Aluminum Die Casting Parts Ball Burnishing Vibratory Finishing Machineget Latest Price

Zhejiang Humo Polishing Grinder Manufacture Co., Ltd.- Type:Vibratory Finishing Machine

- Power Source:Electricity

- Object:Parts

- Application:Metal Deburring Polishing

- Disc(Wheel) Type:Curved or U Shape Wall Linear

- Material:Metal

Base Info

- Model NO.:XZG

- Working Style:Shaking

- Disc Diameter:Customize

- Variable Speed:With Variable Speed

- Noise Cover:Airtec

- Speed Converter Brand:Bosch Rexroth

- Power:4.0X2 Kw

- PU Lining Thickness:16mm

- Weight:900 Kg

- Size:2700*1050*1100mm

- Transport Package:Wooden Box

- Specification:900L

- Trademark:HUMO

- Origin:Zhejiang, China

- HS Code:84639000

- Production Capacity:5000

Description

Basic Info.

Model NO. XZG Working Style Shaking Disc Diameter Customize Variable Speed With Variable Speed Noise Cover Airtec Speed Converter Brand Bosch Rexroth Power 4.0X2 Kw PU Lining Thickness 16mm Weight 900 Kg Size 2700*1050*1100mm Transport Package Wooden Box Specification 900L Trademark HUMO Origin Zhejiang, China HS Code 84639000 Production Capacity 5000Product Description

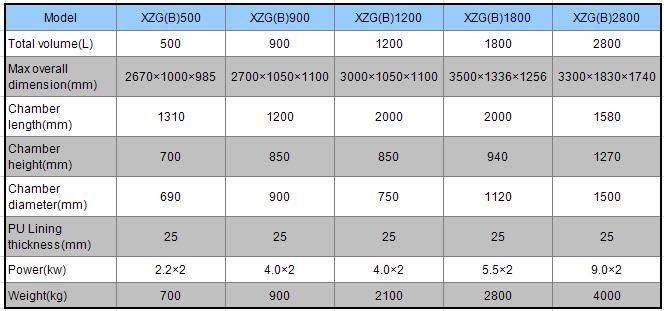

U shape linear type Vibratory finishing machine for Marble StoneStone Ageing Trough Vibratory Finishing Machine Product Description:

XZG vibratory finishing machines are the well-established solution for finishing heavy and large parts. Besides, the straight wall tub vibrators equipped with fixed or removable polyurethane tub dividers prevent parts contacting.

One of the major application of this machine is for marbles tiles aging and antique finishing.

With the stone tumbling process, tiles get stone antique treatment look as if it stands 2000 years of time. These antique looking stones are popular at historical buildings.

We uses variable speed control ensuring optimal tumbling performance. Applications for stone aging finishing includes columns, granite stone, granitic plate, cliff plate, concrete paving stone, drywall marble stone, calcareous sandstone, sidewalks, sculptures, and mosaic tiles.

We are able to process tiles size from 10X10cm to 90X90cm parts with a different model of vibratory tumbling machines. In addition, the Feed-Thu continuous vibratory finishing machine is available for tiles stone production line.

Processing time is according to the surface requirement from 15 min-30 min, or longer. This antique treatment process no needs polishing compound. Tap water is enough for lubrication.

Trough Vibratory Finishing Machine Feature:

- Digital process timer

- Low profile design

- Wide opening for big size parts

- Stress relieved and enhanced with blasting

- Default manual parts media separation

- Extended separation deck

- Wear resistant PU lining from Dow Chemicals

- Two vibrating motors fixed sideways,equipped with adjustable weights,providing stable vibratory force

- Apply dividing bulkheads to create independent treatment areas inside the tank,possible to process delicate components or components of different lots

