100L Horizontal Bead Mill Machine for Paint Production

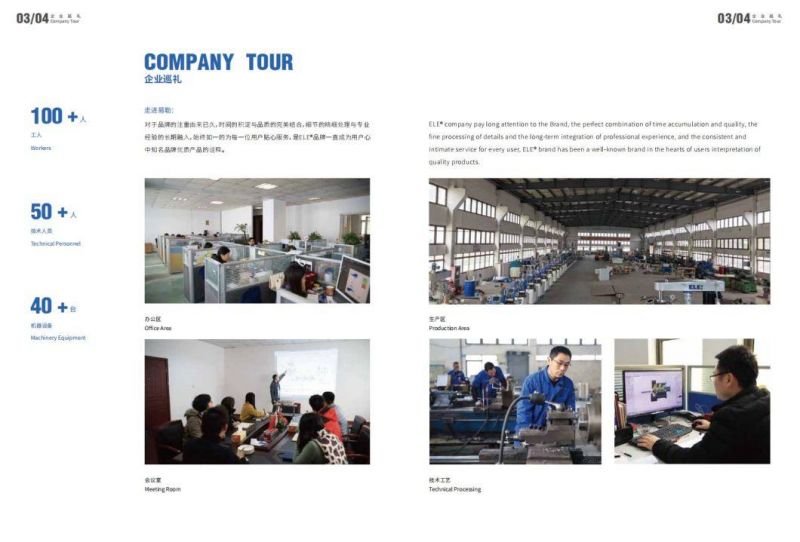

Shanghai ELE Mechanical & Electrical Equipment Co., Ltd.- Type:Mill

- Material:Zirconia, Stainless Steel

- Function:Wet Grinding, Milling

- Grinding Medium:Zirconia Beads

- Applicable Industry:Coating, Paint, Ink, Pigment, Latex

- Materials:Stainless Steel or Pure Zirconia

Base Info

- Model NO.:EDW-50

- Usage:Industrial

- Product Type:Paint

- Transport Package:Wooden Case

- Specification:EDW-5L----EDW-100L

- Trademark:ELE

- Origin:Shanghai, China

- HS Code:8479820090

- Production Capacity:200-2000L

Description

Basic Info.

Model NO. EDW-50 Usage Industrial Product Type Paint Transport Package Wooden Case Specification EDW-5L----EDW-100L Trademark ELE Origin Shanghai, China HS Code 8479820090 Production Capacity 200-2000LProduct Description

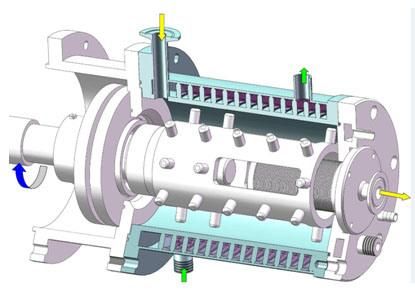

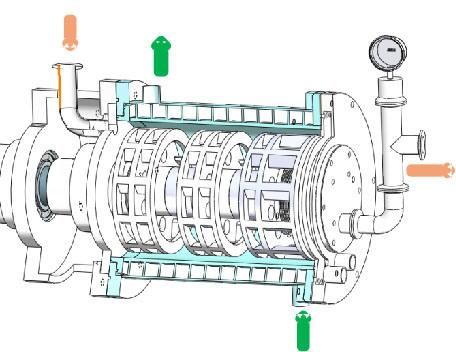

Horizontal Bead Mill (EDW)

Applications:

Middle, Low, High viscosity raw material, suitable for super fineness required Paints and printing inks, high quality car paint, pigments and dyes, ...A high abrasion nanoscale bead mill.

Three Types

Pin type

Turbo type

Disc Type

Features:

1. High abrasive resistance: Materials (zirconia, tungsten carbide, hard alloy etc. ) guarantee working life.

2. Dynamic fence booms: Discharge solve problems of slow discharge and grinding medium getting stuck.

3. German BURGMANN double mechanical end face seal, which can bear more than 10bar pressure.

4. Corrugated cooling system increase cooling area and improve cooling efficiency.

5. Grinding beads small to 0.2mm guarantee superfine grinding/milling.

6. Meet demands of continuous production&different viscosity& fineness.

7. Inner & outer double pins improve high wet grinding/milling efficiency.

8. Ex-proof (optional) & fault alarming.

| Model | Chamber Volume (ml) | Main Power (kw) | Rotation Speed (rpm) | Capacity (L/h) | Dimension L*W*H (mm) | Weight (kg) |

