Mining Zirconium Oxide Beads as Micro Milling Media

Pingxiang Chemshun Ceramics Co., Ltd.- Material:Zirconia

- Content:78~80%

- Usage:Grind

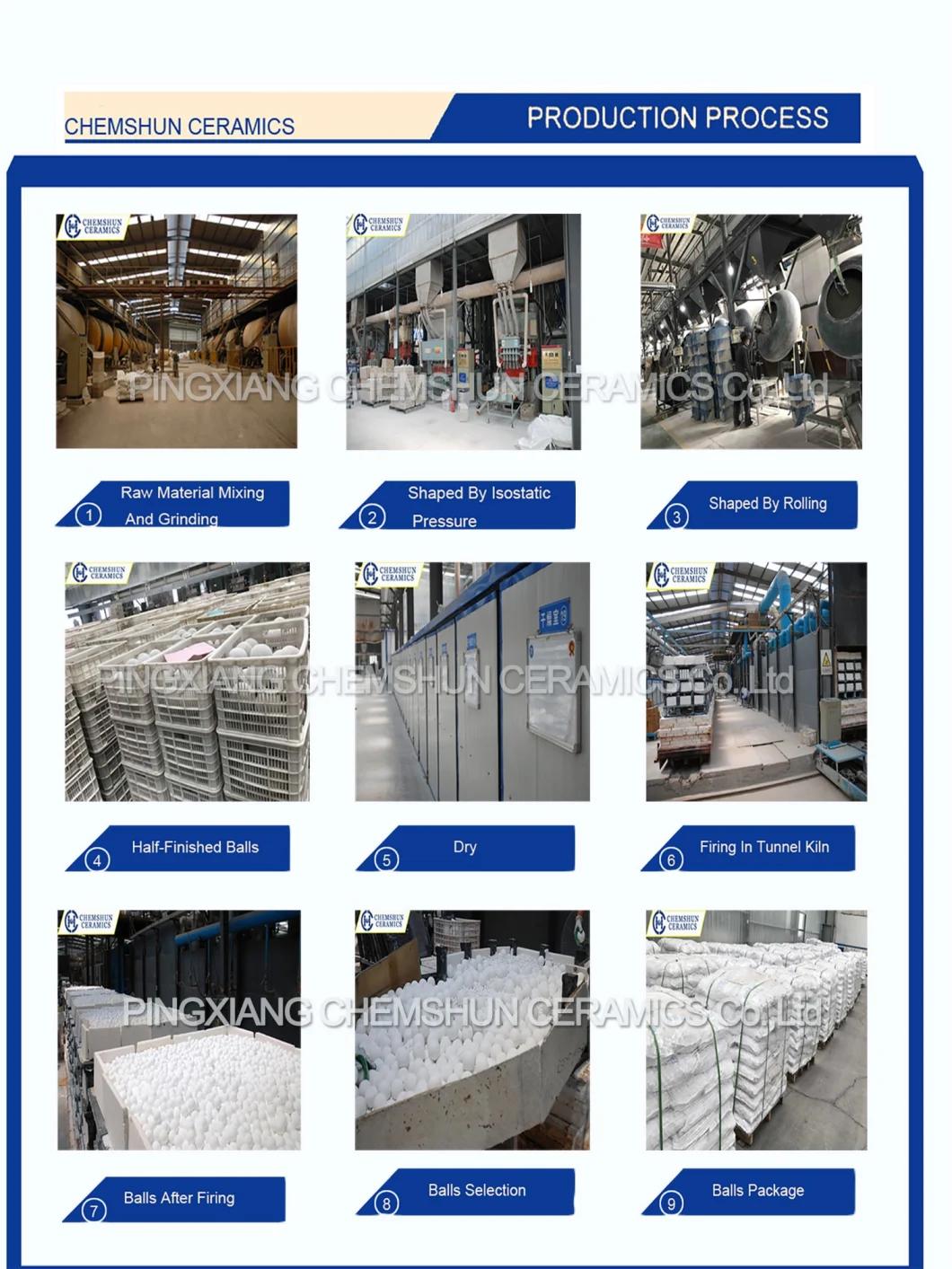

- Processing Type:Isostatic Pressing Type

- Size:Small

- Color:White

Base Info

- Model NO.:chemshun ceramics

- Customized:Customized

- Item:Zirconia Grinding Balls

- Materials:Zirconia and CEO2

- Type:High-Zironia

- Diameter:1mm-70mm

- Grinding Situation:Dry Grinding , Wet Griding

- Feature:High Hardness, High Density and Anticorrosion

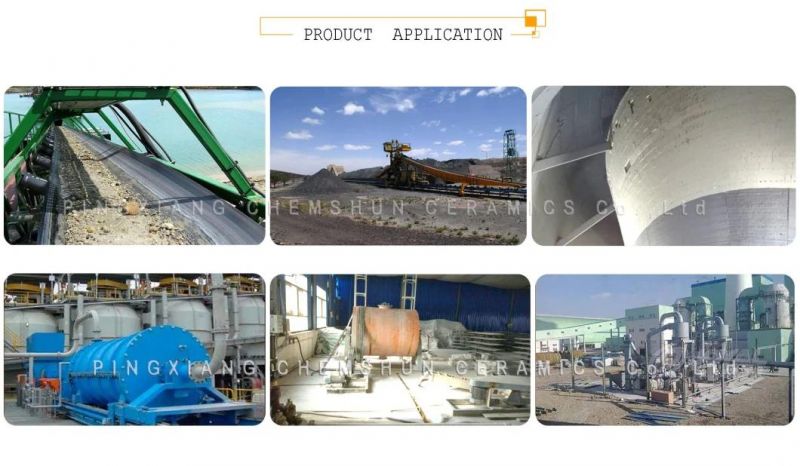

- Application:Ball Mill, Pebble Mill ,

- Field:Ceramic,Metallurgy, Glass, Porcelain, Enamel

- OEM:Accept

- Transport Package:by Bags, Then Fasten on Pallet.

- Specification:D1~D70mm

- Trademark:pingxiang chemshun ceramics

- Origin:P. R. China

- HS Code:69091200

- Production Capacity:10000ton,Year

Description

Basic Info.

Model NO. chemshun ceramics Customized Customized Item Zirconia Grinding Balls Materials Zirconia and CEO2 Type High-Zironia Diameter 1mm-70mm Grinding Situation Dry Grinding , Wet Griding Feature High Hardness, High Density and Anticorrosion