Silicate Zirconium Balls CS-40 as Ceramic Grinding Media for Ball Mill

Pingxiang Chemshun Ceramics Co., Ltd.- Material:Zro2, Sio2

- Usage:Construction, Machinery, Grind

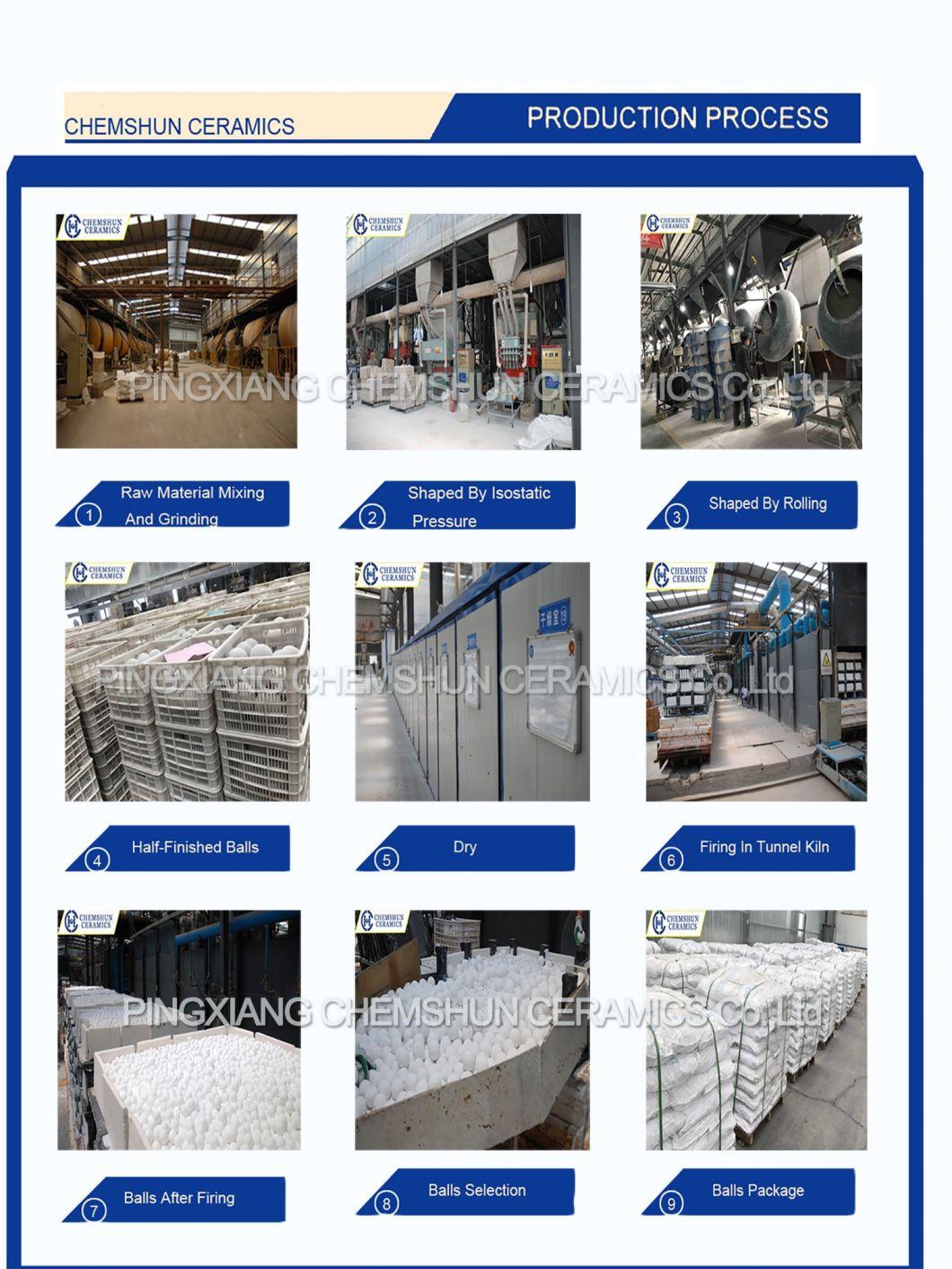

- Processing Type:Rolling or Isostatic Pressing

- Size:0.4~5mm

- Color:Cream

- Customized:Customized

Base Info

- Featrue:High Hardness, High Density and Anticorrosion

- Application:Mining Machine

- Grinding Situation:Dry Grinding, Wet Griding

- Field:Cement, Chemical, Paints, Inks, Dyes

- OEM:Accept

- Specific Gravity:4.0~4.2g,cm3

- Vickers Hardness:1000~1050

- Water Absorption:0%

- Application Industry:Ceramics, Minerals, Ores

- Transport Package:by Bags, Then Fasten on Pallet.

- Specification:D0.4~D5mm

- Trademark:Pingxiang Chemshun Ceramics

- Origin:P. R. China

- HS Code:69091200

- Production Capacity:10000 Ton , Year

Description

Basic Info.

Featrue High Hardness, High Density and Anticorrosion Application Mining Machine Grinding Situation Dry Grinding, Wet Griding Field Cement, Chemical, Paints, Inks, Dyes OEM Accept Specific Gravity 4.0~4.2g/cm3 Vickers Hardness 1000~1050 Water Absorption 0% Application Industry Ceramics, Minerals, Ores Transport Package by Bags, Then Fasten on Pallet. Specification D0.4~D5mm Trademark Pingxiang Chemshun Ceramics Origin P. R. China HS Code 69091200 Production Capacity 10000 Ton / YearProduct Description

Silicate zirconium balls CS-40 as ceramic grinding media for ball millDescription:

CS-40 series Zirconia Silicate ceramic grinding media is an ultra high-performance, middle density, durable and cost effective ceramic grinding media, applications in stirred vertical mills and horizontal mills such as Metso's SMD , Glecore IsaMill, FLSmidth's VXP mill or the Outotec HIGMill. With superior strength, high hardness, wear resistance and consistent particle size and shape characteristics, It is well suited to high speed milling process of mineral ores and similar hardness and provide unmatched economic and performance for you.

Appearance

Technical data:

Chemical and physical properties

| Property | Data |

| Main chemical composition | ZrO2, SiO2, Al2O3 |

| Diameter range | 0.4~5mm |

| Specific gravity | 4.0~4.2g/cm3 |

| Roundness | >93% |

| Vickers hardness | 1000~1050 |

| Water absorption | 0% |

| Color | Cream |

Note: The data of the sheet here are based on laboratory testing, data is subject to change due to continuous improvement of the products.

The Benefits:

>High grinding efficiency

>Decreasing product contamination

>Longer product life cycle

>Reduce mill wear and maintenance cost, less down time

>Less energy than steel or iron balls

>Less cost per volume than high-density steel media alternatives

The Features:

>High hardness

>Superior impact and wear resistance

>Uniform size and good roundness

>Inert Chemical and environmentally friendly

>Engineered made

Applications:

>Mining

>Mineral

>Industrial Ceramics

>Electronic Ceramics

>Cement

>Chemical

>Paints

>Inks

>Dyes

>Pigments

>Magnetic coatings

Package:

1ton big-bag, or 25kg/small bag, or 25kg/drum.

Service:

We have experts team understand your needs supply the engineered great ceramic grinding media for your grinding application.

We offer on-site visiting, lab testing, professional solution for you.

Web:chemshun.en.made-in-china.com .

Export:

Our products have been exported to many countries: Australia, Chile, USA, Russia, UK, Indonesia, etc., good quality have be approved by our clients.