Best Horizontal Glass Edging Polishing Grinding Machine with CE for Small Bevel Width

Qingdao Toyo Industry Co., Ltd.- Type:Bench Grinder

- Power Source:Electricity

- Object:Milling Cutter

- Application:Glass

- Disc(Wheel) Type:Grinding Disc

- Material:Metal

Base Info

- Model NO.:TYJT-G7,TYJT-G8

- Working Style:High-speed universal

- Power:13kw

- Minimum Processing Size:40*40mm

- Maximum Processing Size:2000*2000 mm with Extension Table

- Speed:0-4m,Min

- Voltage:380V, 50Hz, 3 Phrase,220V, 60Hz

- Certification:CE

- Structure:Horizontal

- Glass Edging Machine Type:Glass Beveling Machine

- Grinding Head Number:8

- Condition:New

- Control System:Manually

- Glass Washing Machine Type:N,a

- Transport Package:Container

- Specification:3400*1000*1730mm

- Trademark:TOYOCC

- Origin:China

- HS Code:8464201000

- Production Capacity:10000pieces,Year

Description

Horizontal Beveling MachineTechnical Parameters TYJT-G7 TYJT-G8 Dimensions 3400*1000*1730mm 3400*1000*1730mm Net Weight 1600kg 1700kg Glass Processing Thickness 3-8mm 3-8mm Angle 5-35-degree 5-35-degree Max Bevel Surface Width 20mm 20mm Mini Glass Size 40*40mm 40*40mm Max Glass Size 1600*1600 1600*1600 Max Glass Size with Extension Tables 2440*3000 2440*3000 Speed 0-4m/min 0-4m/min Voltage 380V, 50HZ, 3 Phrase

