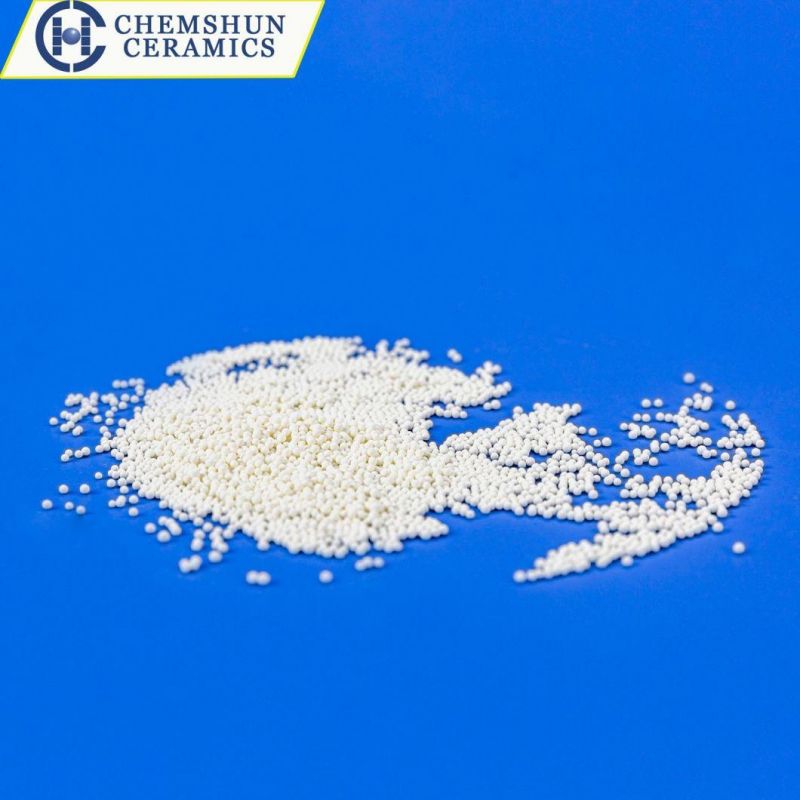

92% Alumina Ceramic Ball for Wet Grinding

Pingxiang Chemshun Ceramics Co., Ltd.- Material:Ceramics

- Content:>90%

- Usage:Grind

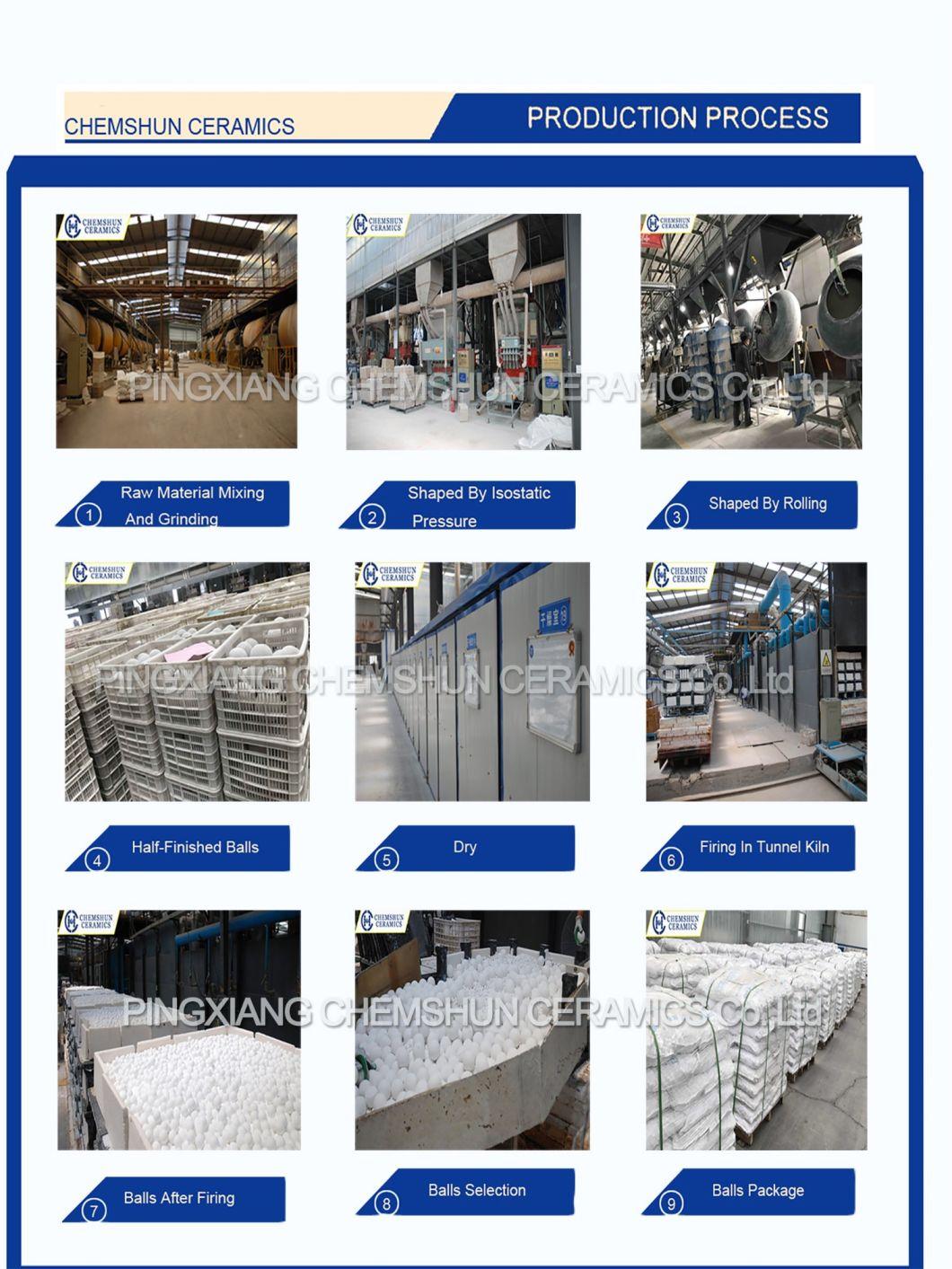

- Processing Type:Rolling Type

- Size:Big

- Color:White

Base Info

- Model NO.:chemshun ceramic balls

- Customized:Customized

- Item:Ceramic Ball

- Materials:Alumina

- Alumina Content:68% 90% 95%

