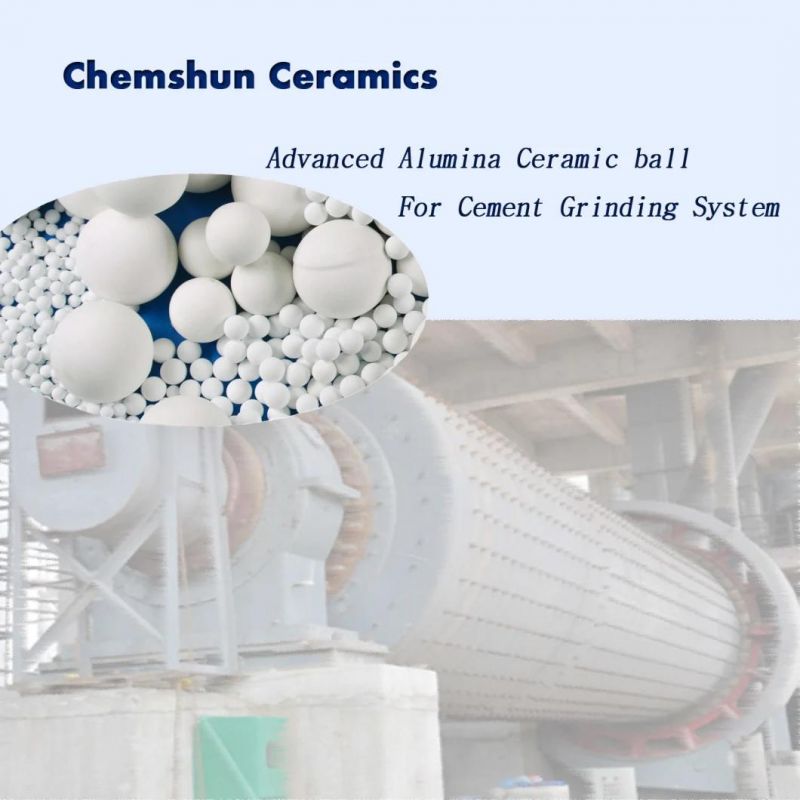

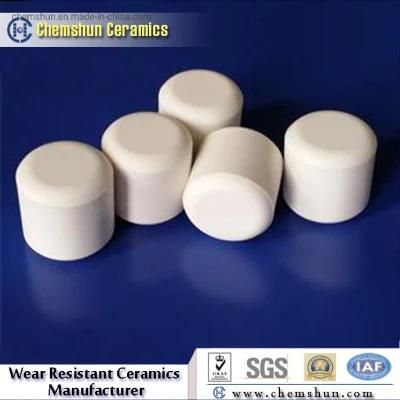

Alumina Oxide Ceramic Rods as Grinding Materials

Pingxiang Chemshun Ceramics Co., Ltd.- Material:Alumina

- Content:>90%

- Usage:Construction, Machinery, Chemical, Petroleum, Grind, Refractory Material, Wet Grinding or Dry Grinding