220V, 60HZ, 3 Phrase 380V, 50HZ, 3 Phrase

220V, 60HZ, 3 Phrase Power 13kw 13kw Number of the Motor Head 7 8

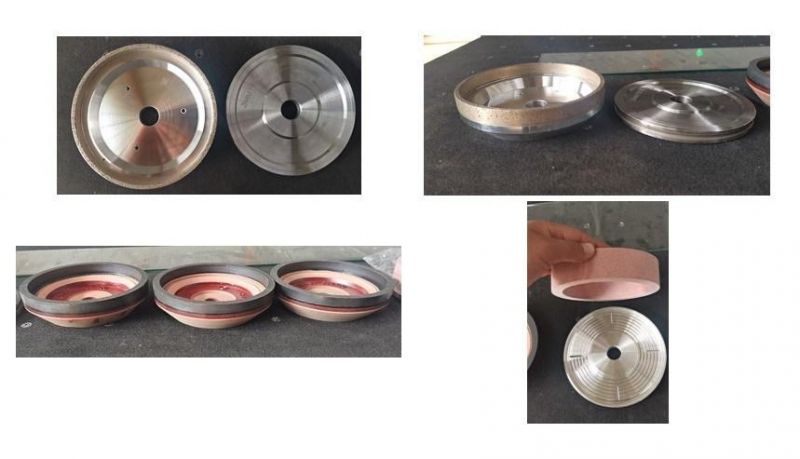

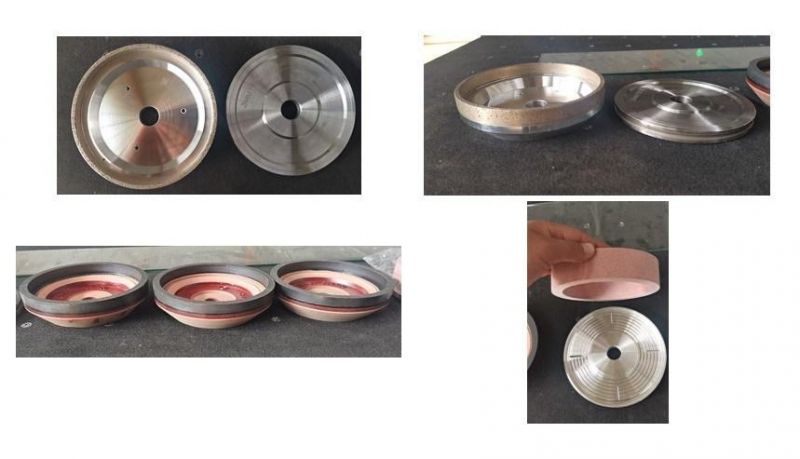

The layout of the wheels

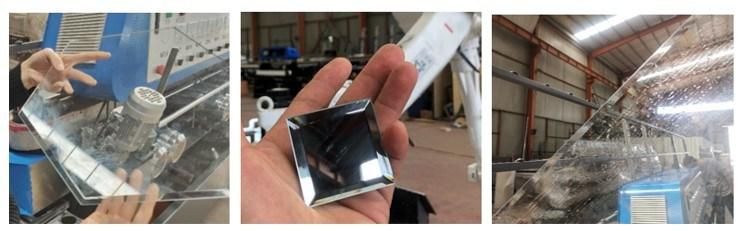

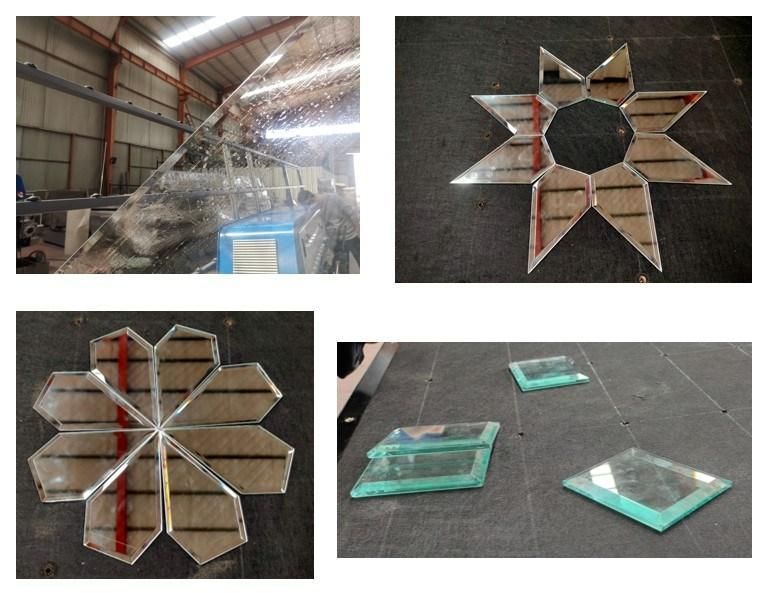

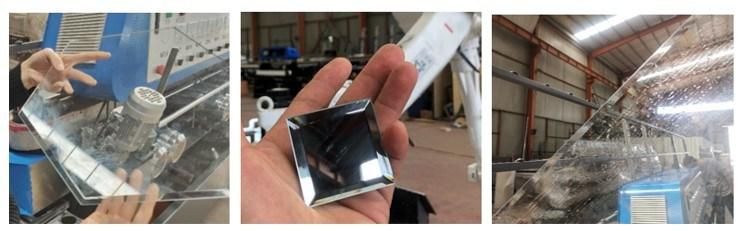

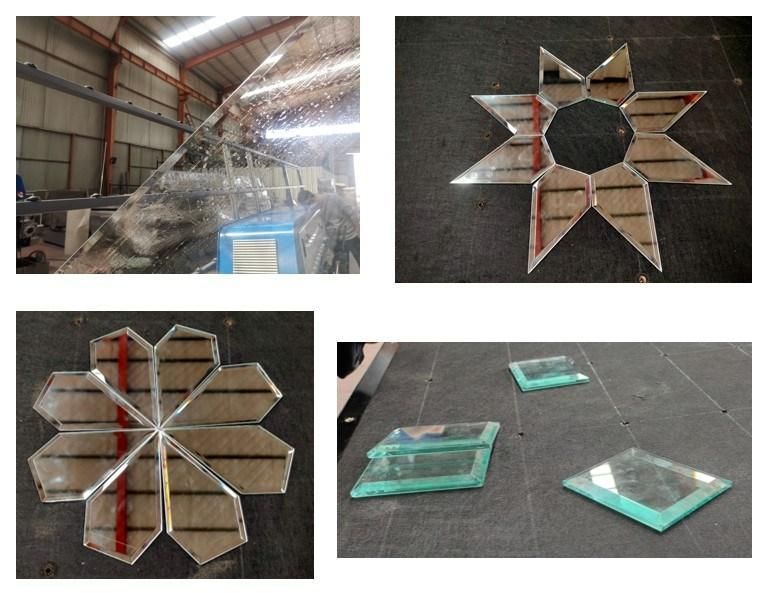

Machine Pictures

Daily Maintenance

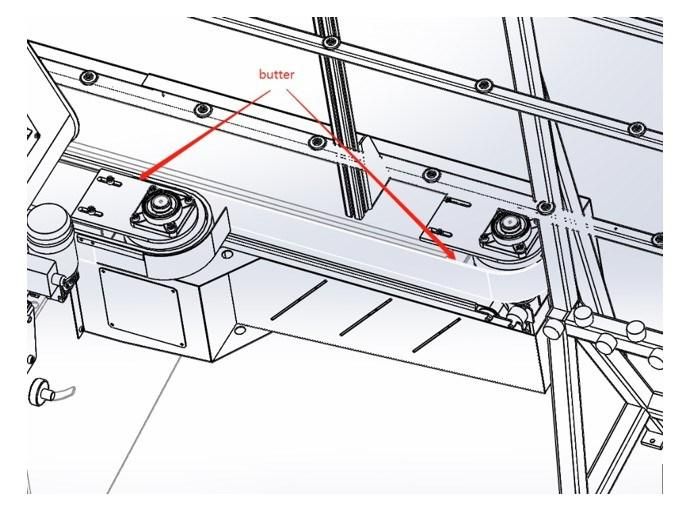

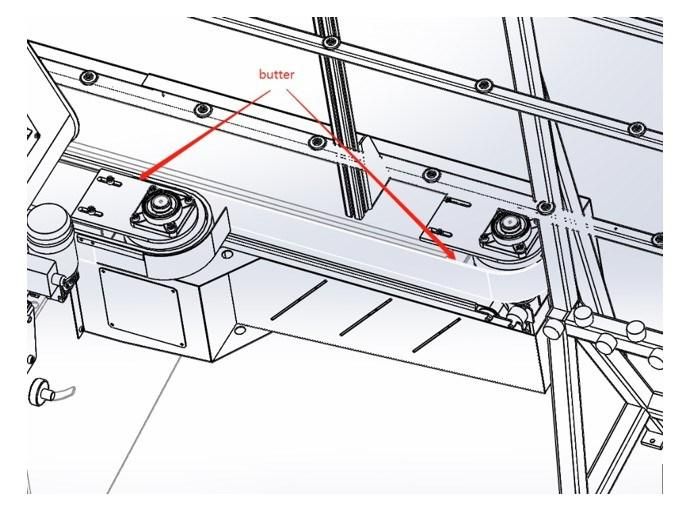

1. Holding the tooth surface of the back of the timing belt requires three times of lubricating grease, otherwise the normal service life of the machine will be affected due to the premature wear of the front and rear beam guide working surfaces. Each time you fill the lubricating grease, you must open the timing belt of the machine to the tooth surface. Just rotate the timing belt 2 turns.

2. When clamping the glass, the clamping force should be appropriate. Too loose will affect the grinding quality. Too tight will increase the load on the machine, which will cause jitter and crawling. It is also easy to crush the glass when thinning glass. The clamping force can be tested with a slightly larger glass clamp on the machine.That is to say: clamp the glass in the middle of the machine, and use both hands to move the glass when the machine is stopped, and feel that the clamping force is adjusted to just when both hands cannot move.

3. Note that after replacing the new grinding wheel, rotate the motor forward and backward handle clockwise to back out of the parallel grinding line to prevent the glass from damaging the grinding wheel.

4. It is recommended to replace the cerium oxide polishing coolant once a month. The polishing effect is not good due to wool generated during the polishing of the wool wheel.

