Taa Brand Stainless Steel Cut Wire Shot SUS304 SUS430 SUS410

Zibo Taa Metal Technology Co., Ltd- Natural Abrasive Type:Stainless Steel

- Artificial Abrasive Type:Stainless Steel

- Application:Shot Blasting and Shot Peening

- Function:Surface Finish

- Source:Artificial Abrasives

- Particle Size:Abrasive

Base Info

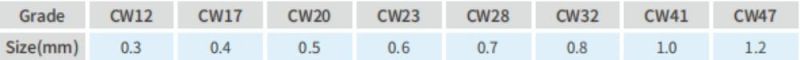

- Model NO.:0.3,0.4,0.5,0.6,0.7,0.8,1.0mm etc

- Hardness:HRC32-42

- Product Name:Taa Brand Surface Cleaning High for Performance Su

- Abrasive Grain Sizes:0.3mm-1.2mm

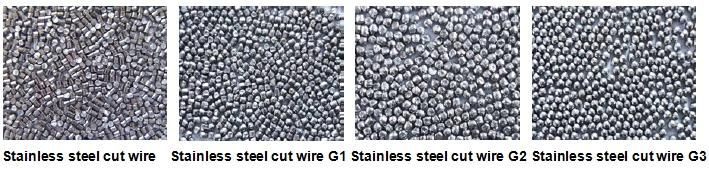

- External Form:Cylindrical,Conditioned

- Microstructure:Ferrite and Austenitic

- Certification:ISO

- Samples:500g

- Customized Support:OEM

- MOQ:1 Ton

- Payment:T,T

- Package:25kg*40bags

- Material:Steel

- Density:≥7.20g,cm3

- Type:Blasting Media

- Model Number:SUS430, SUS302, SUS304, SUS410

- Transport Package:Ton Bag or Customized

- Specification:0.2,0.3,0.5,0.6,0.8,1.0,1.2,1.5mm etc

- Trademark:TAA Brand

- Origin:China

- HS Code:72051000

- Production Capacity:150, 000 Tons,Year

Description

Overview

1.TAA produce products following SAE standard, also can produce customized abrasives catering for customers' various requests, benefiting from our advanced production facility, technology and quality control system.

1.TAA produce products following SAE standard, also can produce customized abrasives catering for customers' various requests, benefiting from our advanced production facility, technology and quality control system.

2.Our R & D technology department has 40 people, who will provide you with consultation and feedback. At the same time, we can also provide you with absolutely free samples to meet your needs. We will try our best to provide you with ideal services and products.

3.The test center has perfect quality testing equipments, such as carbon-sulfur analyzer, German QUANTRON Direct-Read Spectrograph, metallographic micro-hardness tester, Screen tester,ERVIN life tester and other quality control equipment. can check composition, hardness,size distribution and service life etc, ensuring products meet the international standards or the requirements of customers TAA committed to the provision of high-end surface treatment equipment and solutions.

TAA committed to the provision of high-end surface treatment equipment and solutions.

It has finally realized the surface treatment industry chain from metal abrasives to surface treatment equipment and overall contracting services, and as a "surface treatment integrated service provider", helping users improve production efficiency and reduce operating costs by providing high-quality products and overall services.

Product Description

Product Parameters

Product Application

Our Advantages

Company Profile

Production process

Certifications

Why choose us

1.TAA produce products following SAE standard, also can produce customized abrasives catering for customers' various requests, benefiting from our advanced production facility, technology and quality control system.

1.TAA produce products following SAE standard, also can produce customized abrasives catering for customers' various requests, benefiting from our advanced production facility, technology and quality control system.2.Our R & D technology department has 40 people, who will provide you with consultation and feedback. At the same time, we can also provide you with absolutely free samples to meet your needs. We will try our best to provide you with ideal services and products.

3.The test center has perfect quality testing equipments, such as carbon-sulfur analyzer, German QUANTRON Direct-Read Spectrograph, metallographic micro-hardness tester, Screen tester,ERVIN life tester and other quality control equipment. can check composition, hardness,size distribution and service life etc, ensuring products meet the international standards or the requirements of customers

TAA committed to the provision of high-end surface treatment equipment and solutions.

TAA committed to the provision of high-end surface treatment equipment and solutions.It has finally realized the surface treatment industry chain from metal abrasives to surface treatment equipment and overall contracting services, and as a "surface treatment integrated service provider", helping users improve production efficiency and reduce operating costs by providing high-quality products and overall services.