High Zirconia Plus Alumina Oxide Ceramic Grinding Ball CS52 as Ceramic Media for Superfine Mill

Pingxiang Chemshun Ceramics Co., Ltd.- Material:Al2O3 Sio2 Zro2

- Usage:Construction, Machinery, Grind

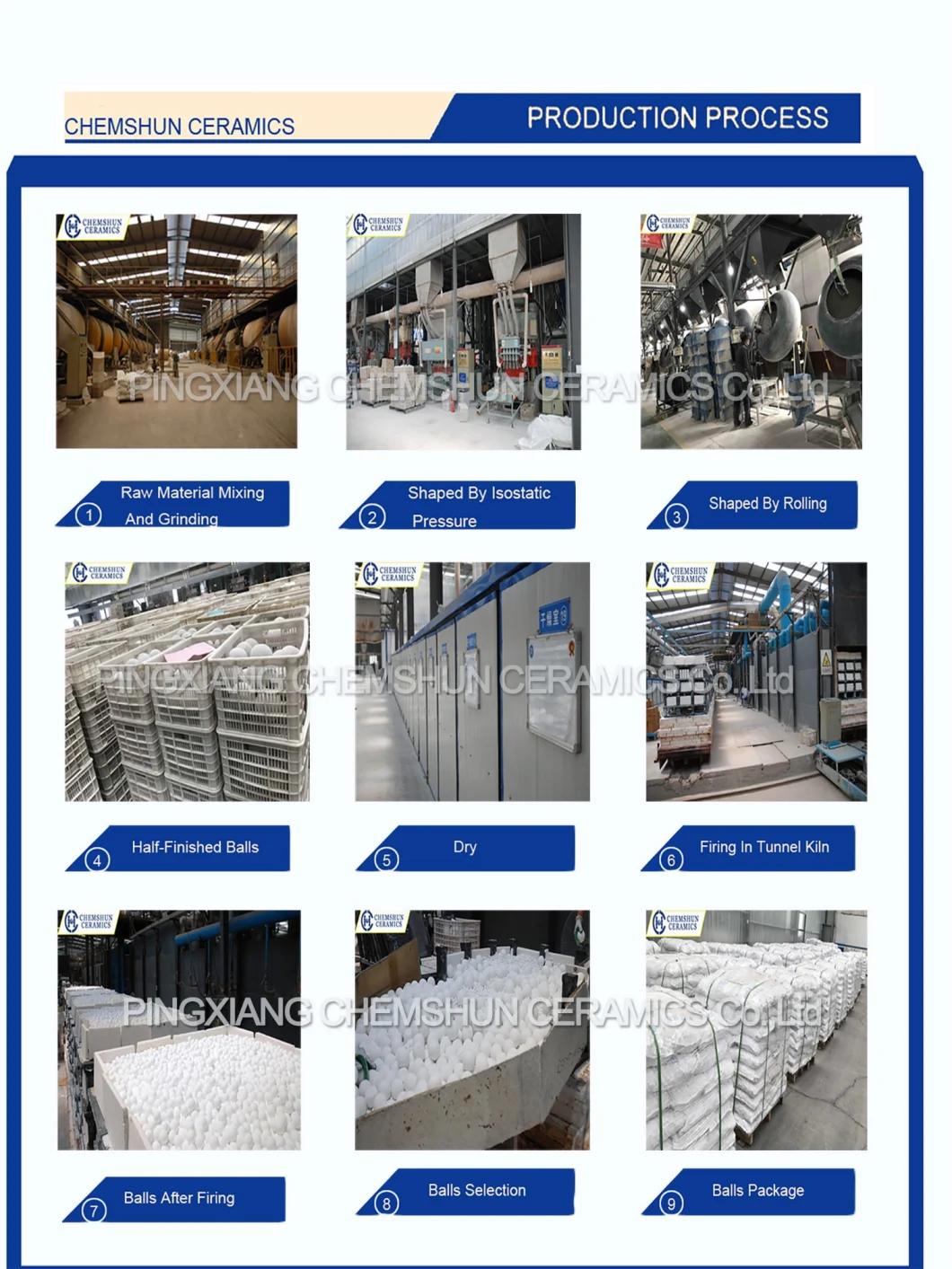

- Processing Type:Rolling or Isostatic Pressing

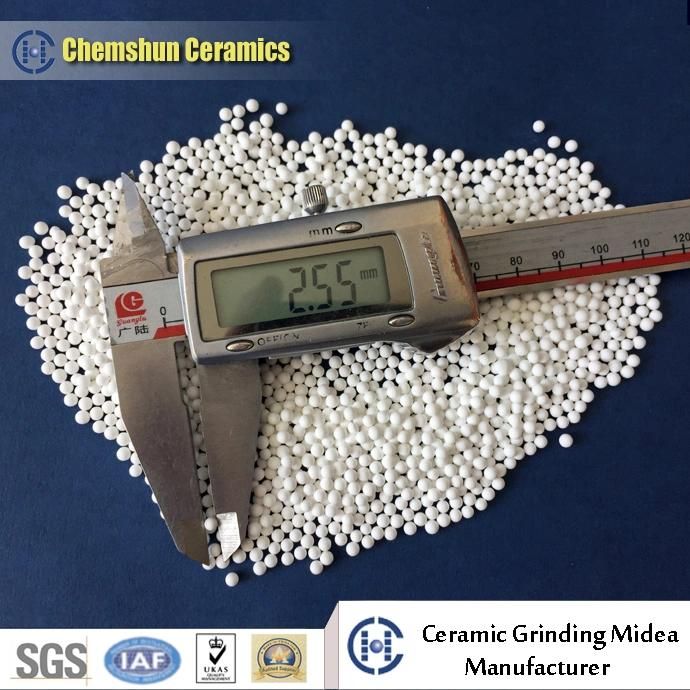

- Size:0.5~20mm

- Color:White

- Customized:Customized

Base Info

- Model NO.:CS52

- Featrue:High Hardness, Medium Density and Anticorrosion

- Application:Mining Machine

- Field:Minings, Minerals, Cements

- Density:5.1~5.3 g,cm3

- Grinding Situation:Dry Grinding, Wet Griding

- Vickers Hardness:900~1000

- Water Absorption:0%

- OEM:Accept

- Transport Package:by Bags, Then Fasten on Pallet.

- Specification:D0.5~D20mm

- Trademark:Pingxiang Chemshun Ceramics

- Origin:P. R. China

- HS Code:69091200

- Production Capacity:2500 Ton , Year

Description

Basic Info.

Model NO. CS52 Featrue High Hardness, Medium Density and Anticorrosion Application Mining Machine Field Minings, Minerals, Cements Density 5.1~5.3 g/cm3 Grinding Situation Dry Grinding, Wet Griding Vickers Hardness 900~1000 Water Absorption 0% OEM Accept Transport Package by Bags, Then Fasten on Pallet. Specification D0.5~D20mm Trademark Pingxiang Chemshun Ceramics Origin P. R. China HS Code 69091200 Production Capacity 2500 Ton / YearProduct Description

High Zirconia Plus Alumina Oxide Ceramic Grinding Ball CS52 as Ceramic Media for Superfine MillDescription:

