92% 95% Industrial Ceramics Alumina Lining Brick for Grinding Mill

Pingxiang Chemshun Ceramics Co., Ltd.- Item:Alumina Lining Brick

- Materials:Alumina

- Alumina Content:92%

- Size:Customized

- Color:White

- Application:Mill

Base Info

- Model NO.:Chemshun Ceramics

- Moh′s Hardness:≥8

- Self Abrasion Loss:<0.02%

- Water Absorption:<0.01%

- Density:3.1-3.3G,Cm3

- Character:High Density, High Hardness, High Wear Resistance

- Transport Package:Carton+Pallet

- Specification:According to your demand

- Trademark:Chemshun

- Origin:China

- HS Code:69091200

- Production Capacity:25000ton,Year

Description

Basic Info.

Model NO. Chemshun Ceramics Moh′s Hardness ≥8 Self Abrasion Loss <0.02% Water Absorption <0.01% Density 3.1-3.3G/Cm3 Character High Density, High Hardness, High Wear Resistance Transport Package Carton+Pallet Specification According to your demand Trademark Chemshun Origin China HS Code 69091200 Production Capacity 25000ton/YearProduct Description

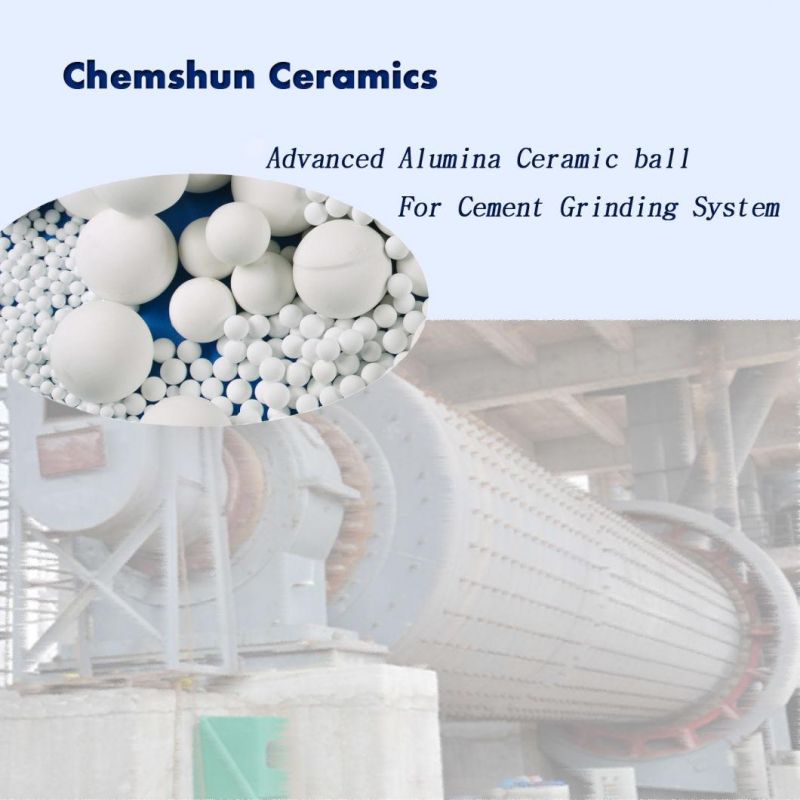

