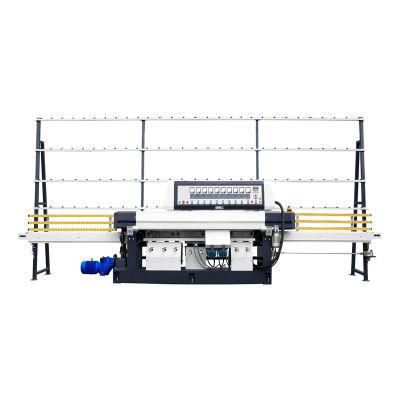

Straight Edge Glass Grinding Machine with 9 Motor Heads

Qingdao Toyo Industry Co., Ltd.- Type:Angle Grinder

- Power Source:Electricity

- Object:Milling Cutter

- Application:Construction

- Disc(Wheel) Type:Grinding Disc

- Material:Metal

Base Info

- Model NO.:straight edge grinding machine

- Working Style:High-speed universal

- Disc Diameter:None

- Variable Speed:Without Variable Speed

- Power:19.75kw

- Minimum Processing Size:70*70mm

- Certificate:CE

- Working Voltage / Frequency:380V , 50Hz 3p

- Minimum Size of Processed Glass:100X100 mm

- Maximum Size of Processed Glass:2440 mm X3660 mm

- Processing Glass Thickness:3 ~ 25mm

- Maximum Ground Grinding Amount:2.5mm

- Chamfering Width:0mm-3mm

- Total Power:19.75 Kw

- Conveying Speed of Main Drive:0.7-7 M ,Min

- Dimensions (L*W*H)):7000 mm X 1200 mm X 2500mm

- Table Height:750mm

- Total Weight:3000kgs

- Transport Package:Container

- Specification:7000*1200*2500mm

- Trademark:OEM

- Origin:China

- HS Code:8464201000

- Production Capacity:10000pieces,Year

Description

Grinding wheel

Maintenance

1. Before starting up, pay attention to check the wear of the grinding wheel. Replace the grinding wheel when it is worn out, and keep the nozzle position correct after changing the grinding wheel, otherwise you need to adjust.

2. Before grinding work, run the machine for 5 to 10 minutes in an empty state so that each motor is in the best operating state.

3.Lubrication

- The mechanical stepless speed changer located at the leftmost end of the host machine, the first time to change the lubricant after 300 hours of operation, the residual oil should be removed during the replacement, after that, for continuous work for more than 10 hours a day, every 3 months; Those who work for 10 hours, change every 6 months. When replacing, unscrew the ventilator of the reducer to refuel (the oil level is at the center of the oil mark). When draining, unscrew the oil drain plug at the bottom of the mechanical stepless reducer to release the dirty oil. It is recommended to use 150 # industrial gear oil (SY1172-80).

- The lubricant replacement system of the main transmission turbine directly connected to the mechanical stepless speed reducer is the same as that of the mechanical stepless speed reducer.

- For the grinding head carriage, the front rail moving carriage base is filled with N32 mechanical oil with an oil gun to maintain good lubrication.

- Regularly lubricate the swing lead screw bearing with grease to maintain good lubrication.

- For the main drive chain, add grease every other month. When filling, remove the front and rear shields at the left end of the main unit to fill. For the conveying chain of the conveying rail, refill the grease every two months. It is recommended to use ZL-1H (SY1413-80) synthetic lithium-based grease.

Waiting for your inquiry!

Don't hesitate to contact me for any questions you have!