | 57 |

| JML-65 | 2-40 | 10 | 20 | 30 | 2800 | 2.2 | 500*345*675 | 70 | ||

| JMW-80 | 2-40 | 0.3-1 | 80 | 12 | 25 | 48 | 2800 | 3 | 630*380*790 | 75 |

| JML-80 | 2-40 | 12 | 25 | 48 | 2800 | 3 | 335*570*920 | 85 | ||

| JMF-80 | 2-40 | 12 | 25 | 48 | 2800 | 4 | 700*570*920 | 140 | ||

| JMW-100 | 2-40 | 0.5-2 | 100 | 12 | 25 | 66 | 2800 | 5.5 | 680*370*900 | 115 |

| JML-100 | 2-40 | 12 | 25 | 66 | 2800 | 5.5 | 390*645*980 | 145 | ||

| JMF-100 | 2-40 | 12 | 25 | 66 | 2800 | 5.5/7.5 | 800*645*980 | 230 | ||

| JMW-120 | 2-40 | 0.5-3 | 120 | 12 | 32 | 66 | 2800 | 7.5 | 680*370*900 | 120 |

| JML-120 | 2-40 | 12 | 32 | 66 | 2800 | 7.5 | 390*645*980 | 150 | ||

| JMF-120 | 2-40 | 12 | 32 | 66 | 2800 | 7.5 | 800*645*980 | 240 | ||

| JMW-140 | 2-40 | 0.5-4 | 140 | 12 | 32 | 66 | 2800 | 7.5 | 680*370*900 | 160 |

| JML-140 | 2-40 | 12 | 32 | 66 | 2800 | 7.5 | 390*745*1020 | 180 | ||

| JMF-140 | 2-40 | 12 | 32 | 66 | 2800 | 7.5/11 | 800*750*1020 | 290 | ||

| JMF-180 | 2-40 | 1-7 | 180 | 12 | 38 | 100 | 2800 | 11/15 | 900*850*1200 | 360 |

| JMF-200 | 2-40 | 1-10 | 200 | 12 | 38 | 100 | 2800 | 15/18.5 | 900*850*1200 | 400 |

Rotary Lobe pumps Or high Shear Pump:

which basically consist of two lobe rotors which rotate synchronously inside a casing without touching each other.The two rotors divide the rotor chamber into to several smaller rooms and move in order he medium is delivered to the outlet. With this circulation, the medium (material) is delivered through the pump continuously.

lobe pump Model | (L) Capacity / per centum Rotate | (RPA) Speed | (L/H) Flow | (KW) Power |

| BLS-3 | 3L | 200-500 | 300-800 | 0.55 |

| BLS-6 | 6L | 200-500 | 650-1600 | 0.75 |

| BLS-8 | 8L | 200-500 | 850-2160 | 1.5 |

| BLS-12 | 12L | 200-500 | 1300-3200 | 2.2 |

| BLS-20 | 20L | 200-500 | 2100-5400 | 3 |

| BLS-30 | 30L | 200-400 | 3200-6400 | 4 |

| BLS-36 | 36L | 200-400 | 3800-7600 | 4 |

| BLS-52 | 52L | 200-400 | 5600-11000 | 5.5 |

| BLS-66 | 66L | 200-400 | 7100-14000 | 7.5 |

| BLS-78 | 78L | 200-400 | 9000-18000 | 7.5 |

| BLS-100 | 100L | 200-400 | 11000-22000 | 11 |

| BLS-135 | 135L | 200-400 | 15000-30000 | 15 |

| BLS-160 | 160L | 200-400 | 17000-34000 | 18.5 |

| BLS-200 | 200L | 200-400 | 21600-43000 | 22 |