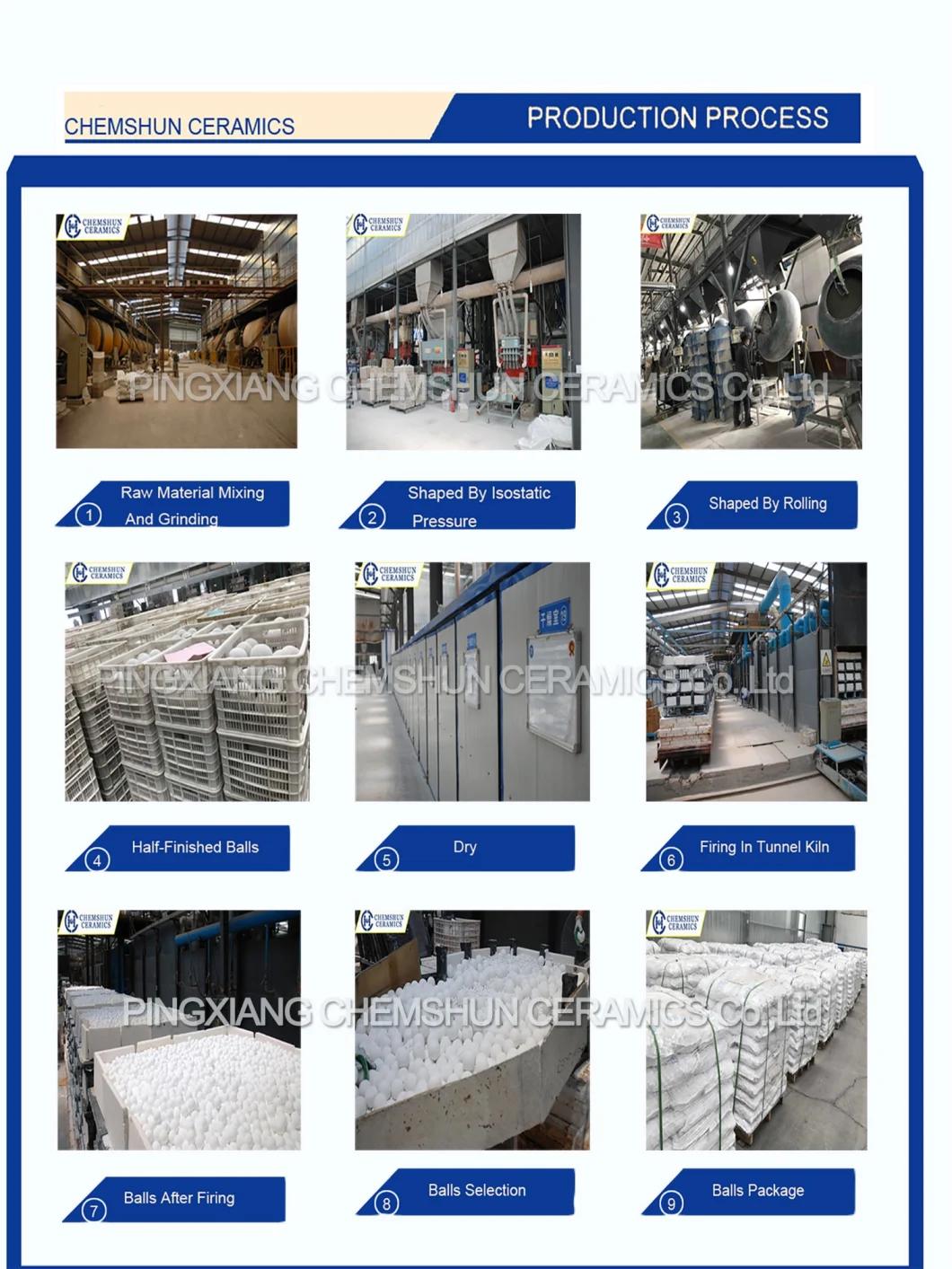

- Processing Type:Isostatic Pressing Type

- Size:Middle

- Color:White

Base Info

- Model NO.:chemshun ceramics

- Customized:Customized

- Product Name:High Alumina Ceramic Cylinder

- Raw Material:Australia Alumina Powder

- Abrasion Loss:Very Low

- Main Market:Italy

- Export Markets:Global

- Al2O3:95% Alumina

- Density:>3.68g,cm3

- Size(mm):D31xh31.5 with Chamfer

- Suitable for Grinding:Zirconium Silicate,Kaolin Clay,Feldspar

- OEM:Acceptable

- Transport Package:PE Bag+Pallet

- Specification:D31xH31.5mm

- Trademark:Chemshun

- Origin:China

- HS Code:69091200

- Production Capacity:350ton,Month

Description

Basic Info.

