Diamond/CBN Powder with Titanium Coating /Nickel Coating

KAIFENG BESCO SUPERABRASIVES CO., LTD.- Material:Diamond

- Usage:Polishing, Grind

- Customized:Non-Customized

- Color:Green

- Shape:Irregular

- Product Feature:Perfect Self Sharpen Ability

Base Info

- Model NO.:B1-N60

- Application:Heavy Duty Work

- Date of Delivery:3-5days

- Shipment:EMS, DHL, UPS, TNT, and FedEx

- Transport Package:Box

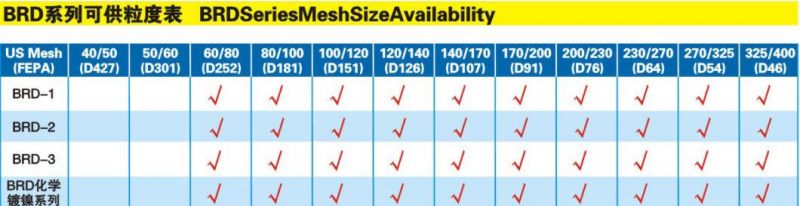

- Specification:BRD-2 TI26 100,120

- Trademark:BESCO

- Origin:Kaifeng China

- HS Code:71051020

- Production Capacity:15000000,Cts,Year

Description

Basic Info.

Model NO. B1-N60 Application Heavy Duty Work Date of Delivery 3-5days Shipment EMS, DHL, UPS, TNT, and FedEx Transport Package Box Specification BRD-2 TI26 100/120 Trademark BESCO Origin Kaifeng China HS Code 71051020 Production Capacity 15000000/Cts/YearProduct Description

Product DescriptionDescription:The raw material is adopted from high-intensity and low impurity content diamonds;special technologies for high-intensity diamond micro-powder in which the crashing,forming process are quite different from those of other techniques;high intensity,strong grinding,high abrasion-resistance,high purity.

Usage:suggested to be applied in the lapping and fine grinding,abrasion and polishing of metal and ceramic bond parts,fine polishing and super polishing of work-piece;production of abrasive paste and agent.

Why Choose Coated Diamond ?

Excellent Thermal Conductivity.

Excellent Holding Force,Strong Corrosion resistance

High strength,High Grinding Efficiency.

High Durable Degree,easy to trim,extends products lifetime.

Good heat resistance,oil resistance,erosin of Acidproof Alkkali.

Overalls of Coated diamond

1),Coated diamond is through the surface treatment to make other material coated, deposited in the diamond surface, resulting the surface a change of shape, status, and physics or chemical.

2),Coated diamond is through the surface treatment to make other material coated, deposited in the diamond surface, resulting the surface a change of shape, status, and physics or chemical.

3),Coat-nickel diamond: Coat-nickel diamond can effectively improve the maintain force between the diamond and adhesive, prolong the service life. It is available in the manufacture of resin grinding tool.

Coat-titanium diamond: Coat-titanium diamond can change the pyhsical property of diamond grit, prevent being oxidated and carbonized in the high temperature. It can also effectively improve the maintain force between the diamond and adhesive, prolong the service life. It is available in the manufacture of ceramic and metal grinding tool, and brazed tool.

Coated synthetic diamond: divided into electrolytic and chemical plating,it includs Ni coating,Ti coating Cu coating,Cr coating ect.Coated synthetic diamond effectively increase holding force between diamond and bonding,reduce thermal shock,protect diamond against oxidation and graphite,lengthen product lifetime.