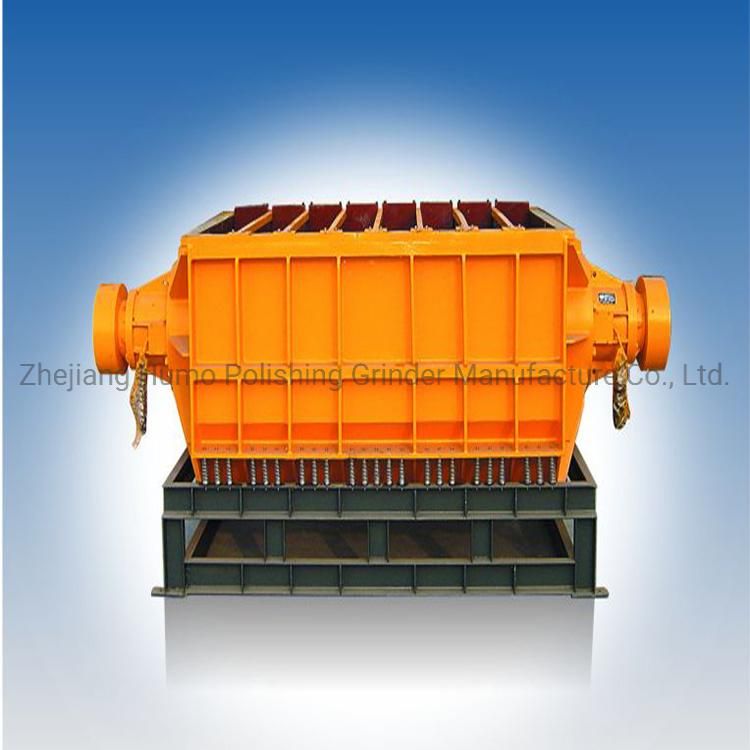

Trough Vibratory Finishing Machine Optional setting:

- Optional Items

- Sound Cover

- Compound Dosing Pump

- Pneumatic flap control

- Variable Frequency Drives

- Control box standing on the floor or hang on the wall

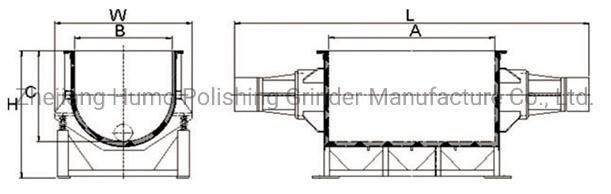

Vibratory Polishing Machine Technical Drawing:

| Model | Total volume(L) | Max overall dimension (mm) | Chamber length A(mm) | Chamber length B(mm) | Chamber diameter C(mm) | PU lining thickness (mm) | Motor(kw) | Weight(kg) |

| XZG(B) 900 | 900 | 2700*1050*1100 | 1200 | 850 | 900 | 25 | 4.0X2 | 900 |

Vibratory Polishing Machine Technical Data:

Vibratory Finishing Equipment Optional settings:

FAQ:

Q: How is HUMO ?

Zhejiang HUMO Polishing Grinder Manufacture Co., Ltd. is famous Top 3 brand mass finishing equipment and consumables manufacturer of China, has:

- 25 years: vibratory finishing machines and tumbling media manufacturer experience.

- 200000 square meters factory

-more than 500 employees

-outputs over 60,000 tons of media chips,over 5000 sets of finishing machines and over 10000 tons of compounds annually

-our products sell well both in domestic and world markets, such as United States of America, Japan, Korea, Australia, Singapore, Malaysia, Turkey, UK, Italy, Spain, Germany, France, Sweden, Switzerland etc, over 50 countries total

Q: What Certifications do you have?

ISO9001, CE, certifications etc. 100% quality check, and testing before shipment.

Q: What is the equipment warranty?

1 year warranty for all Machinery equipment

Q: What is your Payment method?

Accept payment via T/T (Bank transfer), Western Union, Money Gram;

Q: What is your Minimum order amount?

For machine minimum order is 1 PCS. For tumbling media minimum order is 1000kg or 2000 lbs as one pallet.

You can ship less amount of media if ship with the machine.

Sample order is allowed to ship less amount of tumbling media

Q: What is your way of packaging?

Fermentation wooden pallets for media, 1000kg per pallet, 25kg/plastic bag

Wooden box for equipment and compound

Q: How long is your production time?

15 working days for sample order;

20-25 working days for bulk order.

Emergency order can be fulfilled in a week

Q: What is the Shipping Way?

20-30 days by sea to your nearest seaport

2-5 days by air to your nearest airport

3-5 days by express to your doorstep

Q: What is the nearest Port:?

Shanghai, Ningbo and Yiwu are the closest port.