- Type:High-Alumina

- Feature:High Hardness,High Density

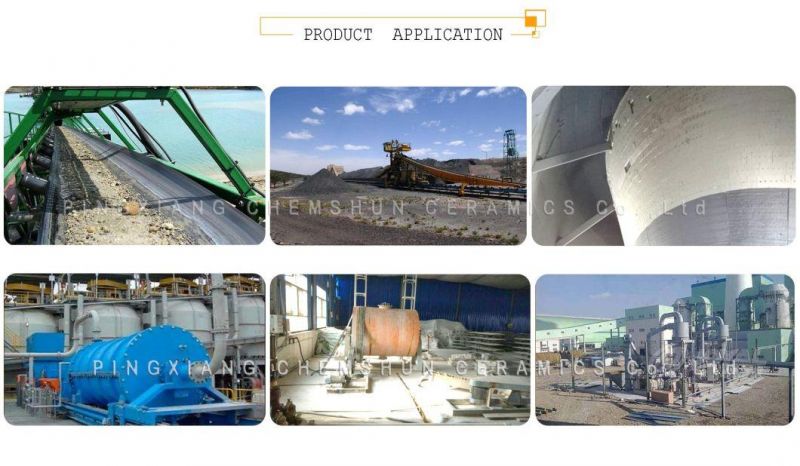

- Application:Ball Mill, Pot Mill, Librating Mill

- Field:Ceramic,Metallurgy, Glass, Porcelain, Enamel

- OEM:Accept

- Transport Package:by Bags, Then Fasten on Pallet

- Specification:D3-70mm

- Trademark:pingxiang chemshun ceramics

- Origin:China

- HS Code:69091200

- Production Capacity:10000ton Per Year

Description

Basic Info.

