45-55HRC Grinding Rod Used in Rod Mill (from China)

Shandong Huamin Steel Ball Joint-stock Co., Ltd.- Materials:Carbon Steel

- Certification:ISO

- Applications:Mine, Cement, Electric Power Plant

- Shape:Round

- Specifications:40-120mm

- Diameter:40-120mm

Base Info

- Model NO.:40-120mm

- Length:2m -- 6m

- Hardness:45HRC ---55HRC

- Transport Package:Bundle

- Specification:Dia. 40-120mm, Length. 2m-6m

- Trademark:HM

- Origin:China

- HS Code:73261100

- Production Capacity:150, 000 Mt,Year

Description

Basic Info.

Model NO. 40-120mm Length 2m -- 6m Hardness 45HRC ---55HRC Transport Package Bundle Specification Dia. 40-120mm, Length. 2m-6m Trademark HM Origin China HS Code 73261100 Production Capacity 150, 000 Mt/YearProduct Description

1.Features and Advantages of Grinding Steel RodConcentrating on wear-resistant grinding material for 30 years, Shandong Huamin Steel Ball Joint-Stock Co., Ltd is one of the largest grinding rod manufacture in China. We manufacture the product with the length of 2m to 6m and the diameter of 40mm to 140mm. The data is just for reference. The product can also be customized.

After years of research and development, we finally develop the new-type steel grinding rod successfully. The newly developed product is characterized by low wear, unique chemical composition, high hardness of 45HRC to 55HRC, and strong toughness. Meanwhile, via the quenching and high temperature tempering treatment, the internal stress is removed. The product has good straightness, and won't break, bend and come out with two tapering ends. The economic benefit is much in evidence.

a. The blanking of the steel grindng rod is implemented via the sawing machine. The dimensional tolerance would adide by the requirements of the order. After the implementation of blanking, the two ends of the raw material are polished into the R arc via the polishing machine.

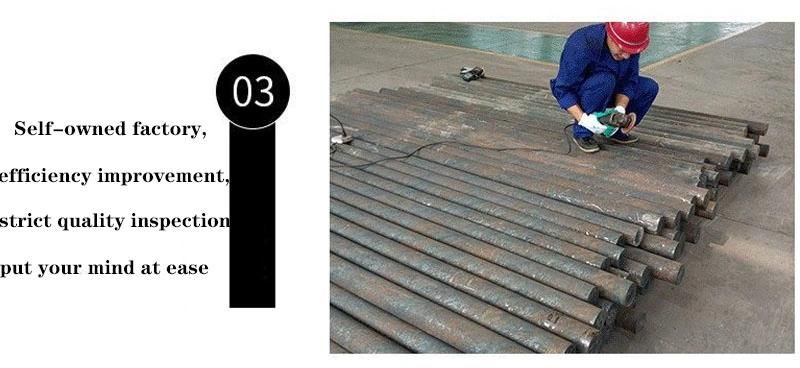

b. The surface of the product for the rod mill cannot have the crack, overburning and fissure visible to the naked eyes.

c. The nonstraightness of the product is less than 0.2%. The diameter tolerance ranges from +0mm to -1.5mm. The length tolerance is fro +0mm-25mm. The fracture should be less than 3%.