240L Fully Automatic Centrifugal Disc Finishing Machine

HUZHOU INOVATEC MACHINERY CO., LTD.- Type:Vibratory Grinding Machine

- Power Source:Electricity

- Object:Parts

- Application:Metal Deburring Polishing

- Disc(Wheel) Type:Round

- Material:Iron,PU

Base Info

- Model NO.:CD

- Working Style:Shaking

- Disc Diameter:Customer

- Variable Speed:With Variable Speed

- Transport Package:Wooden Box

- Specification:20L

- Trademark:Inovatec

- Origin:Huzhou, China

- HS Code:84639000

- Production Capacity:3000

Description

Basic Info.

Model NO. CD Working Style Shaking Disc Diameter Customer Variable Speed With Variable Speed Transport Package Wooden Box Specification 20L Trademark Inovatec Origin Huzhou, China HS Code 84639000 Production Capacity 3000Product Description

240L Fully automatic Centrifugal disc finishing machine

Catalog Download

https://inovatecmachinery.en.made-in-china.com/Product-Catalogs/

Centrifugal Disc Tumbler Product Description:

CD automatic centrifugal disc tumbler machine offers an automatic solution for big batch processing for smaller parts. The high energy disc finishing technology provides up to 10-30 times faster process than vibratory finishing. The short processing time and high automation level is a major advantage of the finishing process.

At INOVATEC, 120L and 230L are the most popular size centrifugal disc finisher. Depending on spinner speed (50-180 RPM) and the water level, centrifugal disc finishing equipment can accomplish work from aggressive deburring to luster polishing.

Typical application includes pre-painting finishing, Belt buckle deburring, Pre-plating finishing, finishing before coating.

Centrifugal Disc Tumbler Feature:

- Compact design and easy to handle

- Process timer setting

- Continuous speed adjustment

- Optional processing barrel unloading and discharge

- Optional forward and backward movement

- Automatic media and parts discharge

- Media and parts separation sieve integrated

Centrifugal Disc Tumbler Application:

- Stampings, castings or machined parts finishing

- Parts with size around 150mm or smaller

- Parts with thickness 1mm and above

Centrifugal Disc Tumbler Technical Data:

| Centrifugal Disc Tumbler | Capacity | Size L×W×H(mm) | Motor (kw) | Weight (kg) | Speed (rpm) | Chamber dimension | PU thickness (mm) |

| CD50B | 50 | 1010×660×1220 | 1.5 | 350 | 50-180 | 460 | 22 |

| CD120B | 120 | 1700×1380×1410 | 4 | 1100 | 0-160 | 640 | 26 |

| CD230B | 230 | 2450×1700×2000 | 7.5 | 2000 | 0-140 | 800 | 30 |

Centrifugal Disc Tumbler Product Details:

Water discharge system:

Centrifugal Disc Tumbler Dosing Pump:

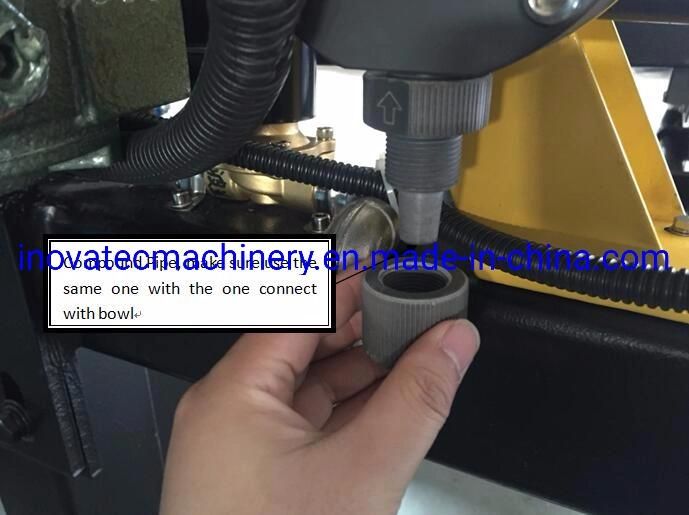

Centrifugal Disc Tumbler Important:

- Make sure you need to run machine with water inside and cover gap between disc and barrel. Dry running will destroy disc and barrel

- If process time more than 2 hours, you need discharge water because water is too hot. Then you change new water to process

- When media size bellow 4mm, DO NOT use in centrifugal disc finishing machine otherwise it will stuck into the gap

- Check the gap between disc and barrel every day, 0.5-0.7mm is the right size. If too large or too small, please make the adjustment

Metal Surface deburring and finishing Company introduction:

Vibratory Finishing Equipment Optional settings:

Vibratory Finishing and Polishing Successful Project:

Parts before and after vibratory polishing, vibratory deburring, cleaning, edge rounding, descaling, degreasing, de-oiling, cleaning, edge breaking,radiusing:

Mass Finishing Equipment and Grinding media Packing and shipment:

Payment:

FAQ:

Q: How is Inovatec machinery brand?

Inovatec Machinery is famous Top 3 brand mass finishing equipment and consumables manufacturer of China, has:

- 25 years: vibratory finishing machines and tumbling media manufacturer experience.

- 20000 square meters factory

-2 year warranty

Q: What Certifications do you have?

ISO9001, CE, certifications etc. 100% quality check, and testing before shipment.

Q: What is Inovatec Machinery equipment warranty?

2 year warranty for all Inovatec Machinery equipment

Lifetime maintenance will be provided after the 2 year warranty period expires.

Q: How you guarantee tumbling media quality?

We make quality tracking from raw material until quality check before shipment. We keep record of quality test including wearing and cutting.

For bulk and OEM order, we follow your testing methods and keep track of wearing and cutting. If the quality does not meet the standard, we will not make the shipment.

Q: What is your Payment method?

Accept payment via T/T (Bank transfer), Western Union, Money Gram, and PayPal;

Accept L/C at sight (bulk order).

Q: What is your Minimum order amount?

For machine minimum order is 1 PCS. For tumbling media minimum order is 1000kg or 2000 lbs as one pallet.

You can ship less amount of media if ship with the machine.

Sample order is allowed to ship less amount of tumbling media

Q: What is your way of packaging?

Fermentation wooden pallets for media, 1000kg per pallet, 25kg/plastic bag

Customize packaging and logo printing is available for discuss

Wooden box for equipment and compound

Q: How long is your production time?

15 working days for sample order;

20-25 working days for bulk order.

Emergency order can be fulfilled in a week

Q: What is the Shipping Way?

20-30 days by sea to your nearest seaport

2-5 days by air to your nearest airport

3-5 days by express to your doorstep

Q: What is the nearest Port:?

Shanghai, Ningbo and Yiwu are the closest port.

Contact us: