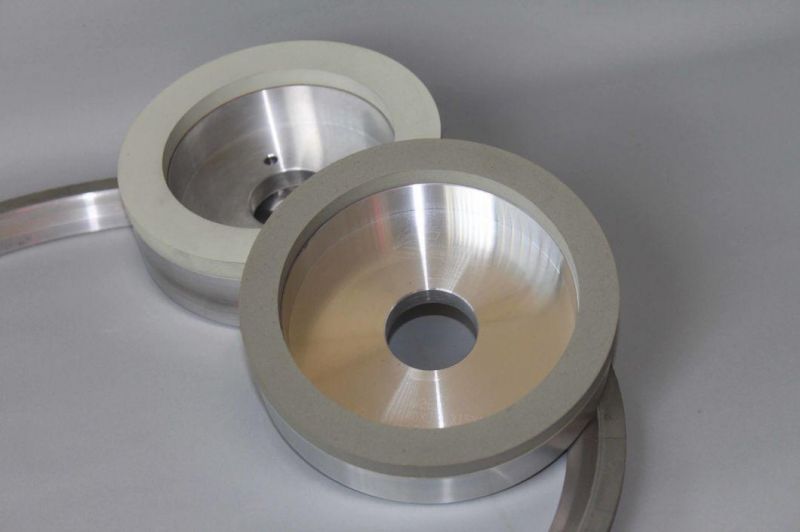

Vitrified Bond Diamond Grinding Wheels for PCD/PCBN Insert. Superabrasive Tools

Taizhou Sumeng Grinding Wheel Co., Ltd.- Material:Diamond

- Abrasive:Superabrasive

- Shapes:Edge Shape

- Types:Surface Grinding Wheel

- Grain Size:280#

- Cylindricity:<1

Base Info

- Model NO.:6A2, 11A2, 12A2, 2A2

- Circular Degree:<1

- Technics:Sinter

- Working Style:Tool Grinding

- PCD Peripheral Grinding:Grinding of PCD and CBN Cutting Tools

- CBN Peripheral Grinding:Pre-Grinding Universal Grinding Finish Grinding

- Vitrified Bond Diamond Wheel:Shape 6A2h 11A2 11A2b 2A2t 11A2h 12A2t 15A2

- PCD and CBN Peripheral Grinding:Grinding Tools for The Production of PCD

- Transport Package:by Carton

- Specification:EN 12413

- Trademark:SAILI, BONDFLEX, SUMENG

- Origin:China

- HS Code:68042210

- Production Capacity:10000 Tons,Year

Description

Basic Info.

Model NO. 6A2, 11A2, 12A2, 2A2 Circular Degree <1 Technics Sinter Working Style Tool Grinding PCD Peripheral Grinding Grinding of PCD and CBN Cutting Tools CBN Peripheral Grinding Pre-Grinding Universal Grinding Finish Grinding Vitrified Bond Diamond Wheel Shape 6A2h 11A2 11A2b 2A2t 11A2h 12A2t 15A2 PCD and CBN Peripheral Grinding Grinding Tools for The Production of PCD Transport Package by Carton Specification EN 12413 Trademark SAILI, BONDFLEX, SUMENG Origin China HS Code 68042210 Production Capacity 10000 Tons/YearProduct Description

With special vitrified bond, We created a high efficient diamond wheels suitable for sharpening PCD/PCBN insert. The advantages of our bond are as follows:

