20mm-150mm Good Wear Rate Forged Steel Ball

Shandong Shengye Grinding Ball Co., Ltd.- Material:Stainless Steel

- Content:>90%

- Usage:Construction, Chemical, Grind, Mining, Cement Plant

- Processing Type:Forged & Cast

- Size:Middle

- Color:Brown

Base Info

- Model NO.:SY19008010

- Customized:Customized

- Product Name:Forged Steel Ball

- Process:Forged, Hot Rolled

- Certificate:TUV ISO 9001 , BV , SGS

- Service:Free Samples

- Heat Treatment:Quenching + Tempering

- Hardness:50-65HRC

- Breakage Rate:<1%

- Impact Toughness:>12ak.J,Cm^2

- Transport Package:Steel Drums & Flexible Container Bags

- Specification:45#, 50Mn, 60Mn, 65Mn, B2, B3, BL, BG

- Trademark:ShengYe

- Origin:Shandong, China

- HS Code:73261100

- Production Capacity:100000

Description

Production Process

1.Material Inspection

Custom the raw materials -- testing the chemical composition of raw materials by spectrometer -- Put the qualified steel material into workshop

2. Forging or Hot rolling

Put the raw materials into the intermediate frequency furnace and heat them to a certain temperature -- Hammer forged or hot rolled process -- cooling -- Quenching -- Insulation -- tempering

3. Quality Inspection

Testing the impact value -- testing the surface hardness -- cutting the steel ball by laser cutting machine --testing the core hardness -- Observe the metallographic structure by microscope -- testing the forged Steel ball fatigue life by drop tester

4. Packing and delivery

packing the qualified forged steel ball--Storage--Delivery from factory

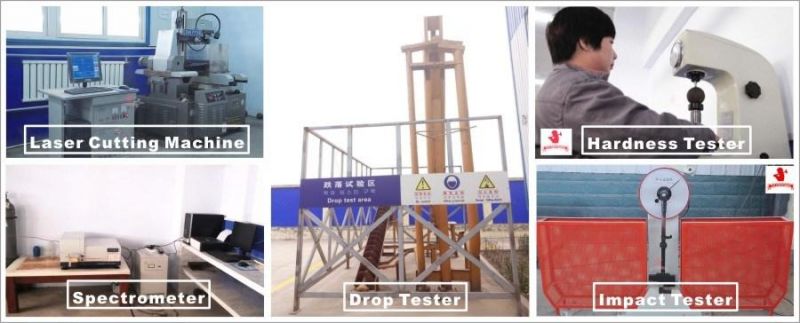

Testing Equipment

We have a first-class laboratory and equipped with advanced testing equipment to ensure the quality:

Spectrometer--The wear resistance of forged steel ball is mainly determined by its chemical composition.

Hardness tester-- Testing the surface hardness of forged steel ball.

Laser cutting machine-- Cuting the core of forged steel ball.

Impact tester-- Ball mill with a diameter more than 6m, the larger the impact value, the lower the breaking rate.

Microscope-- Observe the density and structure of forged steel ball.

Drop tester--Testing the service life of the forged steel ball.

Packing and Delivery

1. Transpotation

Ocean shipping ( Or Customers designated transportation mode.)

2. Packing Way

a. steel drums (850-930kgs/drum) b. flexible container bags(1ton/bag)

3.Delivery Time

Witnin 15-20 days after received the payment or LC at sight. (Generally it is 5-10 days if the forged steel ball is in stock. or it is 15-20 days if the forged steel ball is not in stock, it is according to quantity.)

4. Payment Terms

Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,

balance before shippment.

Our Service

1.Free samples

we could offer free forged steel ball samples, you only need to pay the freight cost.

2. After-sales service

Go abroad to visit regular customers several times every year;

Attend national exhibitions;

Pay return visit once a week after the forged steel ball is received, inquire about the usage situation so that we can help to solve possible problems promptly.

3.Sales areas

Our forged steel ball is exported to over 30 countries and regions including USA, Republic of Korea, Japan, Malaysia, Australia, Canada and South Africa, etc., well and universally received by clients. In order to better serve customers, we have set up the office in Malaysia, Chile, United States and Spain.

Certificate Show

Our forged steel ball has passed the TUV ISO9001, ISO14001, OHSAS 18001, SGS, BV ect. Certificates

Any question about the forged steel ball, pls feel free to contact us as below:

Ina / MANAGER

SHANDONG SHENGYE GRINDING BALL CO.,LTD