Grinding Media Grinding Balls High Quality Forged Balls

Shandong Huamin Steel Ball Joint-stock Co., Ltd.- Material:Stainless Steel

- Content:>90%

- Usage:Construction, Machinery, Chemical

- Processing Type:Rolling Type

- Size:Big

- Color:Green

Base Info

- Model NO.:20-150

- Customized:Customized

- Specification:1000kg

- Trademark:huamin

- Origin:China

- HS Code:7326110000

- Production Capacity:100000ton,Year

Description

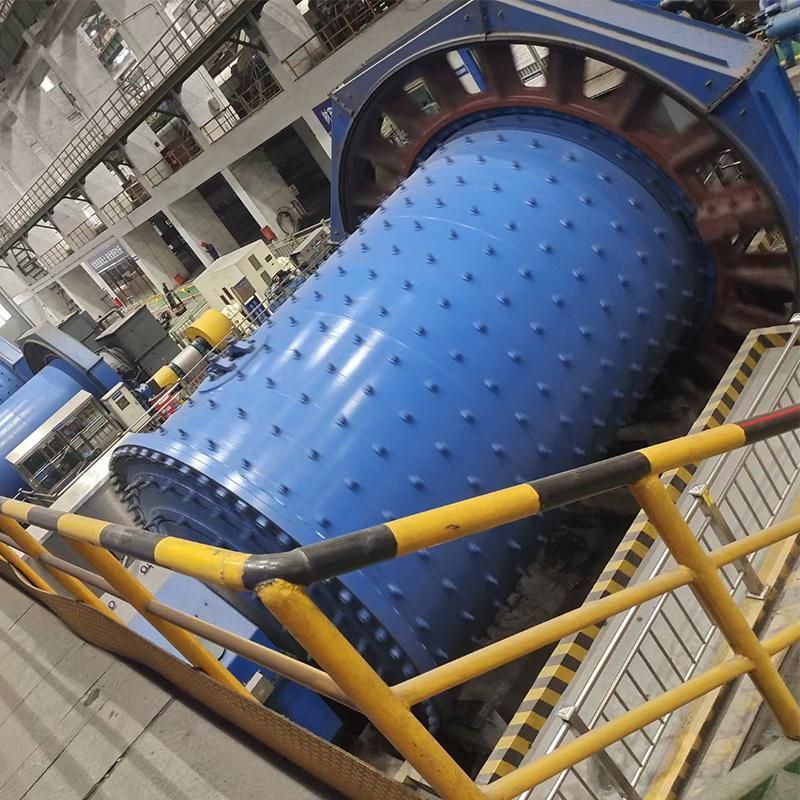

Ball mill steel balls are grinding media for ball mills in iron ore, copper ore, gold ore, molybdenum ore and other mining beneficiation industries, including coal mills in various thermal power plants and ball mills in cement plants. Low chromium balls are popular because of their low prices. It is welcomed by customers, and with the improvement of the production process, the low-chromium balls already have very good quality and use effect.

Ball mill steel balls are grinding media for ball mills in iron ore, copper ore, gold ore, molybdenum ore and other mining beneficiation industries, including coal mills in various thermal power plants and ball mills in cement plants. Low chromium balls are popular because of their low prices. It is welcomed by customers, and with the improvement of the production process, the low-chromium balls already have very good quality and use effect.1. Product Specifications: Φ20-150mm

2. Application areas: various metal mines (gold, copper, iron, molybdenum, alumina, lead-zinc), cement plants, power plants and other grinding industries.

3. Process characteristics:1. The raw materials are all bearing steel scraps, which contain precious metal elements such as copper, molybdenum, and nickel, which can effectively improve the basic structure of the product, make the grains more refined, and the structure more dense. The content of sulfur and phosphorus in the product is extremely low, and the product is not easy to peel off and deform during use; the surface is smooth and round.

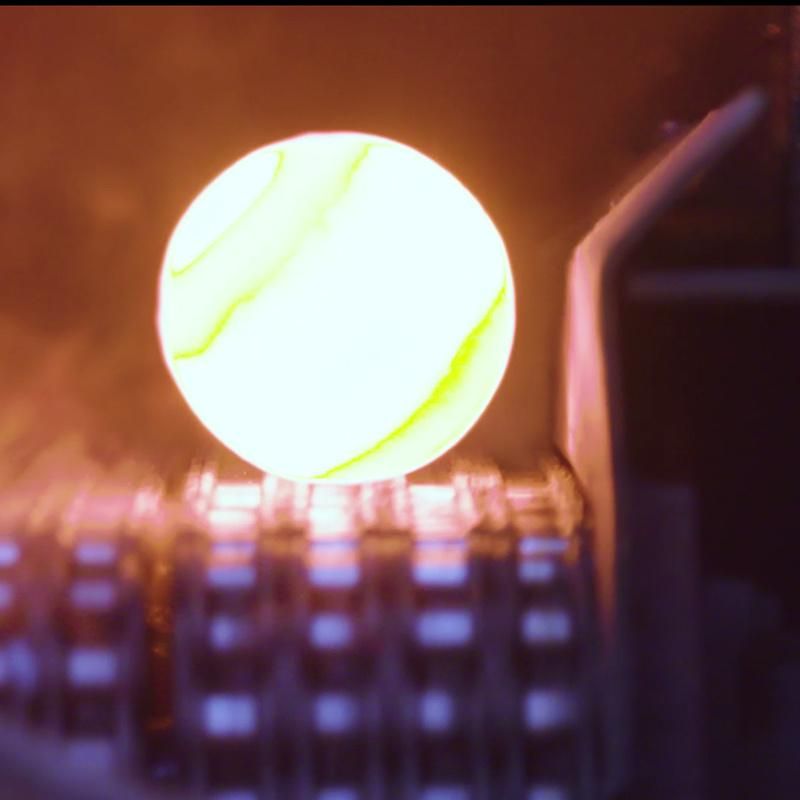

2. Adopt single refining process. All products are processed and produced by medium frequency electric furnace, which effectively ensures the stability of melting temperature.

2. Adopt single refining process. All products are processed and produced by medium frequency electric furnace, which effectively ensures the stability of melting temperature.3. Fully automatic push rod heat treatment oil quenching production line is adopted, with advanced technology and good hardenability. It greatly improves the uniformity of product hardness, improves the relationship between hardness and toughness, and thus improves the wear resistance of the product.

Fourth, the detection process of steel balls

Appearance inspection of steel balls refers to the process of short-term inspection of steel balls of non-air-conditioning accessories during the processing of steel balls. The appearance inspection of the steel ball mainly includes appearance scratches, rust, and appearance mottled. Steel balls are widely used in electric power, building materials, mining, metallurgy and other fields.

The influence of different raw materials on the quality of steel balls: steel balls, cast iron balls, alloy steel balls, etc., the density of different raw materials is different, the density of steel is greater than that of cast iron, and the density and content of alloy steel are different due to the density and content of primary alloying elements.

5. Transportation

5. TransportationIt is transported by car in China, packed in tons of bags, 1 ton/bag

Outside China, it is shipped by sea, and it can be packed in tons of bags according to the needs of customers. If the distance is long, it can also be packed in iron drums, 850 kg/drum. Customers can choose between the two packaging methods.

If you have other questions, please feel free to communicate with us to solve them!