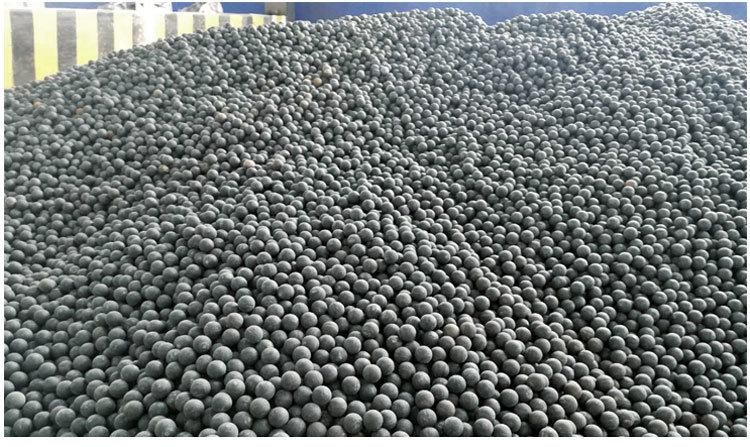

High Hardness Grinding Media Steel Ball for Metal Mines

Shandong Shengye Grinding Ball Co., Ltd.- Material:Alloy Steel, Carbon Steel, Round Steel, Steel Iron

- Content:>90%

- Usage:Construction, Machinery, Chemical, Grind

- Processing Type:Forging,Hot Rolling

- Size:Middle

- Color:Black

Base Info

- Model NO.:DIA 20mm-150mm

- Customized:Customized

- Product Name:Forged Steel Ball

- Certification:TUV ISO 9001 , BV , SGS

- Service:Customized &Free Samples

- Heat Treatment:Quenching+Tempering

- Steel Ball Hardness:60-65HRC

- Breakage Rate:<1%

- Impact Toughness:>12ak.J,Cm^2

- Other Application:Power Plant, Quartz , Silicon Sand Factory

- Transport Package:Steel Drums & Flexible Container Bags

- Specification:45#, 50Mn, 60Mn, 65Mn, B2, B3, BL, BG

- Trademark:ShengYe

- Origin:Shandong, China

- HS Code:73261100

- Production Capacity:100000

Description

· Mineral processing Plants

Forged Steel Ball Processing

1. Forged steel ball is hammer forged from selected high quality carbon and alloy steels. By hammer forged, the steel balls have good density and strengths in favor of impact grinding.

2. Hot rolled steel ball rolled direct from selected high quality carbon and alloy steels bar, followed by in-line heat treatment and uniform quenching, tailored to give even hardness throughout.

3. Forged steel ball need to be heat treated by quenching and tempering to become more wear resistant.

4. Sampling inspection at any time during the production process to ensure the forged steel ball is qualified

5. The produced forged steel balls are classified and stored according to different sizes and specifications.

6. Packed the forged steel ball according to customer's requirements, generally steel balls are packed by flexible container bags (1 ton /bag ).

7. Forged steel ball packing by steel drums is 850-930kgs/drum.

SHANGDONG SHENGYE GRINDING BALL CO.,LTD specializes in the production of forged steel ball for ball mill. Staff are trained and selected by strict overseas technology . The quality of forged steel ball is consistent and the specifications are complete. The annual output of diameter DIA 20MM-DIA 150MM forged steel ball is 100000 tons.

Due to the application of internationally advanced technology and manufacture experience ,our forged steel balls have the advantages of rubbing endurance, crashing tolerance and roundness persistence ,compared to other products in this field. We record the data for our products, follow up customers and drop in services at calling to solve customers' uncertainties.

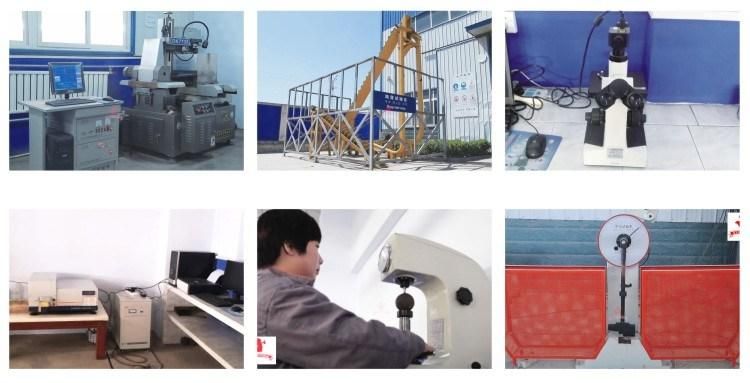

Quality control

_____________________________________________________________________________________________________________we have a first-class laboratory and equipped with advanced testing equipment to ensure the quality:

spectrometer ( The wear resistance of forged steel ball is mainly determined by its chemical composition. )

hardness tester (Testing the surface hardness of forged steel ball )

laser cutting machine (Testing the core hardness of forged steel ball)

impact tester (Ball mill with a diameter more than 6m, the larger the impact value, the lower the breaking rate. )

microscope ( Observe the density and structure of forged steel ball )

drop tester ( Testing the service life of the forged steel ball )

Certifications

____________________________________________________________________________________________________

Our forged steel ball has passed the TUV ISO9001, ISO14001, OHSAS 18001, SGS, BV ect. Certificates

After-service:

____________________________________________________________________________________________________

2. Attend national exhibitions;

3. Pay return visit once a week after the forged steel ball is received, inquire about the usage situation so that we can help to solve possible problems promptly.

A: We are a professional forged steel ball manufacturers, which have 30 years of production experience.

We also have Hi-Tech and capable production line.

Q2. In which countries are your products sold?

A: Our forged steel balls are exported to over 30 countries and regions including USA, Republic of Korea, Japan, Malaysia, Australia, Canada and South Africa, etc., well and universally received by clients. In order to better serve customers, we have set up the office in Malaysia, Chile, United States and Spain.

Q3: Are you trading company or manufacturer ?

A: We are factory.

Q4: How long is your delivery time?

A: Generally it is 5-10 days if the forged steel balls are in stock. or it is 15-20 days if the forged steel balls are not in stock, it is according to quantity.

Q5: Do you provide samples ? is it free or extra ?

A: Yes, we could offer free forged steel ball samples, you only need to pay the freight cost.

Q6: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,

balance before shippment.