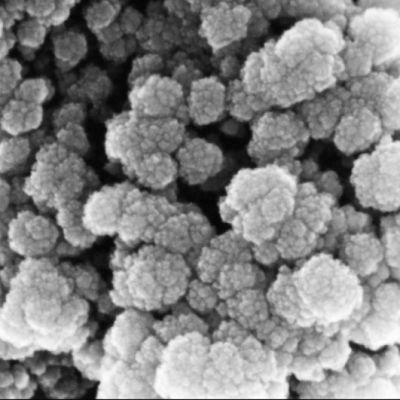

Grey Superfine Ball Shaped 10nm Nano Diamond Lapping Powder

SINO ZHENG INDUSTRIAL INC.- Type:Diamond

- Classification of Diamond:Artificial

- Characteristic:Ultra Detonated

- Characteristics of Natural Diamond:High Toughness

- Application:Superfine Polishing & Lapping

- Color:Dry Grey, Black

Base Info

- Model NO.:HID ND

- Size:5nm - 200nm

- Purity:99.9%

- Function:Outstanding Wearability, Anti-Causticity

- Hardness:Superabrasives

- Particle Size:Powder

- Prodution Method:Ball-Shaped with The Particle Diameter

- Shape:Sphere

- Usage:Lubricating and Antifriction

- Delivery Time:3-5 Business Days

- Shipment:DHL, FedEx, TNT and UPS

- OEM:Available

- Transport Package:Plastic, Bottle, Carton

- Specification:ISO 9001

- Trademark:Harmony

- Origin:Zhengzhou China

- HS Code:71051020

- Production Capacity:200, 000 Carat,Year

Description

Harmony Nanodiamond Powder Series:

- Dry black powder

- Black suspension

- Full specifications dry grey powder

- Full specifications grey suspension

Characteristics:

Basic particles are sphere shape diamond crystals with size 5-20nm

High hardness & wearing resistance of diamond

High specific surface area, porous structure

High heat stability, excellent thermal conduction

Peculiar anti-causticity

Special surface modification treatment makes stable dispersing in both water & oil medium

Superhigh purity, main metal impurity below ppm, purification and surface modification treatment for different needs make surface functional group controllable

Mature stable grading technics make our products suitable for all fields requiring strict PSD

Application for Nanodiamond Grade HID ND:

1. Super fine polishing. The surface roughness of polished workpieces could reach angstrom-level without scratches, which can satisfy the most rigorous polishing applications demand.

2. Lubricating and antifriction. Nano diamond can be used as lubricating oil additives. The sliding friction will be changed into rolling friction. Which can reduce the friction coefficient and significantly improve the friction performance and also prolong the service life.

3. Composite plating and spraying on the surface of various workpieces. Nano diamond can enhance wear resistance, corrosion resistance, impact toughness and hardness of the workpieces' surface,

4. As rubber and plastics additives, nano diamond can significantly enhance its wear resistance, puncture resistance, tensile property and also slow down the ageing process.

5. High purity nano diamond will not cause biological rejection, meanwhile it can be widely used in medical, biological and cosmetic fields because of its big specific surface area, strong adsorption potential.