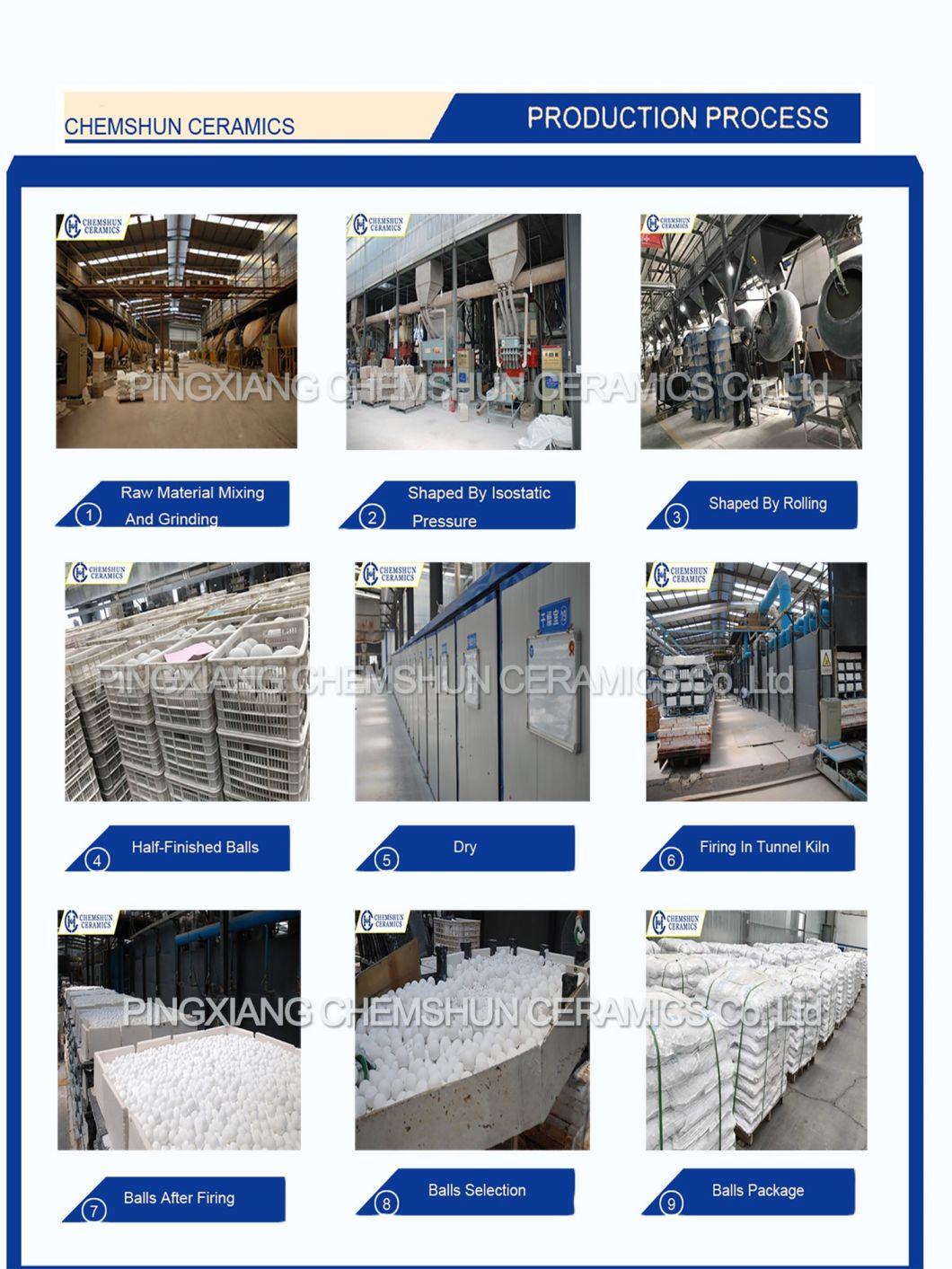

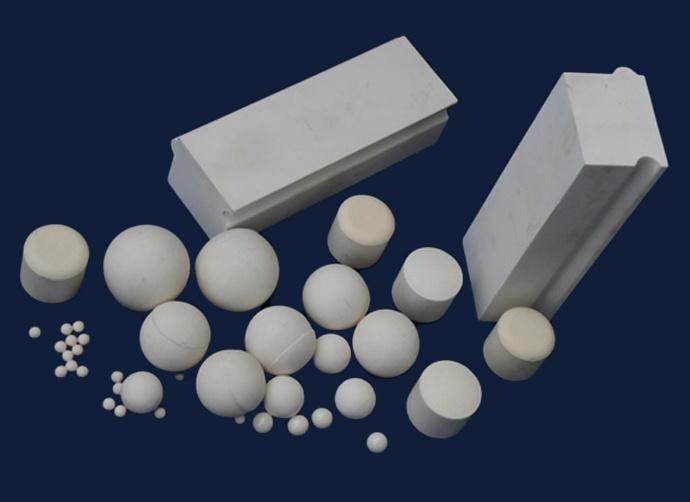

92% 95% Industrial Ceramics Alumina Lining Brick for Grinding MillThe alumina lining brick have these shape Rectangular brick, half rectangular brick, ladder brick, thin brick and half ladder brick, with the advantage of high density, high hardness, low abrasion loss, anticorrosion and the good shape, it used for ball mill as the wear-resistance lining, widely used in ceramic, cement, paint, chemical, pharmaceutical, coating etc. The lining brick can effectively improve the grinding efficiency, reduce the grinding cost and product pollution.

The ceramic grinding media are the abrasive media for ball mills and grinding machines(wet grinding/dry grinding) in Ceramic, cement, pigment, chemical, metallurgy industries. It is an ideal ball mill grinding media that can improve grinding efficiency and keep no contamination to your product.

Character:

1. High density

2. High hardness

3. High wear resistance

