ISO9001 Standard Grinding Media Abrasive Grains Cast Steel Shot S110 for Metal Parts Surface Polishing Sandblasting

Jinan Junda Industrial Technology Co., Ltd.- Shotblast Type:Shot Blasting

- Shotblast Material:Steel Shot

- Sandblasting Type:Manual Sandblasting

- Shotblast Application:Auto Parts

- Sandblasting Method:Dry Spray

- Sandblasting Applications:Shot Blasting Steel Structure

Base Info

- Model NO.:S110

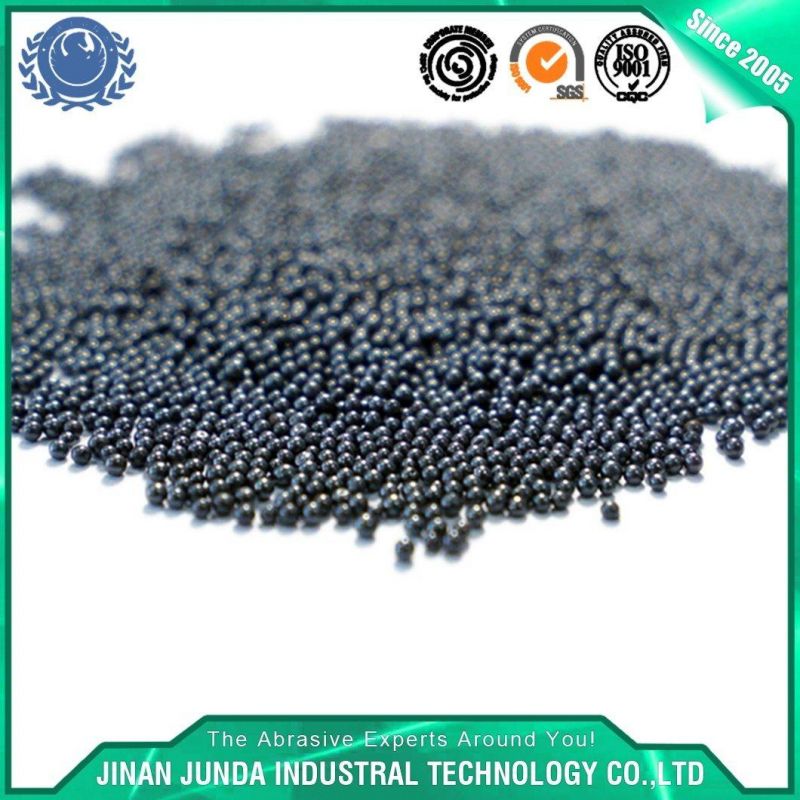

- Product Name:Steel Shot S110

- Color:Black

- Shape:Spherical

- Certificate:ISO9001;SGS

- C:0.8-1.2%

- S,P:<0.05%

- Mn:0.6-1.2%

- Cr:0.26%

- Microstructure:Martensite

- Type:Manufacturer

- Micro Structure:Martensite Structure

- P:<0.05%

- Density:7.6g,cm3

- S:<0.05%

- Lifetime:2500-3000 Times

- Transport Package:25kg Per Bag

- Specification:S110

- Trademark:Honest Horse

- Origin:Shandong

- HS Code:720510

- Production Capacity:3000 Tons Per Month

Description

3.Steel shot Production Process

4.Steel Shot Picture

5.Steel Shot Certificate and Testing

6.Steel shot Normal Packaging

1.25kg per bag(pp bag or paper bag), then 40 bags put in a 1000kg (2200lb) bulk bag.

2.25 kg per bag(pp bag or paper bag), then 40 bags shrink wrapped onto a 1000kg

(2200lb) pallet.

3.25 kg per bag(pp bag or paper bag), then 40 bags in one box.

4.One ton one bag.

5.1000kg loose in one ton bulk bag.

6.Gnerally, one 20GP can load 25 tons, 27 tons at most.

All pakages are lined with waterproof materials.

We can also pakage according to costomers' requirements.

7.Our Service

1. Sample Service

2.Customerized Service

3.After-sale Service

8.Company Profile

Jinan Junda Indutrial Technology Co,.Ltd. is located in Jinan , Shandong Province, China,

which is the daughter cmpany of Honest Horse(CHINA) Holding Limited. We are the manuf-

-acturers of abrasives media for 15 years experience in north China.

Our products include bearing steel grit , cast stel grit, steel shot, steel ct wire shot

and garnetsand abrasives.They are widely used in sandblasting, stone gang saw cutti-

-ng, waterjet cutting, water filtration fields.

So far we have almost 15 years experience and our customers spread over 100 countries

around the worldthat distributein Asia, North America, South America and Austrilia, also

in Africa.

The products reach the ISO9001 standard,SAE and always enjoy a good reputation a-

-mony our customers.We welcome customers all over the world do cooperation with us.

8.FAQ

Q. What is the mode of your payment?

T/T: 50% advance payment and the rest 50% payment oay us when you get the scanned

B/L from our E-mail.

L/C:100% irrevocable L/C at sight.

Q. What's the MOQ of your product?

As usual MOQ is 5TONS.Or as your require, we need to calculate the new price to you.

Q. Can you provide the free samples?

Yes, we can send free samples less than 500g to you. Normally, we can send samples

to customer byexpress, such as DHL,TNT,Fedex,Aramex, etc.

Q. What atandars you carring out for your products?

SAE standard and ISO9001, SGS.

9.Contact Information