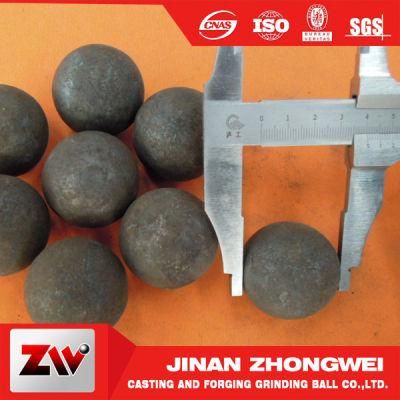

60mn Forged Steel Grinding Balls for Ball Mill

Jinan Zhongwei Casting and Forging Grinding Ball Co., Ltd.- Material:Iron

- Content:100%

- Usage:Mine, Cement Plant, Power Station

- Processing Type:Forging and Casting

- Size:20-150mm

- Color:Metallochrome

Base Info

- Model NO.:45#, 60MN, B2, B3

- Customized:Customized

- Raw Material Heating:by Electric Furance

- Heat Treatment Method:Oil,Air Quenching

- Certification:ISO9001:2008

- Transport Package:Container Bag, Steel Drum

- Specification:20-150mm

- Trademark:Jinan zhongwei

- Origin:Shandong Jinan

- HS Code:73261100

- Production Capacity:1000000

Description

MaterialChemical elements C Si Mn P/S Cr B2 0.72-0.85 0.17-0.37 0.7-1.0 <0.04 0.4-0.6 60Mn 0.55-0.65 0.17-0.37 0.7-1.0 <0.04 <0.25 45# 0.42-0.50 0.17-0.37 0.5-0.8 <0.035 ≤0.25 B3 0.58-0.66 1.6-1.9 0.65-0.8 <0.025 0.7-0.9

Hardness

Material

25mm-50mm

HRC

60mm-90mm

HRC

100mm-125mm

HRC

Surface Core Surface Core Surface Core B2 60-65 58-62 58-63 50-55 56-60 40-45 60Mn 58-63 55-60 58-63 40-45 56-60 30-35 45# 55-58 45-55 55-58 30-35 50-55 25-30 B3 58-62 56-60

Production Description

1) Traditional Forged

Raw material →Cutting →Heating → Water quenching → Tempering

2) Auto Hot Rolling

Raw material →Hot Rolling Mill → Water Quenching → Tempering

Packing

Steel drum (800-950kg per drum) &Container Bag (1000kg per bag)

QC&QI

1) Raw material: Size, Chemcial elements, Microstructure quality control (LAIWU STEEL)

2) Production Technical: Cutting Size, Heating Temperature, Quenching Technical, Tempering control.

3) Grinding Balls: Hardness, Size, Chemcial elements, Breakage Rate Checking

4) Thrid-Pary: SGS, BV ISO, TUV, COTECNA, AsiaInspection etc.

Hardness

Material

25mm-50mm

HRC

60mm-90mm

HRC

100mm-125mm

HRC

Production Description

1) Traditional Forged

Raw material →Cutting →Heating → Water quenching → Tempering

2) Auto Hot Rolling

Raw material →Hot Rolling Mill → Water Quenching → Tempering

Packing

Steel drum (800-950kg per drum) &Container Bag (1000kg per bag)

QC&QI

1) Raw material: Size, Chemcial elements, Microstructure quality control (LAIWU STEEL)

2) Production Technical: Cutting Size, Heating Temperature, Quenching Technical, Tempering control.

3) Grinding Balls: Hardness, Size, Chemcial elements, Breakage Rate Checking

4) Thrid-Pary: SGS, BV ISO, TUV, COTECNA, AsiaInspection etc.