4. High grinding efficiency

Main classification:

Alumina Grinding Media, Alumina Lining Brick, ZrO2 Grinding Media

| Item | Name | Length | Height | a-width | i-width |

| A | Rectangular brick | 150 | 50/60/70 | 50 | 50 |

| B | Half Rectangular brick | 75 | 50/60/70 | 50 | 50 |

| C | Ladder brick | 150 | 50/60/70 | 50 | 45 |

| D | Thin bric | 150 | 50/60/70 | 22.5 | 21 |

| E | Half ladder brick | 75 | 50/60/70 | 50 | 45 |

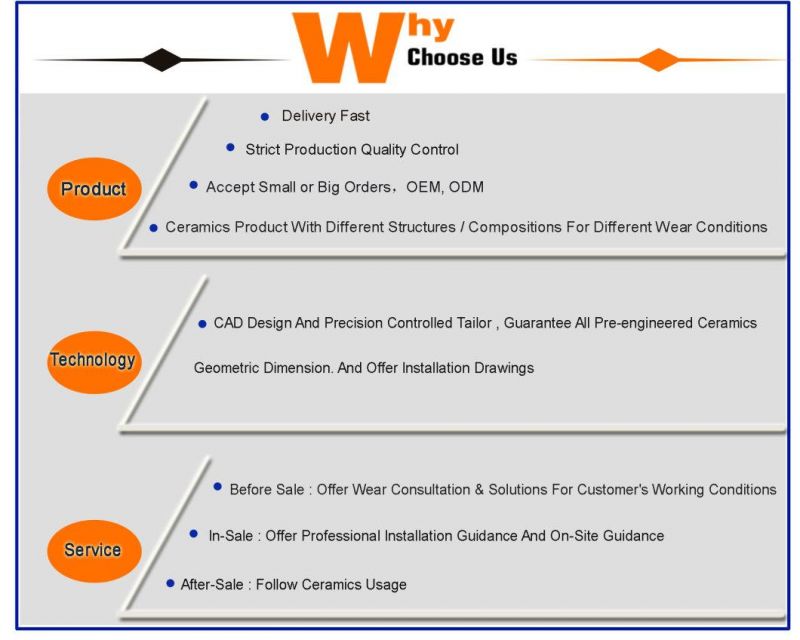

The Benefits:

1. High grinding efficiency

2. Decreasing product contamination

3. Longer product life cycle

4. Reduce mill wear and maintenance cost, less down time

5. Less energy than steel or iron balls

6. Less cost per volume than high-density steel media alternatives

Service:

We have experts team understand your needs supply the engineered great ceramic grinding media for your grinding application.

We offer on-site visiting, lab testing, professional solution for you.

Web:chemshun.en.made-in-china.com .