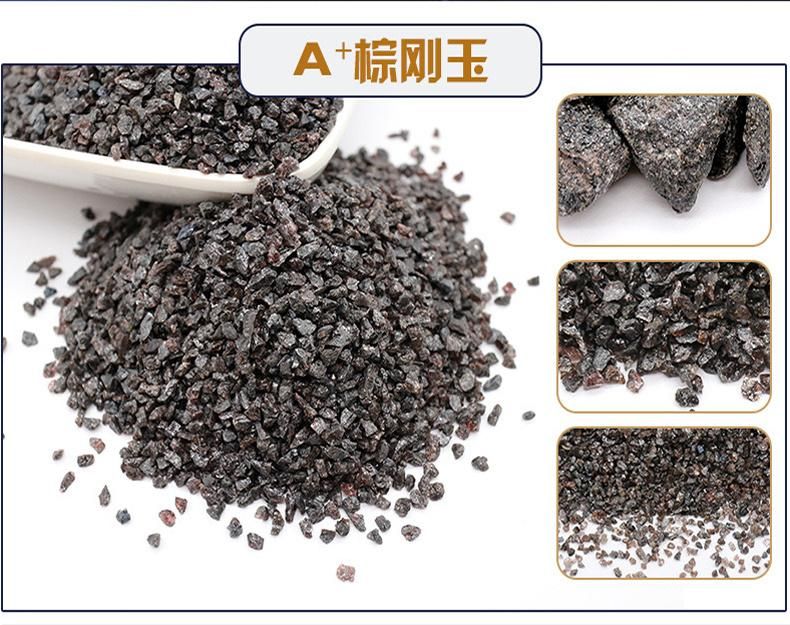

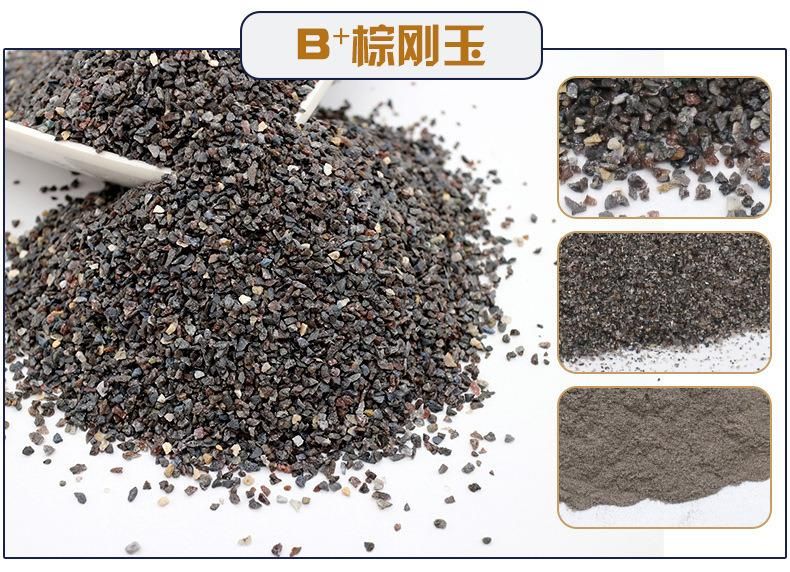

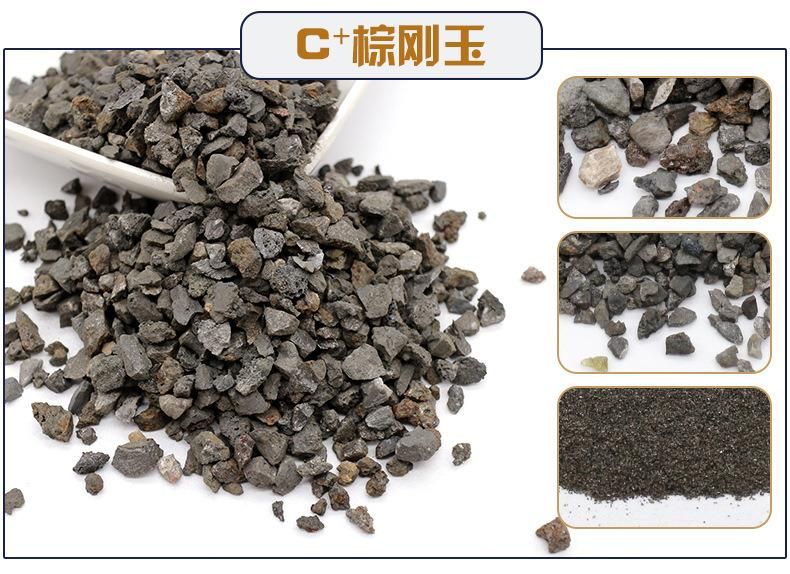

1 - 3mm / 3 - 5mm Brown Fused Alumina for Refractories Castables Refractory Bricks

