Wear Resistant Alumina Ceramic Cylinder Grinding Media/Ceramic Balls with Low-Wear Rate

ZIBO QIMINGXING NEW MATERIAL INCORPORATED CO., LTD.- Material:Alumina

- Content:>90%

- Usage:Construction, Machinery, Chemical, Petroleum, Grind, Refractory Material

- Processing Type:Isostatic Pressing Type

- Size:Middle

- Color:White

Base Info

- Model NO.:alumina

- Customized:Customized

- Quality:First Class

- Delivery Time:15~25 Days as Your Request

- Samples:Free Samples Can Be Provided

- MOQ:50kg

- Export Markets:Global

- Sample Time:2-5days

- Bulk Order Time:10-30days

- Transport Package:Safe Carton with Pallet

- Specification:92%95%99%

- Trademark:qimingxing

- Origin:Shandong

- HS Code:6909120000

- Production Capacity:18000

Description

Basic Info.

Model NO. alumina Customized Customized Quality First Class Delivery Time 15~25 Days as Your Request Samples Free Samples Can Be Provided MOQ 50kg Export Markets Global Sample Time 2-5days Bulk Order Time 10-30days Transport Package Safe Carton with Pallet Specification 92%95%99% Trademark qimingxing Origin Shandong HS Code 6909120000 Production Capacity 18000Product Description

Wear Resistant Alumina Ceramic Cylinder Grinding Media/Ceramic Balls with Low-Wear rate

1.Size:

| SERIES | SIZE |

| Cylinder | φ12*12mm;φ15*15mm;φ23*23mm; φ20*20mm;φ20*10mm; φ25*20mm; φ25*25mm;φ30*30mm;φ32*32mm; φ40*40mm;φ50*50mm;φ60*60mm |

| Half cylinder | φ20*10Half;φ20*20Half; φ20*25Half; φ30*30Half; φ40*40Half |

| Conical cylinder | φ50/45*50;φ33/28*17mm; φ32/28*32mm;φ33/28*33mm |

| Cylinder with slot | φ21*21,φ31*31 or Half cylinder |

| Fish Cylinder | can be customized |

2. Detailed description:

In aggressive industrial applications,equipment where high impact , high abrasion inevitably suffer mechanical attack, chemical attack, corrosion, or by a combination of these three modes.

Ultraming Ceramics can offer various of ceramic liner plate for customer's abrading environment. Composite ceramic wear liner is intended for the toughest applications with very high materials. when a combination of extreme wear and impact resistance ans long wear life is needed , Ultraming offer composite ceramic wear liner with large and hard ceramic bricks vulcanized into a matrix of wear resistant rubber .due to its elastic properties the rubber acts as a dampener. It makes it possible to use this product in applications with a lot of impact without the risk of crushing the ceramic bricks .

2.Product features:

> High hardness

> Superior abrasion and impact resistance

> Corrosion and chemical resistance

> Light weight

3.Working conditions: Grinding or can be used to make composite plates

01.The main benefits of the ceramic rubber composites:

- Excellent wear resitance

- Excellent anti-impact due the elastic property of the rubber

- Easy to be installation and then reduce downtime

- Reduce the sould pollution.

02. Applicatiion of equipments

- Bins

- Feeders

- Chutes

- Bunkers

- Storages

Factory:

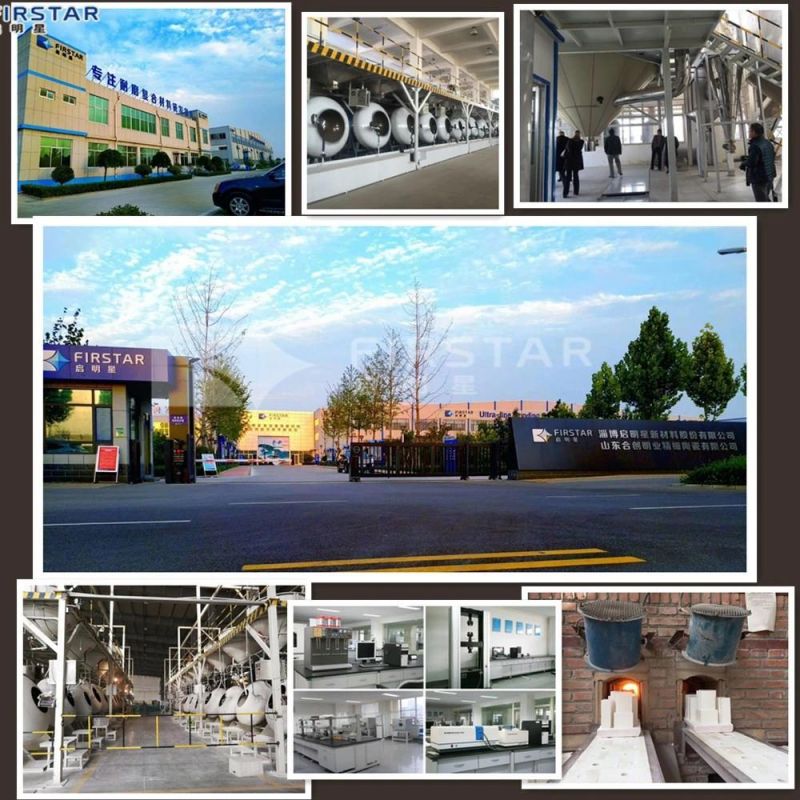

Zibo Qimingxing New Material Incorporated Co., Ltd has been founded in 1997 and covered the area of 160mu,having more than 350 staffs in which the technical staffs account for 35%. The company has set up their wholly owned subsidiary, Shandong Ultraming Fine Ceramics Co., Ltd, Shandong Yilaisheng New Material Co., Ltd, Zibo Xingao New Material Research Institute Co., Ltd. The annual production of wear resistant ceramic and grinding media is 18000 tons. Our factory passed the ISO 9001:2015 standard quality management system certificate and successfully listed on the new OTC market in January 2017. The stock code is 870601.

Our products are also exported to many courtries and build long-term business relationship with customers.

Every year we also go to many exhibitions all over the world.

We accept customized designs, packing, logo or custom material. We can make custom design based on your inquiry. We provide NDA agreement to keep your design in private.

Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee your satisfaction.

Our business staff have 7~10 years of experience in the industry and can provide you with quality services. All your inquiries will be responded within 24 hours.

PROFESSIONAL

FULL SERVICE

PROTECTION FOR YOUR BENEFIT

Any inquiry pls feel free to contact us for more communication.

What can we do for you?1. Sample is available.

2. Independent R&D, ISO manufacture, precise quality standards, modern logistics management, and sound marketing strategy.

3. Inquiry replied within 24 hours.

4. Patented products.

5. Some extra accessories can be supplied.

6.The larger quantity you order,the more competitive prices you'll get.

7. Necessary Certificates can be supplied.

Why To Choose Us

1. What's your MOQ ;

We have no MOQ for your try orders.It won't occupy too much of your money to help you to test the market you're going to enter.

2. R & D Center and Factory:

We have our own R & D center and factory, so we can supply you products at competitive price.

3. Good Service :

We treat clients as friends.

4. Good Quality :

We import top quality accessories to manufacture our products, we have confident we can offer you the best quality.

5. After-sales service:

Wearing accessories comes with the products to help you to reduce the repair bill.