SAE Steel Grit for Sandblasting/Surface Polishing

Jinan Junda Industrial Technology Co., Ltd.- Natural Abrasive Type:Steel Grit G18

- Artificial Abrasive Type:Artificial

- Application:Shotpeening

- Function:Sandblasting Stainless Steel

- Source:Artificial Abrasives

- Particle Size:Abrasive

Base Info

- Model NO.:G18 G25 G40

- Hardness:Gh, Gp, Gl

- Name:Steel Grit G18 G25 G40

- Cr:0.26%

- Shape:Spherical,Round

- Mohs Hardness:40-51, 50-55, 60-68HRC

- Density:7.4 g,cm3

- Micro-Structure:Martensite , Bainite

- Diameter:0.2-2.5mm

- Durability:3200 Times

- Mn:0.6-1.2%

- C:0.8-1.2%

- P:<0.05

- Si:0.4-1.2%

- Standard:SAE

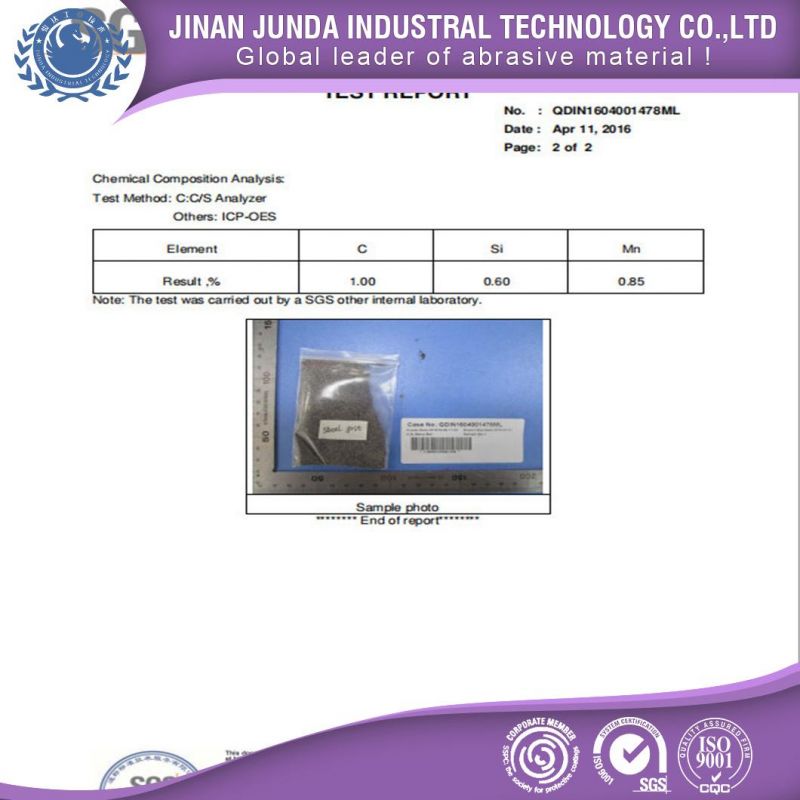

- Certificate:SGS

- Applications:machinery Part

- Transport Package:25kg Bags, 1ton in 1 Bag

- Specification:1.2mm

- Trademark:Honest Horse

- Origin:Shandong

- HS Code:720510

- Production Capacity:3000tons Per Month

Description

Application 1.Blast cleaning: Used for blast cleaning of casting, die-casting,forging; sand removal of casting, steel plate, H type steel, steel structure.

2..Rust removal: Rust removal of casting, forging, steel plate, H type steel,steel structure.

3.Shot peening: Shot peening of gear, heat treated parts.

4.Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure.

cleaning the casting sand and burnt -on sand of the casting to make the surface get good cleanliness and required roughness, so that can be benefit to the subsequent processing and coating.

7.Steel grit package

1.25kg/bag(pp bag or paper bag) then 40 bags in one ton bag/pallet ,

2.one ton one bag

all packages are lined with waterproof materials

We can also pack according to your requirement.

8.Our service

1.we can supply sample for free.

2.Customized Service

a.Product---We can produce various size abraisve according to the customers' requirements.

b.Package---The products can be packaged as customers' requirements.

3.After-sales Service

a.Our products passed ISO9001 standard, and we control the testing procedure strictly.

b.If there are quantity problems,package problems,delivery problems,or any other problems,our

company will seriously investigate the event and give customers a satisfying reply.

9.Company information

Jinan Junda Industrial Technology Co.,Ltd. is located in Jinan,Shandong Province,China,which is

the daughter company of Honest Horse (CHINA) Holding Limited.We are the manufacturer of abrasive media for 15 years experience in north China.

10.FAQ

1.Our payment terms:

a.T/T 50% advance payment then the rest 50% payment pay us when get the scanned B/L from our E-mail

b.L/C 100% irrevocable L/C at sight

2.Delivery time:

3-5 work days after get the advance payment

3.Advantages:

15 years exprierence

SAE ISO9001 certificate

on-time shipment

support after-sale service

11.OUR MINE PRODUCTS:

1.Bearing steel grit

2.Cast steel grit

3.Steel shot

4.Low carbon steel shot

5.Steel cut wire

6.Garnet sand

7.Glass beads

More details, please contact with Anna

we will recommend you the most cost-effective product for your applications!

2..Rust removal: Rust removal of casting, forging, steel plate, H type steel,steel structure.

3.Shot peening: Shot peening of gear, heat treated parts.

4.Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure.

4.steel shot equipment

5.Steel grit Test report

6.Steel grit Applications

1. Fettling

cleaning the casting sand and burnt -on sand of the casting to make the surface get good cleanliness and required roughness, so that can be benefit to the subsequent processing and coating.2. Steel Plate Surface Preparation

Cleaning the oxide skin, rust and other impurity by shot Blasting, then using the vacuum cleaner or the purified compressed to clean up the steel products surface.3. Engineering Machinery

Machinery cleaning can effectively remove the rust, welding slag, and oxide skin, eliminate the welding stress,and increase basic binding force between rust removing coating and the metal ,thus greatly enhancing the derusting quality of engineering machinery spare part.4. Stainless Steel Plate Cleaning

To achieve clean, luminous, exquisite burnish surface treatment of stainless steel plate, it is a must to select the suitable abrasive materials to remove the scale from cold rolled stainless steel surface. According to different grades,the stainless steel surface needs to select different diameter abrasives and proportion to process. Compared to the traditional chemical process, it could lower the cleaning cost and achieve green production5. Steel Structure

Steel structure,H section,C section and angle steel are widely applied in the modern construction industry. They all need rust and oxide skin removal treatment to achieve the good anti-corrosion property and aesthetic property.6. Pipeline Anti-Corrosion

The steel pipes need surface treatment in order to strengthen the corrosion resistance. By polishing cleaning removing the oxide and the attachments achieve the requested rust removing grade and the grain depth. Not only cleaning surface but also satisfy the adhesion between steel pipe and coating, achieve good anti-corrosion effect.7. Body Section

The metal abrasives quality used for sand blasting body section directly affect the quality and comprehensive cost factor in terms of the sand blasting efficiency,girder coating, painting, kinetic energy and abrasiveconsumption. Withthe new coating protection performances standard (PSPC) release, there is a higher request to the piecewise sand blasting quality. Therefore, the metal abrasives quality is very important in the sand blasting.

7.Steel grit package

1.25kg/bag(pp bag or paper bag) then 40 bags in one ton bag/pallet ,

2.one ton one bag

all packages are lined with waterproof materials

We can also pack according to your requirement.

8.Our service

1.we can supply sample for free.

2.Customized Service

a.Product---We can produce various size abraisve according to the customers' requirements.

b.Package---The products can be packaged as customers' requirements.

3.After-sales Service

a.Our products passed ISO9001 standard, and we control the testing procedure strictly.

b.If there are quantity problems,package problems,delivery problems,or any other problems,our

company will seriously investigate the event and give customers a satisfying reply.

9.Company information

Jinan Junda Industrial Technology Co.,Ltd. is located in Jinan,Shandong Province,China,which is

the daughter company of Honest Horse (CHINA) Holding Limited.We are the manufacturer of abrasive media for 15 years experience in north China.

10.FAQ

1.Our payment terms:

a.T/T 50% advance payment then the rest 50% payment pay us when get the scanned B/L from our E-mail

b.L/C 100% irrevocable L/C at sight

2.Delivery time:

3-5 work days after get the advance payment

3.Advantages:

15 years exprierence

SAE ISO9001 certificate

on-time shipment

support after-sale service

11.OUR MINE PRODUCTS:

1.Bearing steel grit

2.Cast steel grit

3.Steel shot

4.Low carbon steel shot

5.Steel cut wire

6.Garnet sand

7.Glass beads

More details, please contact with Anna

we will recommend you the most cost-effective product for your applications!