Al2O3 Ao Aluminum Abrasive Nylon Filament for Grinding Polshing Brushes

Chongqing Dami New Material Technology Co., Ltd.- Material:Al2O3

- Shape:Round

- Certification:FDA, CE, ISO

- Length:1250mm

- Transport Package:25kgs,Carton

- Specification:0.3-1.4mm

Base Info

- Model NO.:DM-AO-ABS

- Trademark:DAMI

- Origin:China

- HS Code:5404190010

Description

About Abrasive Filament

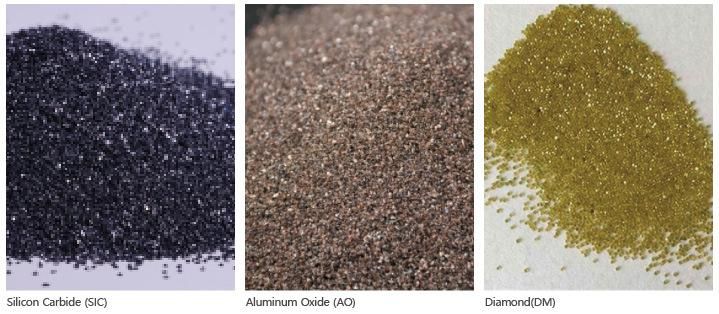

DAMI abrasive filaments are produced by loading abrasive grits such as silicon carbide (SIC) or aluminum oxide (AO), Diamond evenly into high-quality nylon and extruding the mixture into filaments.

DAMI abrasive filaments have superior stiffness, good flexibility, and great elasticity. Brushes made with DAMI abrasive filaments are highly efficient in grinding, finishing, polishing, and deburring in different industries and for different surfaces e.g. curved, concave, convex surfaces or insides of pipes without damaging the dimensions and fineness of the workpiece.

Silicon Carbide (SIC)

Common used abrasive grit is silicon carbide aka SIC grit, which is produced in a resistance type electric furnace with petroleum coke, quartz sand and other materials. SIC is an extremely hard black insoluble crystalline substance. It is used as an abrasive and heat-refractory material and in single crystals as semiconductors, especially in high-temperature applications. Its micro hardness is HV3100-3280, stiffness and hardness is higher than White Alumina. SIC abrasive filament can be widely used to produce industrial brushes for steel, textile, PCB cleaning, stone polishing, and other grinding applications.

PROPERTY COMPARISON OF GRIT

- Vickers hardness (HV): DM > GC > SIC > WA > AO

- Cutting force: DM > GC > SIC > WA > AO

- Price: DM > GC > SIC > WA > AO

PROPERTY COMPARISON OF NYLONS

Bend recovery: PA6<PA66<PA610<PA1010<PA612

Water absorption: PA612<PA610<PA1010<PA66<PA6

Durability:PA6<PA66<PA610<PA1010<PA612

THE BEST ONE IS THE MOST SUITABLE ONE

The most popular abrasive filaments are SIC and AO filaments. SIC abrasive is generally the best choice for the most of the applications. AO is suitable for precision polishing and soft surface. Basically, every industry has its own common-used abrasive filament. For detailed questions, please do not hesitate to contact us for consulting. It would be more helpful, if you can send us some samples for analyzing.

DAMI-BRUSH FILAMENTS EXPERT

Very grateful to our customers for the support and encouragement and bwelcome to give us your support and enquiry.