0.3~60mm Zirconia Alumina Composite Bead for Grinding Media.

Pingxiang Baitian New Materials Co., Ltd.- Materials:Zirconia Ceramic

- Function:Grinding

- Application:Chemical

- Certification:ISO, CE

- Performance:Stable

- Standard:Standard

Base Info

- Model NO.:BZA

- Chemical Component:Zro2 ≥90

- Bulk Density:3.2g,cm3

- Application 1:Ink.Paint.Coating. Pigment.Dyes Material

- Application 2:Electronic & Magnetic Material

- Application 3:TiO2 for Chemical Fibe,Ceramic Glaze

- Transport Package:25kg,Plastic Drum

- Trademark:Balltec

- Origin:Jiangxi, China

- Production Capacity:10000 Tons Per Year

Description

Basic Info.

Model NO. BZA Chemical Component Zro2 ≥90 Bulk Density 3.2g/cm3 Application 1 Ink.Paint.Coating. Pigment.Dyes Material Application 2 Electronic & Magnetic Material Application 3 TiO2 for Chemical Fibe,Ceramic Glaze Transport Package 25kg/Plastic Drum Trademark Balltec Origin Jiangxi, China Production Capacity 10000 Tons Per YearProduct Description

Packaging & Delivery

Selling Units:Single item

Single package size:

50X50X50 cm

Single gross weight:

0.125 kg

Package Type:

25kg/Plastic Drum

Lead Time:

| Quantity(Kilograms) | 1 - 3 | >3 |

| Est. Time(days) | 3 | To be negotiated |

BZA

Ball-tec® BZA is the most cost-effective ceramic grinding media , Made of modified zirconia powder

Feature & Application

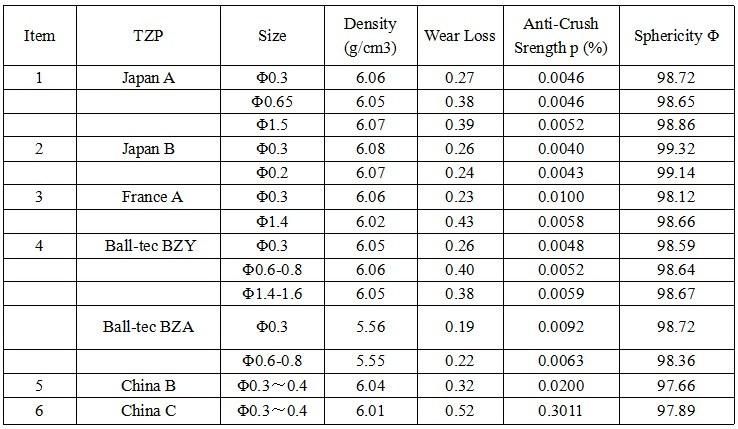

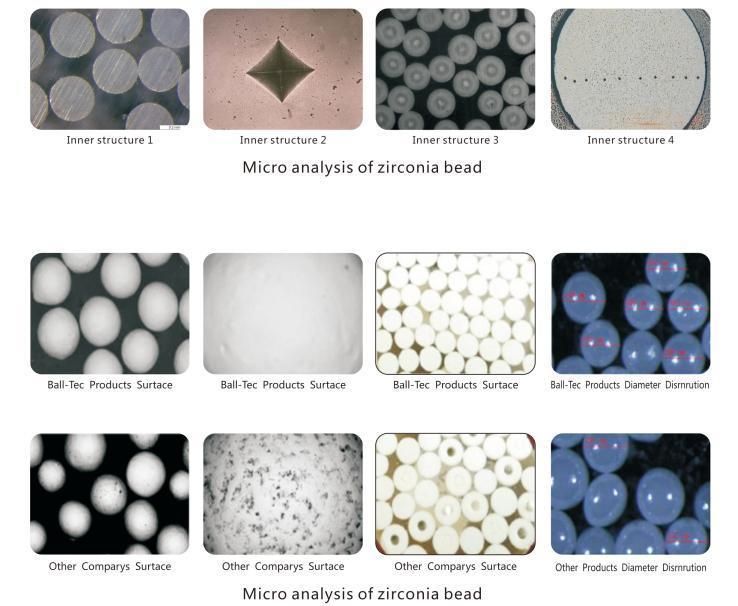

With special process, the internal structure of the beads is uniform and compact.