Model NO. chemshun ceramic balls Customized Customized Item Ceramic Ball Materials Alumina Alumina Content 68% 90% 95% Type High-Alumina Feature High Hardness,High Density Application Ball Mill, Pot Mill, Librating Mill Field Ceramic,Metallurgy, Glass, Porcelain, Enamel OEM Accept Transport Package by Bags, Then Fasten on Pallet Specification D3-70mm Trademark pingxiang chemshun ceramics Origin China HS Code 69091200 Production Capacity 10000ton Per YearProduct Description

92% Alumina Ceramic Ball for Wet GrindingDescription

This product are featured by high density and hardness, low wear lost, corrosion-resistance etc. They are the perfect high-efficient grinding media for milling glaze/frit, pigment, ceramic materials, and various mine ore powder, they are using ceramics, cements, paints, refractories, inorganic mineral powders etc...

Appearance:

Applied for dry grinding, wet grinding, mineral grinding, quartz grinding, lineston grinding, iron ore grinding, cement grinding, ceramics plants grinding, pigment grinding, mineral ore grinding, breaking platns.

Applied for ball mill, grinding machine, pot mill, librating mill, pebble mill, Attrition Mill, rod mill, grinding mill, grinding machine, ball grinding mill

Specification

Size: 1mm, 3mm, 6mm, 9mm, 13mm, 16mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm, 70mm, 95mm

Technical data

1: 92% 95% 68% Alumina content series

A) Al2O3 ≥ 92%

B) Water absorption <0.01%

C) Bulk density ≥ 3.63 g/cm3

D) Mosh hardness: 9

E) Color: White

2: 95% High-alumina grinding ball

A) Al2O3 ≥ 95% Sio2<3.8%, others: ~3%

B) Water absorption <0.01%

C) Bulk density ≥ 3.7 g/cm3

D) Mosh hardness: 9

E) Color: White

F) self abrasion loss: <0.008%

3: 68% Medium alumina grinding ball series:

A) Al2O3: 65%~75%

B) Bulk density ≥ 2.93g/cm3

C) Mosh hardness: 8 grade

D) self abrasion loss: 0.01

E) Color: White or brown

| Items | Proportion | Items | Proportion |

| Al2O3 | 92% | SiO2 | <6.5% |

| others | ~2% |

| Items | Proportion | Items | Proportion |

| Hardness: Mohr's | 9 | self Abrasion Loss (24hour) | <0.01% |

| Density(g/cm3) | 3.6g/cm3 | Water Absorption | <0.01% |

| Color | White | Ball method | By cool isostatic-pressing Or by rolling |

95% Alumina ball chemical and physical introduction :

| Items | Proportion | Items | Proportion |

| Al2O3 | 95% | SiO2 | <3% |

| others | ~2% |

Physical Analysis:

| Items | Proportion | Items | Proportion |

| Hardness: Mohr's | 9 | self Abrasion Loss (24hour) | <0.01% |

| Density(g/cm3) | 3.74g/cm3 | Water Absorption | <0.01% |

| Color | White | Ball method | By cool isostatic-pressing Or by rolling |

68% Alumina ball chemical and physical introduction :

| Items | Proportion | Items | Proportion |

| Al2O3 | 68.62% | SiO2 | 21.2% |

| others | ~10.18% |

Physical Analysis:

| Items | Proportion | Items | Proportion |

| Hardness: Mohr's | 7-8 | self Abrasion Loss (24hour) | <0.03% |

| Density(g/cm3) | 3.g/cm3 | Water Absorption | <0.1% |

| Color | creamy white | Ball method | By cool isostatic-pressing Or by rolling |