Besco Quality Assurance Program

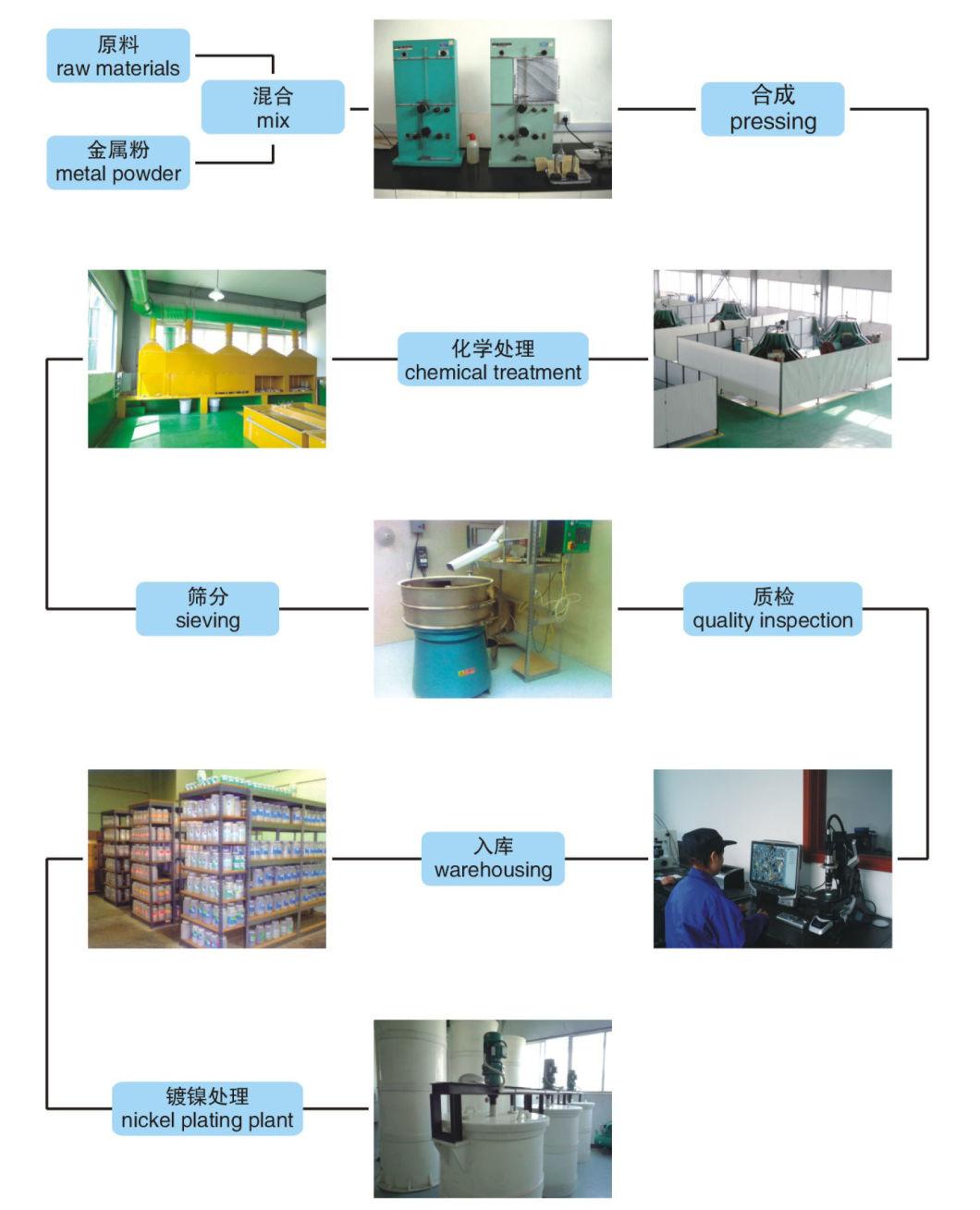

Production Equipment

Besco Superabrasives Co.,Ltd is a leading and professional manufacturer of superabrasives in the world who was established in Kaifeng Economy & Technology Development Zone in 2007 and includes R&D, manufacturing, sales and service. Besco's registered capital is 3 million US dollars and Besco factory covers an area of twenty thousand square meters. After several years development Besco has established three product lines including multinano-crystal diamond, single crystal diamond, CBN and already masters all related core technology.