The perfect grinding process efficiency

Shortened shut-down grinder times

High machining accuracy

Remarkably higher life in comparison with traditional grinding wheels

Short grinding times

Very good tool profile stability

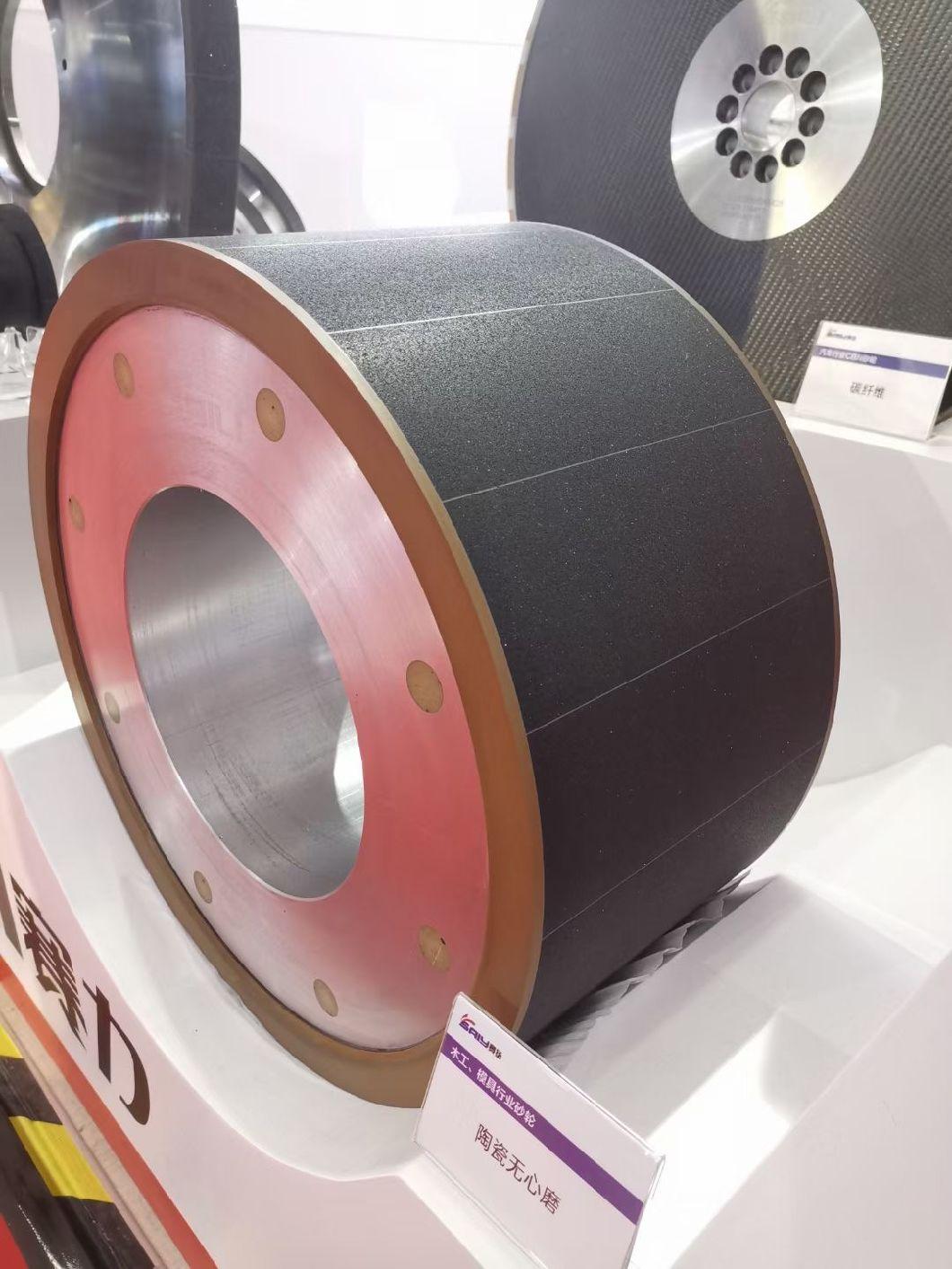

We develop a generation of grinding tools specially for the production of modern PCD and CBN cutting tools

GRINDING OF PCD AND CBN CUTTING TOOLS

Products and application benefits

Cutting-edge chipping less than 10um

Shorter set-up times as a results of longer dressing intervals

Process stability thanks to an innovative bond system

Higher cutting ability with high profile retention

Extensive stock range

PCD and CBN peripheral grinding

PCD peripheral grinding

CBN peripheral grinding

Pre-grinding Universal grinding Finish Grinding Fine grinding

Shape 6A2H 11A2 11A2B 2A2T 11A2H 12A2T 15A2T

Vitrified Bond Diamond Wheel Shape 6A2H 11A2 11A2B 2A2T 11A2H 12A2T We develop a generation of grinding tools for the production of PCD and CBN cutting tools.