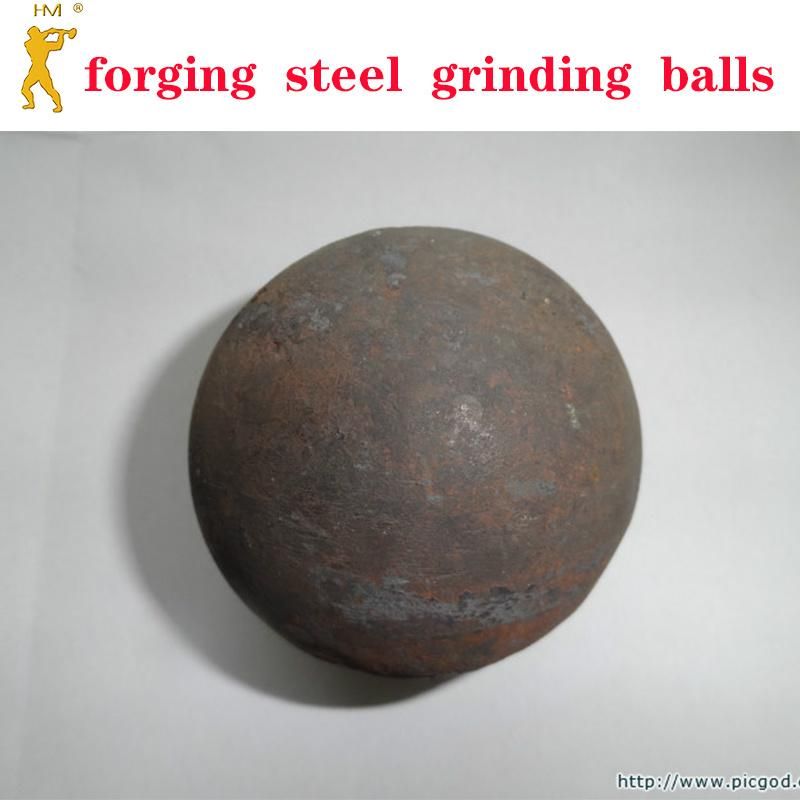

Wear-Resistant Ball with Good Mechanical Properties and Low Impact Crushing Rate

Shandong Huamin Steel Ball Joint-stock Co., Ltd.- Material:Stainless Steel

- Content:>90%

- Usage:Construction, Machinery, Chemical

- Processing Type:Rolling Type

- Size:Big

- Color:Black

Base Info

- Model NO.:20-150

- Customized:Customized

- Specification:1000kg

- Trademark:huamin

- Origin:China

- HS Code:7326110000

- Production Capacity:100000ton,Year

Description

Application fields: forging balls for mills in various metal mines (gold, copper, iron, silver, manganese, etc.), forging steel balls for cement mills, forging steel balls for power plants, forging steel for coal (phosphorus) chemical industry Selection of forged steel balls for grinding balls, steel slag, and forged steel balls for quartz sand.

Product application: Air hammer forged steel balls are produced by air hammer forging, first forging and then quenching. They are suitable for wet grinding ball mills and semi-autogenous mills. Depending on the material and hardness, the performance is different. The equipment is simple and the investment cost is low. The key lies in the forging level of the workers. The steel balls forged by workers of different levels will be affected in terms of roundness, compactness, hardness uniformity, etc. make a difference.

Applications:

Air hammer forged steel balls are produced by air hammer forging, first forging and then quenching. They are suitable for wet grinding ball mills and semi-autogenous mills. Depending on the material and hardness, the performance is different. The equipment is simple and the investment cost is low. The key lies in the forging level of the workers. The steel balls forged by workers of different levels will be affected in terms of roundness, compactness, hardness uniformity, etc. make a difference.

Product process:

Product process:Raw material: high quality round steel cutting material

Forming: air hammer forging

Quenching: quenching fluid

Tempering: Continuous Tempering Furnace

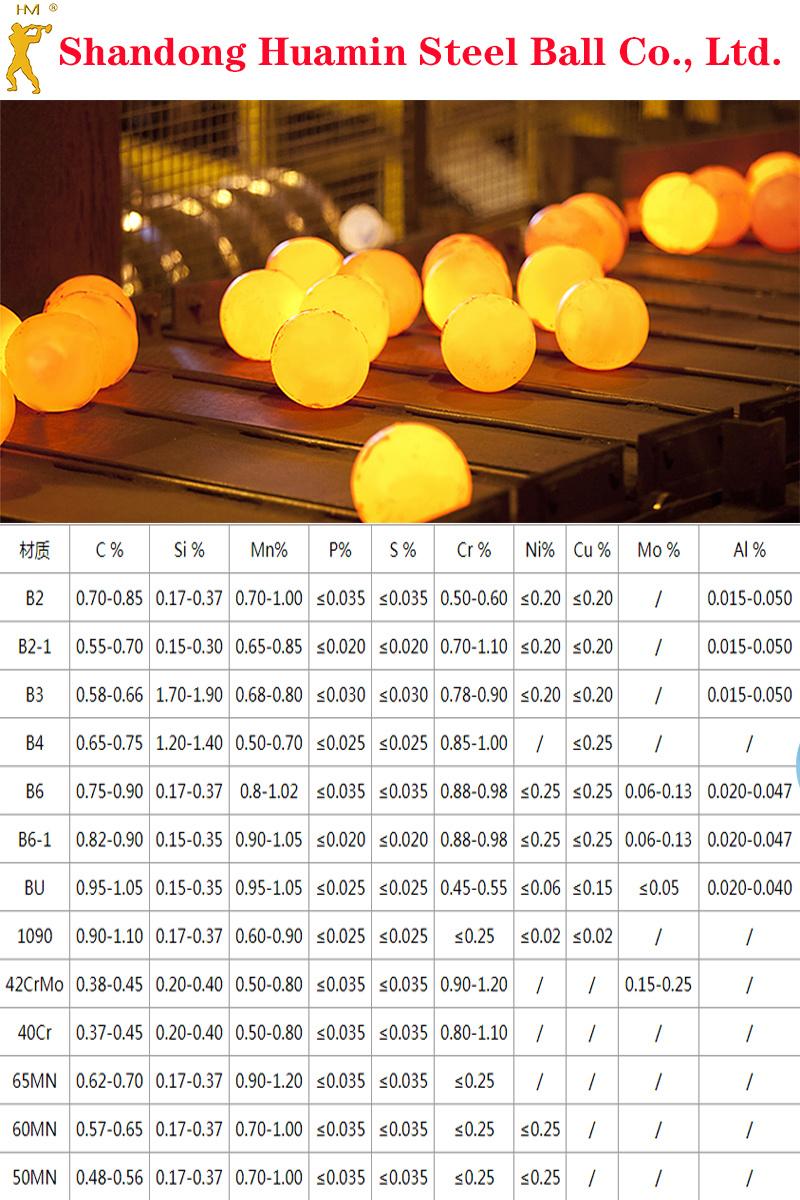

technical parameter:

Hardness: HRC55-65

Impact toughness: ≥12 joules

Drop times: ≥20000 times

Density: 7.9g/cm3

Working temperature: within 80ºC

Product features and compliance certification:

1. Good mechanical properties, impact resistance, low crushing rate

2. High hardness and wear resistanceProduction according to ISO9001 quality system