Electric Power Tools Parts 4.5 Inch Aluminum Zirconia Abrasive Grinding Flap Disc Wheels for Brass, Copper, Stainless, Inox

LINYI RUNGE BUILDING MATERIALS CO., LTD.- Material:Alumina

- Abrasive:Normal Abrasive

- Shapes:Section Shape

- Types:Surface Grinding Wheel

- Grain Size:60#

- Cylindricity:<1

Base Info

- Model NO.:115mm 4.5" inch

- Circular Degree:<1

- Technics:Sinter

- Working Style:Surface Grinding

- MPa:Ce En12413

- Certificate:ISO, BSCI

- for Use on:for Use on an Angle Grinder

- Application:Grinding, Blending, Sanding and Finishing on a Wid

- Color:According to Request

- Advantage:Long Life, Fast Speed, High Safety

- Main Market:European and American Countries

- Grit:36#-400#

- Transport Package:200PCS,CTN

- Specification:115x72 teech

- Trademark:OEM

- Origin:Shandong China

- HS Code:6804221000

- Production Capacity:50000PCS,Day

Description

Basic Info.

Model NO. 115mm 4.5" inch Circular Degree <1 Technics Sinter Working Style Surface Grinding MPa Ce En12413 Certificate ISO, BSCI for Use on for Use on an Angle Grinder Application Grinding, Blending, Sanding and Finishing on a Wid Color According to Request Advantage Long Life, Fast Speed, High Safety Main Market European and American Countries Grit 36#-400# Transport Package 200PCS/CTN Specification 115x72 teech Trademark OEM Origin Shandong China HS Code 6804221000 Production Capacity 50000PCS/DayProduct Description

4.5 Inch Aluminum and Zirconia Abrasive Grinding Flap Disc Wheel for aluminum, brass, and copper

WITH MPA EN12413 CE, ISO, BSCI CETIFICATES- Constructed of industrial grade premium zirconia for strength, durability, and extended disc life

- 40 grit flap disc is coarser in build and is ideal for heavier stock removal

- Bevel Type 29 disc build is effective for countours, edge and weld blending, and radius grinding

- Resin fiber construction with fiberglass backing plate absorbs vibrations without smear during usage

- Each disc measures at 4-1/2-inch diameter with a 7/8-inch arbor size, making it compatible with grinders operatable of up to 13, 300 RPM

Specification:

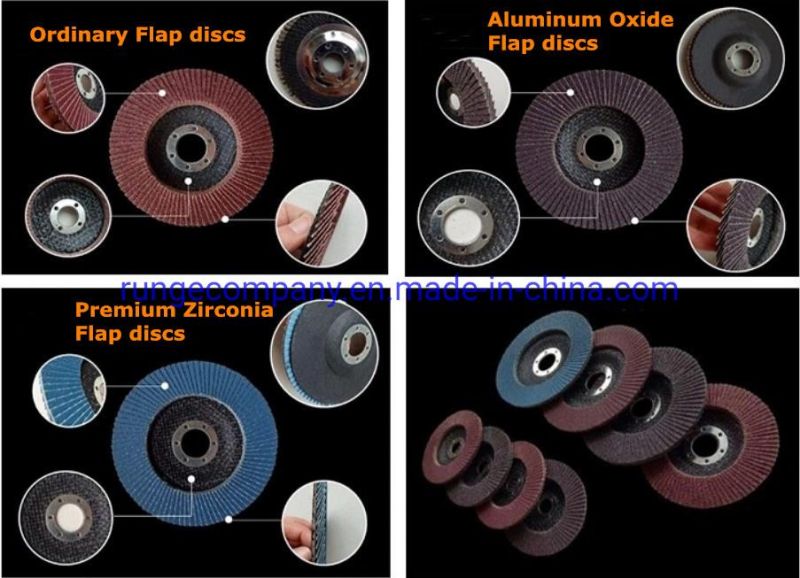

1).Aluminum Oxide Flap Disc with Fiberglass Backing /Plastic Backing

Application: suitable for metal, wood .... polishing;

| Inch Size | Metric (mm) | Max.Speed | Material | Grit |

| 4" x 5/8" | 100 x 16mm | 15200 | Aluminum Oxide | 36-120 |

| 4-1/2" x 7/8" | 115 x 22mm | 13300 | Aluminum Oxide | 36-120 |

| 5"X7/8" | 125x22mm | 12200 | Aluminum Oxide | 36-120 |

| 6"x7/8" | 150x22mm | 10200 | Aluminum Oxide | 36-120 |

| 7"x7/8" | 180x22mm | 8500 | Aluminum Oxide | 36-120 |

Application: suitable for stainless steel, inox, glass polishing;

| Inch Size | Metric (mm) | Max.Speed | Material | Grit |

| 4" x 5/8" | 100 x 16mm | 15200 | Zirconia Aluminum Oxide | 36-120 |

| 4-1/2" x 7/8" | 115 x 22mm | 13300 | Zirconia Aluminum Oxide | 36-120 |

| 5"X7/8" | 125x22mm | 12200 | Zirconia Aluminum Oxide | 36-120 |

| 6"x7/8" | 150x22mm | 10200 | Zirconia Aluminum Oxide | 36-120 |

| 7"x7/8" | 180x22mm | 8500 | Zirconia Aluminum Oxide | 36-120 |

Advantage:

