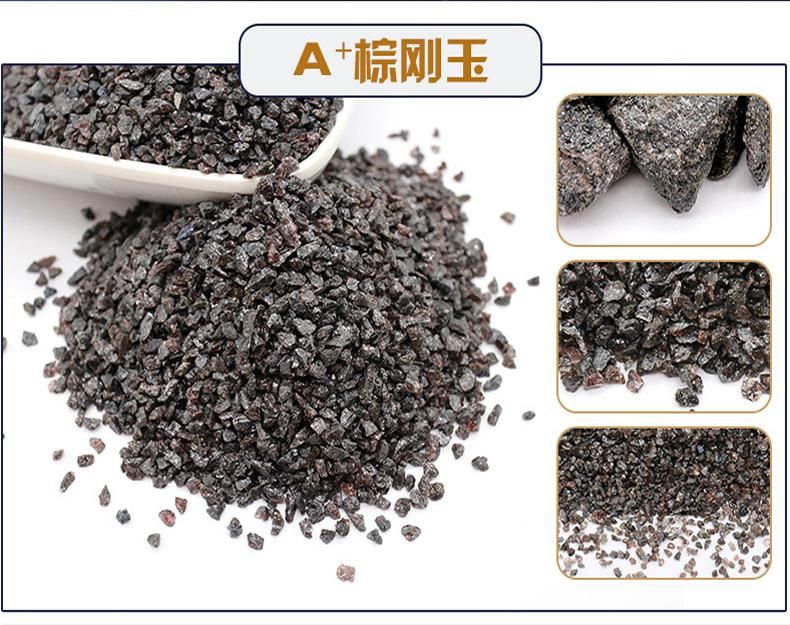

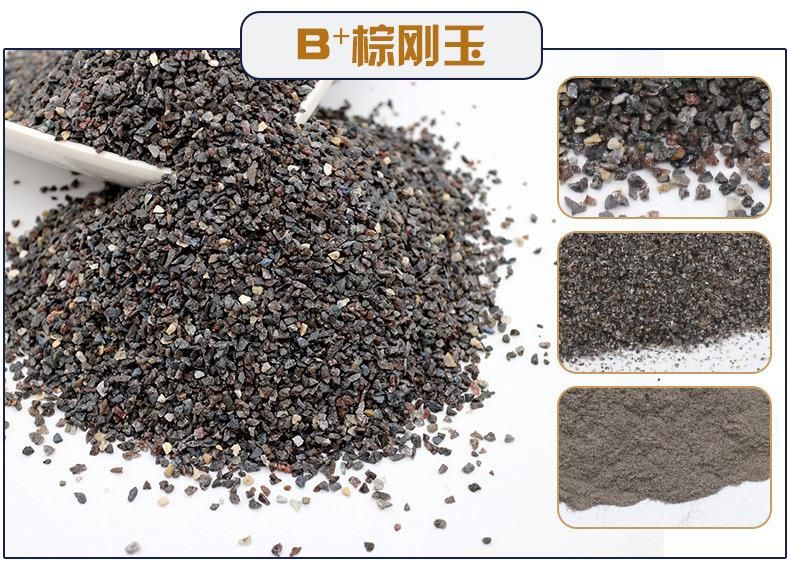

Grits Fepa 20# Brown Fused Alumina for Cutting Discs Abrasive

Dengfeng Sweet Abrasives Co., Ltd.- Natural Abrasive Type:Natural Corundum

- Artificial Abrasive Type:Corundum Abrasives

- Application:Machinery

- Function:Surface Deburring

- Source:Natural Abrasives

- Particle Size:Abrasive

Base Info

- Model NO.:1TP-05

- Hardness:Superabrasive

- Certificate:ISO9001:2008, MSDS, SGS .CE

- Hardness Moh:Vickers Harness: 2100 Hv Mohs: 9

- Bulk Density:F12#-F220# 1.98-1.68g,cm3

- Abrasives Size:24#-220# & F12-F1500

- Refractory Size:0-10mm 3-5mm

- Different Process:Fixed Furnace & Dumping Furnace

- Superiority:Have Our Own Factory , Plant

- Al2O3:95%Min. Sio2 1%Max

- Fe2o3:0.3%Max. TiO2 2.0-2.8%

- Cao:0.45% Max.

- Material:Aluminium Oxide Al2O3

- True Specific:3.97g,cm3

- Usage:for Bonded Abrasives Like Cutting Discm Grinding W

- High Light:Fepa Brown Fused Alumina

- Transport Package:25kgs Bags +Ton Bag or Pallet

- Specification:F16-F320

- Trademark:Swt

- Origin:Dengfeng. China

- HS Code:281810000

- Production Capacity:1000 Tons,Month

Description

Supply Capacity & Application

BFA grit: F12#-F220# for abrasives and sandblasting: 1000 mt per MonthBFA section sand 0-1mm, 1-3mm, 3-5mm, 200 mesh, 325 mesh for refractory: 1000 mt per MonthBrown Aluminum oxide grits especially F 20#, 24#, 30#, 36#, 46#, 60#, 70#, 80# Is applicable for Bonded abrasives.

Vitrified Bonded abrasives and resin bonded abrasives. Like grinding wheels, cutting discs, etc.