Model NO. chemshun ceramics Customized Customized Product Name High Alumina Ceramic Cylinder Raw Material Australia Alumina Powder Abrasion Loss Very Low Main Market Italy Export Markets Global Al2O3 95% Alumina Density >3.68g/cm3 Size(mm) D31xh31.5 with Chamfer Suitable for Grinding Zirconium Silicate,Kaolin Clay,Feldspar OEM Acceptable Transport Package PE Bag+Pallet Specification D31xH31.5mm Trademark Chemshun Origin China HS Code 69091200 Production Capacity 350ton/MonthProduct Description

Alumina Oxide Ceramic Rods as Grinding MaterialsAlumina Grinding Cylinder block is used as grinding media for ceramic body and glaze preparation.

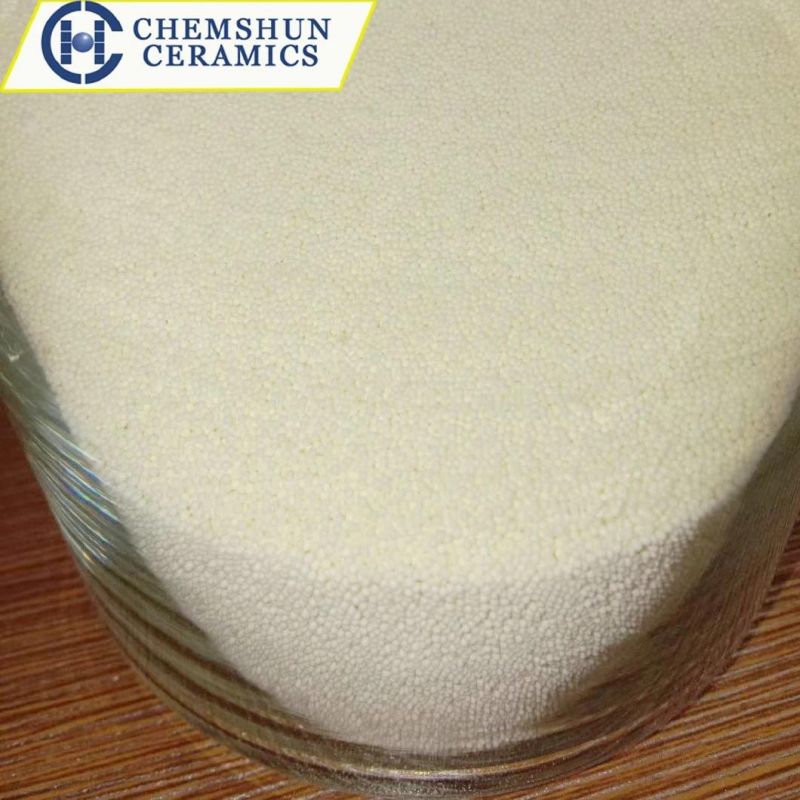

It's high purity and low abrasion loss make it to be suitable for both wet and dry superfine

grinding of alumina, zirconium silicate, glaze, kaolin clay, quartz, feldspar, inks and ceramics

in ball mill.

Technical Data

Item | 95% AL2O3 Series |

| Alumina Content(%) | ≥95 |

| Density (g/cm3) | ≥3.68 |

| Moh's Hardness (Mohs) | 9 |

| Water Absorption (%) | ≤0.01 |

| Self-wear Loss | 0.06‰ |

Product | Diameter (mm) | Height(mm) |

| Cylinder(with chamfer ) | 31±0.5 | 31.5±0.5 |

1. Made by Australia alumina powder, the abrasion loss is much better than other grinding cylinder which made by normal Chinese alumina powder.

2. The high density and low abrasion loss make the quality is confirmed and accepted by the Italian famous big company.

3.The chamfer makes the edge more smooth to be better for grinding.

4.The high purity raw material and technology keep the media in the best to wear the abrasion.

5. The high quality keep the grinding cylinder to grind time longer than others grinding media.