CE Certification

Packing/Loading Pictures

220V, 60HZ, 3 Phrase

220V, 60HZ, 3 Phrase

The layout of the wheels

| Position 1 | Position 2 | Position 3 | Position 4 | Position 5 | Position 6 | Position 7 |

| Diamond Wheel | Diamond Wheel | Resin Wheel | Resin Wheel | Resin Wheel | Buffing Wheel | Buffing Wheel |

Machine Pictures

Daily Maintenance

1. Holding the tooth surface of the back of the timing belt requires three times of lubricating grease, otherwise the normal service life of the machine will be affected due to the premature wear of the front and rear beam guide working surfaces. Each time you fill the lubricating grease, you must open the timing belt of the machine to the tooth surface. Just rotate the timing belt 2 turns.

2. When clamping the glass, the clamping force should be appropriate. Too loose will affect the grinding quality. Too tight will increase the load on the machine, which will cause jitter and crawling. It is also easy to crush the glass when thinning glass. The clamping force can be tested with a slightly larger glass clamp on the machine.That is to say: clamp the glass in the middle of the machine, and use both hands to move the glass when the machine is stopped, and feel that the clamping force is adjusted to just when both hands cannot move.

3. Note that after replacing the new grinding wheel, rotate the motor forward and backward handle clockwise to back out of the parallel grinding line to prevent the glass from damaging the grinding wheel.

4. It is recommended to replace the cerium oxide polishing coolant once a month. The polishing effect is not good due to wool generated during the polishing of the wool wheel.

CE Certification

Packing/Loading Pictures