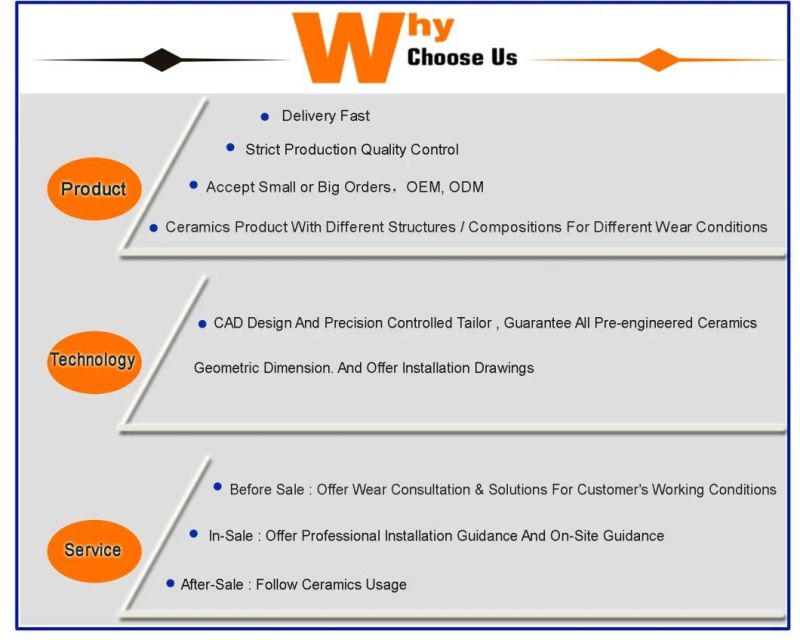

Pingxiang Chemshun Ceramic Co.,ltd is Ceramic Grinding Media manufacturer. To meet the market requirement of different milling applications, Chemshun developed a range of ceramic grinding media with broadest range of size s and densities are available to suit both horizontal and vertically mills for fine & ultra-fine grinding, mixing and dispersing.

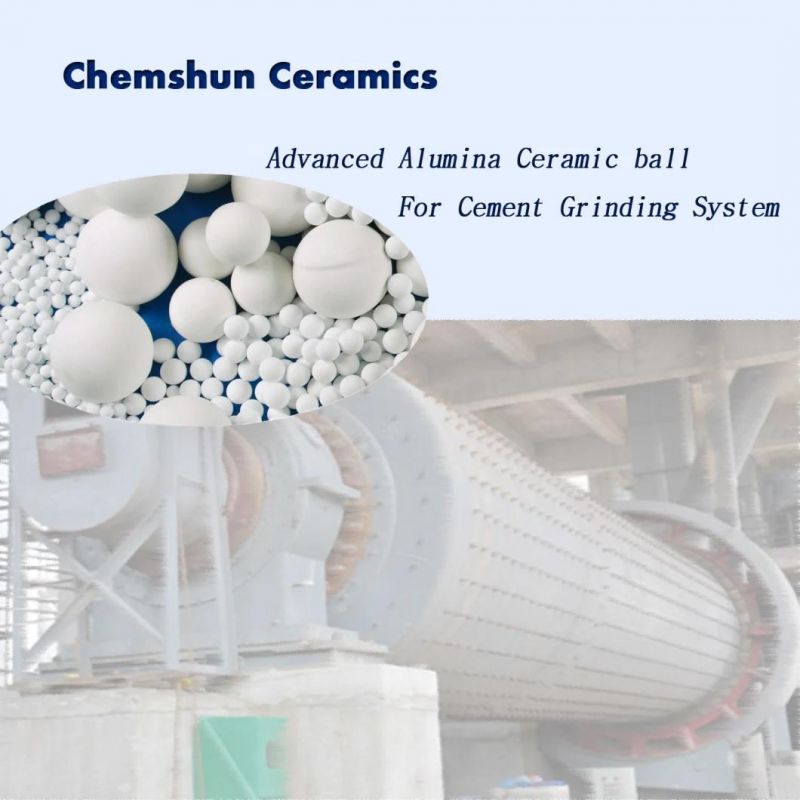

High-performance, high density ceramic grinding media: CS-52, with the best grinding, mixing and dispersing efficiency. This zirconia-based grinding medias is the optimum combination of efficient and cost-effective products to enhance productivity and quality.

| Item | Main | Diameter | Density | Application Suggestion |

| (mm) | (g/cm3) | |||

| CS-52 | ZrO2,Al2O3 | 0.4~5.0 | 5.1-5.3 | It suitable for the hard materials's superfine mills with high speed (up to 14m/S) and high energy input. For example: Outotec's HIG mill. Flsmidth VXP. |

The Benefits:

>High grinding efficiency

>Decreasing product contamination

>Longer product life cycle

>Reduce mill wear and maintenance cost, less down time

>Less energy than steel or iron balls

>Less cost per volume than high-density steel media alternatives

The Features:

>High hardness

>Superior impact and wear resistance

>Uniform size and good roundness

>Inert Chemical and environmentally friendly

>Engineered made

Applications:

>Mining

>Mineral

>Industrial Ceramics

>Electronic Ceramics

>Cement

>Chemical

>Paints

>Inks

>Dyes

>Pigments

>Magnetic coatings

Service:

We have experts team understand your needs supply the engineered great ceramic grinding media for your grinding application.

We offer on-site visiting, lab testing, professional solution for you.

Web:chemshun.en.made-in-china.com .

Export:

Our products have been exported to many countries: Australia, Chile, USA, Russia, UK, Indonesia, etc., good quality have be approved by our clients.