| EDW-5 | 5 | 7.5 | 1440 | 200 | 1300*1050*450 | 650 |

| EDW-15 | 15 | 18.5 | 1440 | 500 | 1600*1450*650 | 1200 |

| EDW-20 | 20 | 22 | 1260 | 800 | 1600*1450*650 | 1350 |

| EDW-30 | 30 | 37 | 1260 | 1200 | 1650*1550*750 | 1700 |

| EDW-40 | 40 | 45 | 980 | 1500 | 1750*1650*850 | 2100 |

| EDW-50 | 50 | 55 | 980 | 2000 | 1900*1850*850 | 2300 |

| EDW-100 | 100 | 110 | 860 | 3000 | 2300*2150*950 | 3800 |

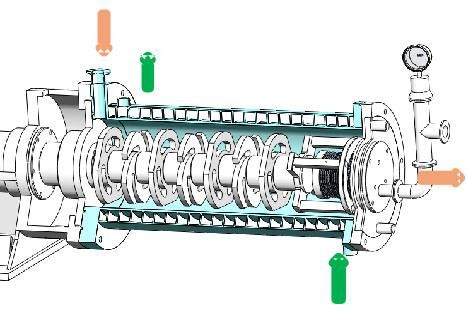

The differencePin Type Bead Mill:

High efficiency ,good performance, Nanometer grinding, Narrow distributor; Suitable for different viscosity material: Low, Middle and High Turbo Type Bead Mill:

Higher efficiency ,better performance, Nanometer grinding, Narrow distributor; Suitable for different viscosity material: Low, Middle and High Disc Type Bead Mill:

Low cost, Economic, Suitable for NOT Fine particle size requested,

Low & Middle viscosity material

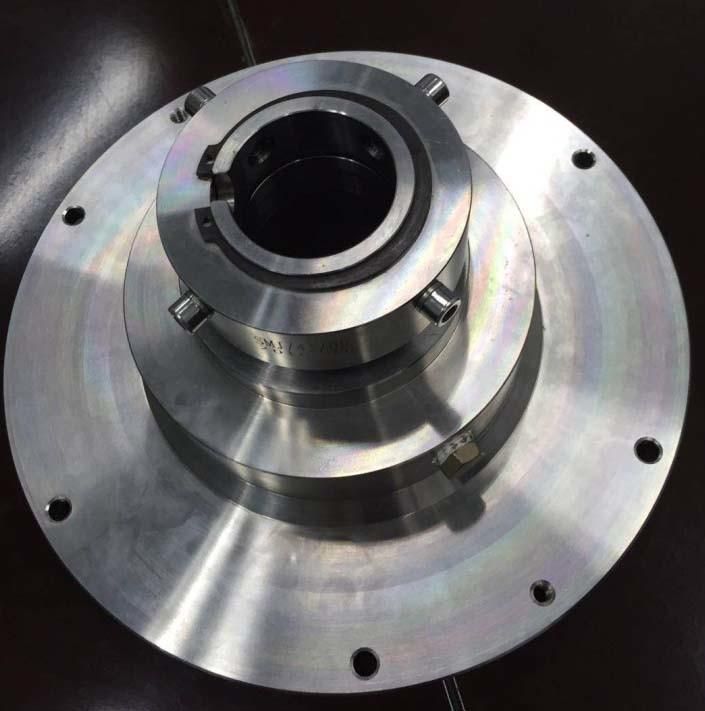

Mechanical Seal:

Key part of bead mill, ELE adopt Big Flange double cartridge Mechanical Seal, Burgmann technology, Can endure 8-10Kg Pressure;

High precision, good sealing performance, Longer service time;

A whole part, easy for installation and maintenance

With Cooling liquid level sensor and pressure sensor.

Connections end, we adopt one end clamp, NOT two ends clamps no assembling run-out tolerance

Key parts & Brand

| NO. | Parts | Brand |

| 1 | Main Motor | Shanghai Motor Brand |

| 2 | Mechanical Seal | Burgmann technology |

| 3 | Rotor | YM Harden Alloy Steel/ Ceramic |

| 4 | Electrical | Schneider |

| 5 | Inverter | ZONCN |

| 6 | Belt Pulley | Mitsu Belt, OVITO Pulley |

| 7 | Temperature meter & pressure meter | Electrical contact quakeproof |

| 8 | Feeding Pump | ARO Ingersoll Rand Diaphragm pump |