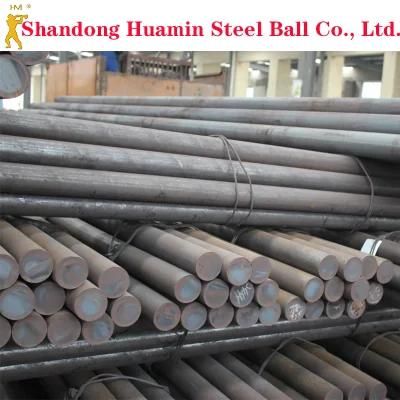

Grinding Steel Rod Wear Rod Used in Smelter Chemical Plant

Shandong Huamin Steel Ball Joint-stock Co., Ltd.- Materials:304

- Certification:ISO, GS

- Applications:Oil

- Shape:Round

- Specifications:20

- Standard:Standard

Base Info

- Model NO.:50-80

- Transport Package:Maritime Transport

- Specification:1000kg

- Trademark:huamin

- Origin:China

- HS Code:7228600

- Production Capacity:50000ton,Year

Description

Our company is founded in 1986, which is about 31 years in the fields of production of the Grinding media (Grinding Steel Balls, Grinding Steel Rods), now it is one of the largest manufacturers and exporters of Grinding Media in China. The production capacity is 150, 000 Metric Tons per year, the products is produced by the Automatic Rolling forged Equipment, which is the world-advanced facilities with the high efficiency and high assurance of the quality!,!

Our company is founded in 1986, which is about 31 years in the fields of production of the Grinding media (Grinding Steel Balls, Grinding Steel Rods), now it is one of the largest manufacturers and exporters of Grinding Media in China. The production capacity is 150, 000 Metric Tons per year, the products is produced by the Automatic Rolling forged Equipment, which is the world-advanced facilities with the high efficiency and high assurance of the quality!,!The company has been the world-wide leader for its patented automatic rotary rolling steel ball production line and patented automatic steel grinding rod production line. At present, four invention patents and ten utility model patents are possessed by the company.

Concentrating on wear-resistant grinding material for 31 years, Shandong Huamin Steel Ball Joint-Stock Co., Ltd is one of the largest grinding rod manufactures in China. We manufacture the product with the length of and the diameter of .

a. The blanking of the steel grinding rod is implemented via the sawing machine. The dimensional tolerance would abide by the requirement of the order. After the implementation of blanking, the two ends of the raw material are polished into the R arc via the polishing machine.

a. The blanking of the steel grinding rod is implemented via the sawing machine. The dimensional tolerance would abide by the requirement of the order. After the implementation of blanking, the two ends of the raw material are polished into the R arc via the polishing machine.b. The surface of the product for the rod mill cannot have the crack, overburning and fissure visible to the naked eyes.

c. The nonstraightness of the product is less than 0.2%. The diameter tolerance ranges from +0mm to -1.5mm. The length tolerance is from +0mm-25mm. The fracture should be less than 3%.

The steel grinding rod is the optimum choice for the enterprises using the rod mill and the coal mill, such as cement plant, electric power plant, mine, quartz sand plant, silica sand plant, sand aerated industry, coal chemical industry, gas concrete plant, etc.

We pack our products by wooden box or bundled.Currently, most of the enterprises utilize the round bar steel rolled by the steel mill as the steel grinding rod directly. The round bar steel has very low hardness of only 12HRC to 25HRC, and the internal stress, leading to broken damage easily and low wear resistance property. Meanwhile, the round bar steel comes with some defects such as loose and not compact internal structure. Just because of that, using the round bar steel for grinding would cause a series of problems such as large wear, easily bending, breaking, winding, two tapering ends, low productivity, failing to reach the expected qualified rate, heavy workload of the follow-up magnetic separation process, etc.

We always insist on "High-quality Product, Competitive Price, Timely Delivery and Satisfied Service".