CNC Milled Parts Abrasive Ceramic Grinding Media Mass Finishing Tumbling

HUZHOU INOVATEC MACHINERY CO., LTD.- Natural Abrasive Type:Natural Corundum

- Artificial Abrasive Type:Corundum Abrasives

- Application:Metal Parts

- Function:Surface Deburring

- Source:Natural Abrasives

- Particle Size:Abrasive

Base Info

- Model NO.:RS

- Hardness:Conventional Abrasive

- Transport Package:Wooden Box

- Specification:20x10x20mm

- Trademark:Inovatec

- Origin:Huzhou, China

- HS Code:68042290

- Production Capacity:20000 Ton

Description

Basic Info.

Model NO. RS Hardness Conventional Abrasive Transport Package Wooden Box Specification 20x10x20mm Trademark Inovatec Origin Huzhou, China HS Code 68042290 Production Capacity 20000 TonProduct Description

CNC Milled Parts Abrasive Ceramic Grinding Media Mass Finishing Tumbling

Catalog Download

https://inovatecmachinery.en.made-in-china.com/Product-Catalogs/

Abrasive Ceramic Grinding Media Product Description:

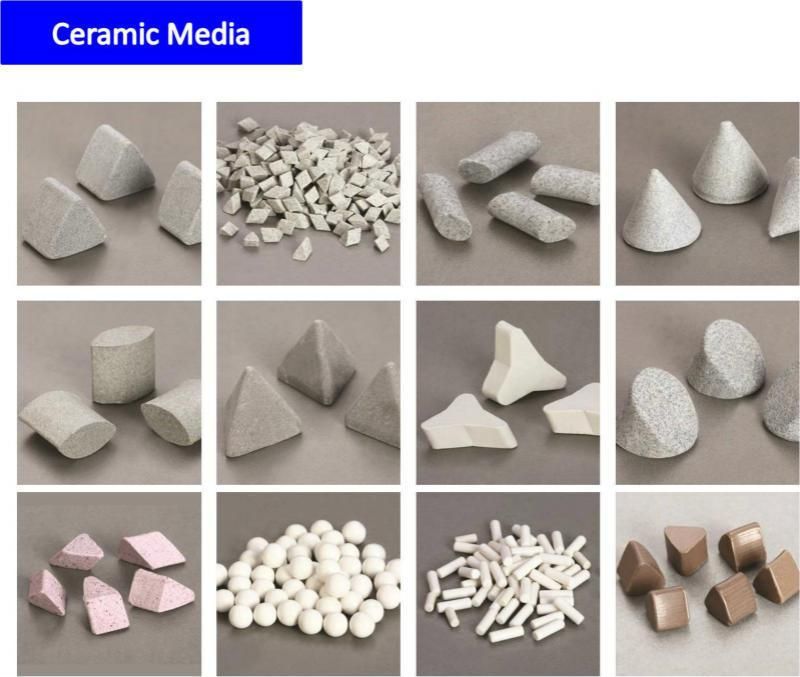

Abrasive Ceramic Grinding Media comes in a wide variety of sizes, shapes, and angles that can increase or decrease its cutting ability. Being a bonded formulated tumbling media, it is more effective and long-lasting.

Usually, people use different recipes for different industrial applications. However, brown corundum is the most common type of abrasive used in ceramic tumbling media. Apart from the type of abrasive material, various other factors including the grit size and shape, size of the tumbling media, and the compound also contribute to its performance.

There are a lot of shapes available, includes Angle cut cylinder, angle cut triangle, straight cut triangle, and ball shape etc.

It is widely used for copper deburring, aluminum deburring, earth chain deburring

Abrasive Ceramic Grinding Media Feature:

- Long Life

- Fast Cutting

- Heavier Than Most Tumbling Media

- Wide Selection of Size and Shape

- Polishing to Aggressive Deburring

- Shorter Process Times

Abrasive Ceramic Grinding Media Application:

- Steel and Titanium Deburring

- Rust Removal on Iron Parts

- Create a Radius

- Edge Rounding

- Remove Machining Marks

- Removing Slag and Grease on Laser Cutting Parts

Abrasive Ceramic Grinding Media Technical Data:

Abrasive Ceramic Grinding Media Product info:

Required finishing results, machine size and the weight of the treated parts, are important aspects in choosing the right media composition and size to achieve the optimum process. Different types of media with varying amounts of abrasive are needed for the various processes.

Rösler manufactures various sizes and compositions of ceramic media in our production facilities. This ensures that the right media is available for each application. Special customer specific solutions can also be produced. Our test labs and our media production facilities work together to develop media that meets special requirements. All consumables - ceramic and plastic media, compounds, and auxiliary media are manufactured to the highest quality standards. Our eight-step quality checks guarantee the consistent quality of our products. All production areas are certified to DIN ISO 9001 standards.

Abrasive Ceramic Grinding Media Company introduction:

Ceramic media for delivery:

Vibratory Finishing Deburring Polishing Successful Project:

Parts before and after vibratory polishing, vibratory deburring, cleaning, edge rounding, descaling, degreasing, de-oiling, cleaning, edge breaking,radiusing:

Mass Finishing Equipment and tumbling media Packing and shipment:

Payment:

FAQ:

Q: How is Inovatec machinery brand?

Inovatec Machinery is famous Top 3 brand mass finishing equipment and consumables manufacturer of China, has:

- 25 years: vibratory finishing machines and tumbling media manufacturer experience.

- 20000 square meters factory

-2 year warranty

Q: What Certifications do you have?

ISO9001, CE, certifications etc. 100% quality check, and testing before shipment.

Q: What is Inovatec Machinery equipment warranty?

2 year warranty for all Inovatec Machinery equipment

Lifetime maintenance will be provided after the 2 year warranty period expires.

Q: How you guarantee tumbling media quality?

We make quality tracking from raw material until quality check before shipment. We keep record of quality test including wearing and cutting.

For bulk and OEM order, we follow your testing methods and keep track of wearing and cutting. If the quality does not meet the standard, we will not make the shipment.

Q: What is your Payment method?

Accept payment via T/T (Bank transfer), Western Union, Money Gram, and PayPal;

Accept L/C at sight (bulk order).

Q: What is your Minimum order amount?

For machine minimum order is 1 PCS. For tumbling media minimum order is 1000kg or 2000 lbs as one pallet.

You can ship less amount of media if ship with the machine.

Sample order is allowed to ship less amount of tumbling media

Q: What is your way of packaging?

Fermentation wooden pallets for media, 1000kg per pallet, 25kg/plastic bag

Customize packaging and logo printing is available for discuss

Wooden box for equipment and compound

Q: How long is your production time?

15 working days for sample order;

20-25 working days for bulk order.

Emergency order can be fulfilled in a week

Q: What is the Shipping Way?

20-30 days by sea to your nearest seaport

2-5 days by air to your nearest airport

3-5 days by express to your doorstep

Q: What is the nearest Port:?

Shanghai, Ningbo and Yiwu are the closest port.

Contact us: