-

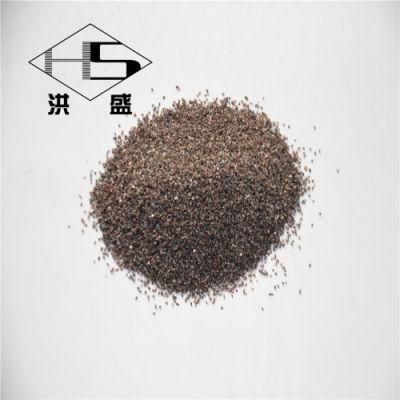

Brown Fused Alumina F8-F220, P8-P220

Basic Info. Model NO. BFA F12-F220, 24#-220#, 0-1-3-5-8mm, 220#-8000#

-

Garnet 80 Mesh / Blasting Grit Granite Sand / Garnet Sand Blasting

Basic Info. Model NO. BY-G

-

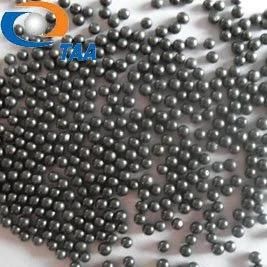

Taa Brand Cast Alloy Steel Shot S330 for Shotblasting Pre-Treatment

Overview Product DescriptionProduct ParametersProduct ApplicationCompany ProfileProduction processCertificationsWhy choose usSimilar product stainless steel shot Drum Type Shot Blast Machine shot blasting space parts

-

Brown Aluminum Oxide Grade a/B/C

Basic Info. Model NO. BFA F12-F220, 24#-220#, 0-1-3-5-8mm, 220#-8000#

-

High Quality Wholesale Black Crystal Sic Silicon Carbide

Chemical CompositionSIC(%)F.C(%)Fe2O3(%)F12-F90≥97≤0.2≤0.2F90-F120≥97≤0.2≤0.2F120-F220≥97≤0.3≤0.2F220-F240≥97≤0.3≤0.3F240-F325≥97≤0.4≤0.3F325-F500≥97≤0.4≤0.3

-

Brown Alumina Oxide for Sports Fields Wear-Resistant Material

Overview Product DescriptionProduct ParametersPurposeSpecificationChemical composition(%)Magnetic material ≤Al2O3(≥)Fe2O3(≤)SiO2≤TiO2≤For abrasiveF grit4#-80#95.00.31.53.00.0590#-150#94.00.03180#-240#93.03.50.02P grit8#-80#95.00.21.23.00.05100#-150#94.00.03180#-220#

-

Refractory Cement Castable Black Silicon Carbide Powder F240 for Abrasive

Chemical CompositionSIC(%)F.C(%)Fe2O3(%)F12-F90≥97≤0.2≤0.2F90-F120≥97≤0.2≤0.2F120-F220≥97≤0.3≤0.2F220-F240≥97≤0.3≤0.3F240-F325≥97≤0.4≤0.3F325-F500≥97≤0.4≤0.3

-

High Purity White Alumina Oxide/ Aluminum Oxide for Abrasive and Sandblasting

Basic Info. Model NO. WFA/WA F12-F800, 10#-220#, 0-1-3-5-8mm, 240#-8000#

-

Taa Brand SUS304 Stainless Steel Cut Wire Shot 1.4mm

Overview Product DescriptionProduct ParametersProduct ApplicationOur AdvantagesCompany ProfileProduction processCertificationsWhy choose us1.TAA produce products following SAE standard, also can produce customized abrasives catering for customers' various requests, benefiting from

-

30 36 46 60 80 Mesh Brown Fused Alumina Manufacturer

Overview Product DescriptionBrown fused Alumina (also know as brown corundum or brown aluminium oxide) is produced by fusion of calcined bauxite in Electric arc furnaces at high temperature of about 2000 degree celsius. The end product has low iron content making it particularly v