- Backing Plate:

Flap discs come with aluminum, fiberglass or plastic backing plates. Fiberglass is the most common. Aluminum is sometimes chosen due to no potential fiberglass dust hazards. Plastic backing is becoming more popular with some manufacturers suggesting that the plastic backing can be trimmed to increase working life.

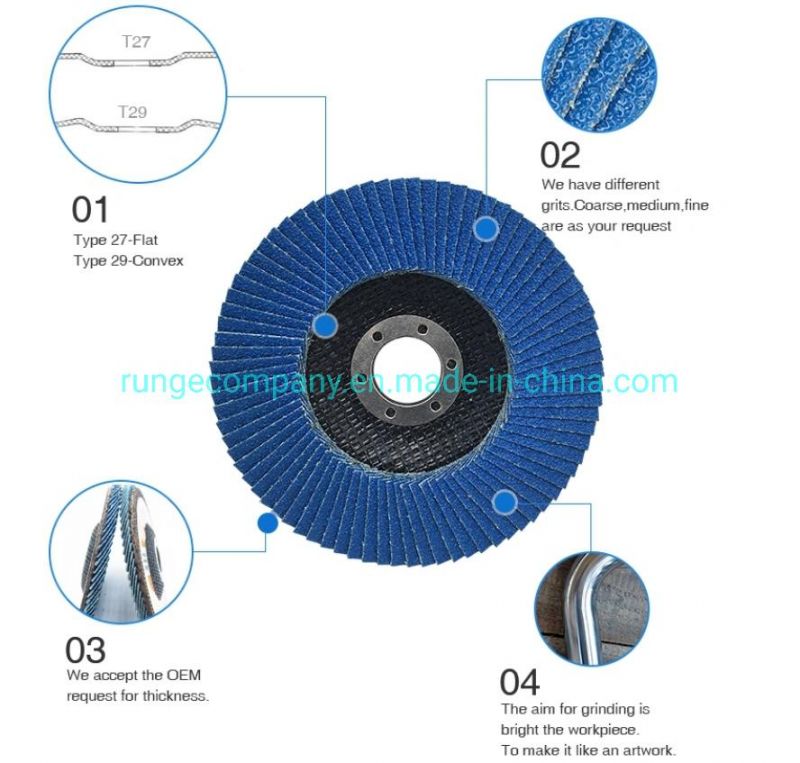

Shape:

Flap discs are broken down into flat and angle face. Following grinding wheel terminology flat discs are type 27 while angle discs are type 29. Typical angle faced flap wheels are about 10°. Angle faced discs are more aggressive and are more suited to stock removal while flat faced discs are better on flat surfaces and will produce a more consistent finish.

Flap Disc Feature:

1.Bonded to extremely strong but durable fibreglass or plastic backing

2.Fast ,aggressive action for high pressure grinding,high efficiency

3.Blending and finishing all in one operation and will reduce process time,lower total grinding cost

4.Maximum contact with work surface with out loading

5.Consistent grinding and finishing performance

6.Excellent performance and efficiencies on stainless and carbon steel application

7.Reduce vibration and noise compared to depressed denter grinding discs.

Application:

Factory:

Workshop:

Warehouse:

Warehouse:

Packing and loading:

Certificates:

FAQ

1. Q: Can we get some samples?

A: We are honored to offer you samples for quality check.

A: Yes, we do, 100% QC inspection Before Shipment.

3. Q: What's the delivery time?

A: It usually takes about 20 days to produce an order from MOQ to 20FT container. But the

Exact delivery time might be different for different orders or at different time.

4. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model

Should not be less than MOQ.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. People always attach great importance to quality control from the

Very beginning to the end of the production. Every product will be fully assembled and

Carefully tested before it's packed for shipment.

6. Q: What are your warranty terms?

A: We offer different warranty time for different products. Please contact with us for detailed warranty terms.

7. Q: What's the payment you accept?

A: As usual our payment is 30%T/T as deposit and 70%T/T seen the copy of B/L. But we could also accept the payment such as L/C, Or Wester Union.