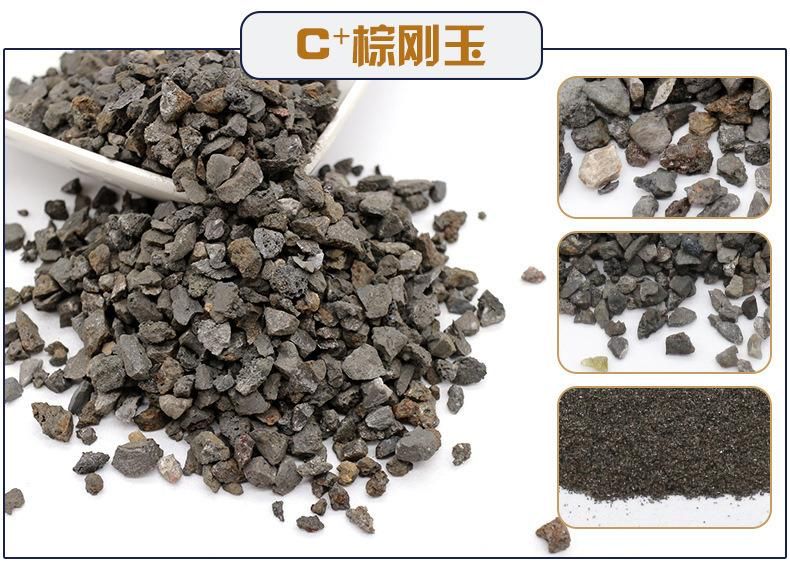

What Is Difference Between Tilting Furnace Melted BFA & Fixing Furnace Melted BFA ?

Ball Milling & Barmac Process?

1. Tilting furnace process affects SiO2, SiO2 <1% by Tilting furnace, SiO2 <1.5% is by fixed furnace.

2. Barmac affects the density, the grain shape is rounder & the density is greater than ball milling

3. The Tilting furnace made BFA has high Al2O3 content

4. The corundum has good toughness & more suitable for abrasive products by dumping furnace process

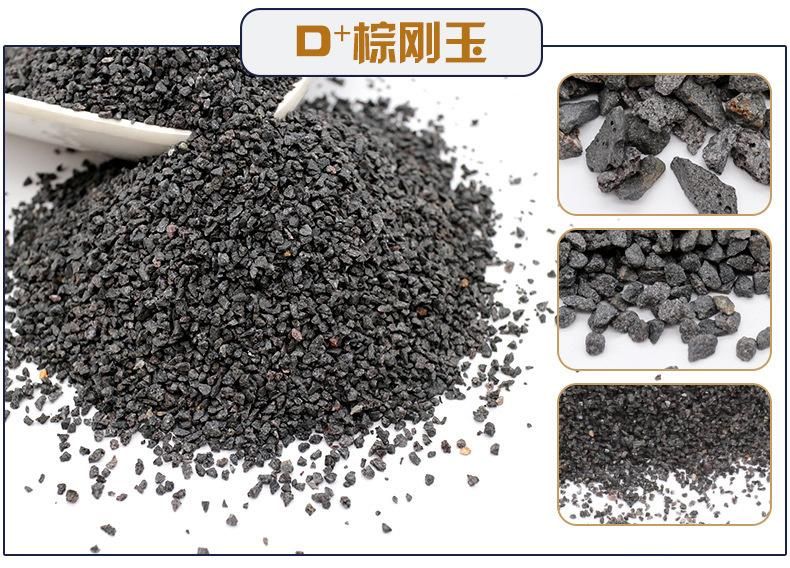

The difference between F-grit & P-grit Abrasive grains:

F-grit is more suitable for bonded abrasive tools.

P-grit is more suitable for coated abrasive tools. It is with a closer tolerance size distribution, lower density, and better self-sharpening ability than non-P-grit abrasives, which means that they offer a more consistent surface finish.

Grit size: 16#, 20#, 24#, 30#, 36#, 46#, 54#, 60#, 80#, 100#, 120#, 150#, 180#, 220#

Micropowder: 240#, 280#, 320#, 360#, 400#, 500#, 600#, 800#, 1000#, 1200#, 1500#, 2000#

Refractory Grit size:1-0mm, 3-1mm, 5-3mm, 5-8mm, -200mesh, -240mesh, -320mesh.

Main Features of Brown Fused Alumina

- High Hardnes

- Good toughness

- Chemical stability

- Iron Free

Main Applications of Brown Fused Alumina

- Make resin cutting discs,cremic grinding wheels

- Make coated abrasives such as sand belts, sand paper,flap wheels, fiber wheels...

- Blasting Media

- High grade refractories

- Anti-slip resistant materials

Packaging & Shipping

1. 1 ton bags in container, 25 MT/20'FCL.

2. 25kg bags in container, 25 MT/20'FCL

3. 25kg bags in ton bags, then in container, 25 MT/20'FCL

4. as the customer' request.

Why Choose us?

1) 20 years abrasive industry experiences

2) Direct Factory supply & Fixed abrasive sources

3) On-site inspection in factory for each shipment

4) Samples tests each lot in Zhengzhou Research Institute for Abrasives& Grinding Co., Ltd

Our Brown fused alumina grit has been exported to Japan, India, Israel, Russia, Poland etc.

Pls send me email to get Brown fused alumina datasheet /samples and quotation…