Good stability, strong acid &alkali resistance.

It keeps high grinding kinetic energy and reduces the amount of loading.

Smooth surface, easy clean, less wear to equipment.

It is suitable for grinding and dispersing all kinds of vertical, horizontal sand mill, ball mill and other equipment. It is the first choice that substitution performance to price ratio of yttria stabilized zirconia beads.

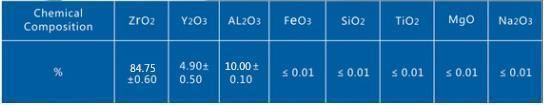

Chemical Composition

Physical Properties

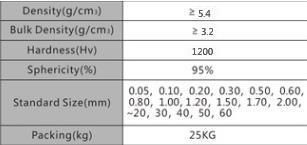

Comparation of Japan/France supplier's zirconia bead

Test Conditions:

Zirconia Bead :800g,Al2O3 Powder :200g,Water:400ml,After 6 hours in planetary mill. test the typical data.

Pingxiang Ball-tec New Materials Co., Ltd. is a number of well-known Ceramic enterprises work in Japan and Israel for many years technical experts and

domestic senior practitioners Co-founded high-tech enterprises with R&D, production and sales . Covers an area of 100,000 square meters, focusing on

zirconia /alumina micro crystalline ceramic grinding media, Bio-dental, solid fuel cells, 3D printing and other high purity zirconia powder. And It's the sole

agent of Israel RIMI zirconia beads, maintain long-term partnership relation with the Israel Ceramics Institute.

Since the beginning of 2000, Ball-tec has only one committed that supply nano technology ultra-fine solutions to high-tech industry .

Today, Ball-tec focus on zirconia series grinding media ,zirconium structure, zirconia powder series.

Our aim has never changed and we are committed to providing our customers with high-quality, multi-choice ultrafine grinding solutions.

Application

1.New Energy lithium battery: Lithium Iron Phosphate,Lithium titanate,Graphite,Silicon carbon,Graphene,Carbon Nanotube,Alumina ceramic diaphragm.

2.Digital Ink& Jet Ink: Thermal Transfer Ink,Solvent Ink,TC-S Ink,Textile Pigment Ink,Digital printing disperse dye ink,Pigment Ink,LED-UV Curing Ink,Coating Ink,Printing Ink,Pen Ink.

3.Paints&Inks&Dyes:Automobile paint,Carpentry paint,Anticorrosion paint,resin,Offset printing ink,UV Ink,Intaglio Ink,Water-based Ink,Water-soluble varnish,UV varnish,Disperse Dyes,Fluorescent Dyes,Metal PigmentS,Titanium Dioxid.

4.Ceramic Ink&Glaze:Ceramic Ink,Glass Pigment,Ceramic Glaze Stains,Occlusion Pigment,Low melting glaze pigment,High melting glaze pigment,Metallic luster pigment.

5.Electronic&Magnetic:Soft Magnetic Materials,Permanent Magnetic Materials,Conductive Ink,Silver Paste,Rare Earth Metal,Target Material,Graphene Conductive Agent,Electronic Insulators Materials,Piezoelectric Materials,Ceramic Capacitor Materials

6.Agricultural Chemicals:Agrochemical Suspension Agent

7.Food:Chocolate Grinding

8.Cosmetics&Medicine:Cream Cosmetics,Nano Pharmaceutical Powder

9.Paper Making: Grinding heavy calcium carbonate

10.Mines:Gold Mine,Rare Earth Metal Ore,Lithium Ore,Inorganic nonmetallic Ore,Titanium ore