Dengfeng Sweet Abrasives Co., Ltd.- Natural Abrasive Type:Natural Corundum

- Artificial Abrasive Type:Corundum Abrasives

- Application:Machinery

- Function:Surface Deburring

- Source:Artificial Abrasives

- Particle Size:Abrasive

Base Info

- Model NO.:J-O2

- Hardness:Superabrasive

- Al2O3:70-95%

- Bulk Density:1.75-1.95g,cm3

- Abrasive Size:24#-220# & F12-F1500

- Refractory Size:0-1mm, 1-3mm, 3-5mm

- Hardnes:>9 Mohs

- Sio2:1.5-5.5%

- Fe2o3:0.3-5.0%

- TiO2:1.5-3.85%

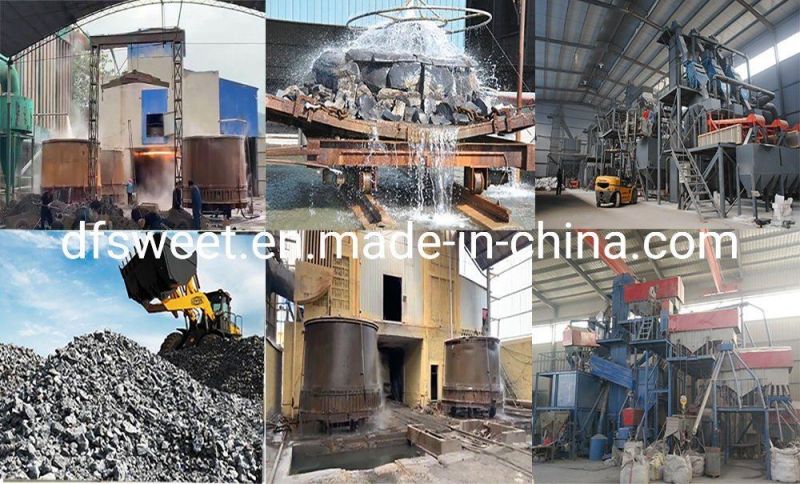

- Different Process:Fixed Furnace & Dumping Furnace

- Superiority:Have Our Own Factory , Plant

- Certificate:ISO9001:2008, MSDS, SGS .CE

- Transport Package:25kg,Bag or 1000kg,Bag, According to Your Request

- Specification:F12-F220, 24#-220#, 0-1mm, 1-3mm, 3-5mm, 5-8mm

- Trademark:Swt

- Origin:Dengfeng, Henan

- HS Code:2818101000

- Production Capacity:1000 Ton Per Month

Description

(P100-P150)

(P180-P220)

Supply Capacity

Brown Aluminum oxide section sand 0-1mm, 1-3mm, 3-5mm, 5-8mm is applicable for

Refractories, castables, refractory bricks

Brown aluminum oxide is of high purity, good crystallization, strong fluidity, low coefficient of linear expansion, high temperature resistance and corrosion resistance.

Widely used in the manufacture of advanced refractory materials:

- Castables,

- Refractory bricks,

- Ramming materials,

- Skateboards,

- Steel sliding nozzles,

- Ladle,

- Furnace linings,

- Smelting rare metals,

- Special alloys,

- Ceramics,

- Linings for ironmaking blast furnaces ( Wall and tube),

- Physicochemical utensils,

- Spark plugs,

- Heat-resistant anti-oxidation coating.

In the application process, it has the characteristics of no explosion, no powdering and no cracking.

Note: Special requirement on chemical composition can be satisfied through discussion.

What Is Difference Between Tilting Furnace Melted BFA & Fixing Furnace Melted BFA ?

Ball Milling & Barmac Process?

1. Tilting furnace process affects SiO2, SiO2 <1% by Tilting furnace, SiO2 <1.5% is by fixed furnace.

2. Barmac affects the density, the grain shape is rounder & the density is greater than ball milling

3. The Tilting furnace made BFA has high Al2O3 content

4. The corundum has good toughness & more suitable for abrasive products by dumping furnace process

The difference between F-grit & P-grit Abrasive grains:

F-grit is more suitable for bonded abrasive tools.

P-grit is more suitable for coated abrasive tools. It is with a closer tolerance size distribution, lower density, and better self-sharpening ability than non-P-grit abrasives, which means that they offer a more consistent surface finish.

Grit size: 16#, 20#, 24#, 30#, 36#, 46#, 54#, 60#, 80#, 100#, 120#, 150#, 180#, 220#

Micropowder: 240#, 280#, 320#, 360#, 400#, 500#, 600#, 800#, 1000#, 1200#, 1500#, 2000#

Refractory Grit size:1-0mm, 3-1mm, 5-3mm, 5-8mm, -200mesh, -240mesh, -320mesh.

Packaging & Shipping

1. 1 ton bags in container, 25 MT/20'FCL.

2. 25kg bags in container, 25 MT/20'FCL

3. 25kg bags in ton bags, then in container, 25 MT/20'FCL

4. as the customer' request.

Why Choose us?

1) 20 years abrasive industry experiences

2) Direct Factory supply & Fixed abrasive sources

3) On-site inspection in factory for each shipment

4) Samples tests each lot in Zhengzhou Research Institute for Abrasives& Grinding Co., Ltd

Our Brown fused alumina grit has been exported to Japan, India, Israel, Russia, Poland etc.

Pls send me email to get Brown fused alumina datasheet /samples and quotation…