Application Ball Mill, Pebble Mill , Field Ceramic,Metallurgy, Glass, Porcelain, Enamel OEM Accept Transport Package by Bags, Then Fasten on Pallet. Specification D1~D70mm Trademark pingxiang chemshun ceramics Origin P. R. China HS Code 69091200 Production Capacity 10000ton/YearProduct Description

Mining Zirconium Oxide Beads As Micro Milling MediaDescription:

With the properties of naver aging and never broken , Chemshun Ce-TZP zirconia media has a very long uselife , and it's abrasion is smallest of all zirconia media with excellent wear -resistance performance , so it is widely used in grinding and the factories of inks , paer, paints, metal and non-metallic minerals etc.

Appearance:

Technical data :

| Properties | Unit | Data |

| Composition | Wt% | 78~80% ZrO2 20~22% CeO2 |

| Bulk Density | Kg/L | 3.8(Ф7) |

| Specific Density | G/cm3 | ≥6.2 |

| Moh's Hardness | Grade | ≥9 |

| Vickers Hardness | HV | ≥1100 |

| Elastic Modulus | Gpa | 200 |

| Thermal Conductivity | W/m,k | 3 |

| Fracture Toughness | Mpam1/2 | ≥8.5 |

| Grain Sizes | µm | <=0.5 |

| Thermal Expansion Coefficient (20~400 ºC) | 10*10-6/ºC (20-400) | 9 |