600L Deburring Parts Deburring Sheet Metal Edge Polishing Scratches out of Stainless Steel

Zhejiang Humo Polishing Grinder Manufacture Co., Ltd.- Type:Vibratory Finishing Machine

- Power Source:Electricity

- Object:Parts

- Application:Metal Deburring Polishing

- Disc(Wheel) Type:Round

- Material:Metal

Base Info

- Model NO.:LZG

- Working Style:Shaking

- Disc Diameter:Customize

- Variable Speed:With Variable Speed

- Noise Cover:Airtec

- Control Box:Standing on The Floor or Hang on The Wall

- Speed Converter Brand:Bosch Rexroth

- Power:5.5 Kw or 7.5 Kw

- PU Lining Thickness:20mm

- Weight:1500 Kg

- Size:1800*1800*1200mm

- Transport Package:Wooden Box

- Specification:600L

- Trademark:HUMO

- Origin:Zhejiang, China

- HS Code:84639000

- Production Capacity:5000

Description

Basic Info.

Model NO. LZG Working Style Shaking Disc Diameter Customize Variable Speed With Variable Speed Noise Cover Airtec Control Box Standing on The Floor or Hang on The Wall Speed Converter Brand Bosch Rexroth Power 5.5 Kw or 7.5 Kw PU Lining Thickness 20mm Weight 1500 Kg Size 1800*1800*1200mm Transport Package Wooden Box Specification 600L Trademark HUMO Origin Zhejiang, China HS Code 84639000 Production Capacity 5000Product Description

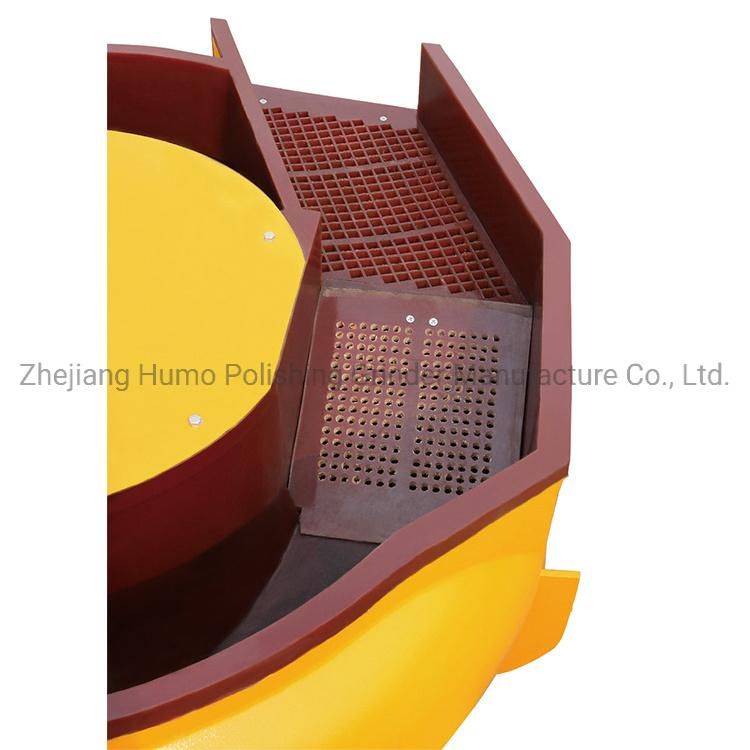

Curved wall bowl vibratory finishing machine with separating unitOur vibratory polishing machines LZG (A) are suitable for deburring and metal polishing of aluminum, brass, copper, stainless steel, and iron workpieces such as machined parts, injection molding parts, stamping parts, and die casting parts. In the mass finishing process, a container consisting of the workpieces and tumbling media is subjected to a controlled gyratory vibration. The vibration causes the tumbling media and workpieces to rub against each other, resulting in a polished look. Vibratory deburring is one of the most cost-effective surface treatment processes as it requires minimal or no labor. The unload flap and separation screen allows quick separation of workpieces from the tumbling media.

Vibratory Polishing Machine Feature:

- Digital process timer

- Low profile design

- Wide opening for big size parts

- Stress relieved and enhanced with blasting

- Default manual parts media separation

- Extended separation deck

- Wear resistant PU lining from Dow Chemicals

Vibratory Polishing Machine Optional Items:

- Noise Cover

- Compound Dosing Pump

- Pneumatic board control

- Variable Frequency Drives

- Control box standing on the floor or hang on the wall

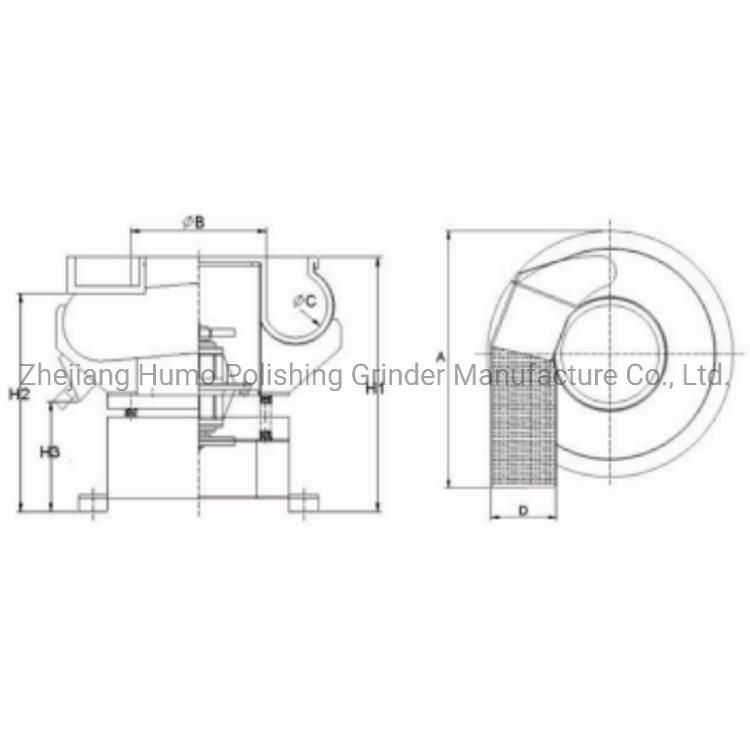

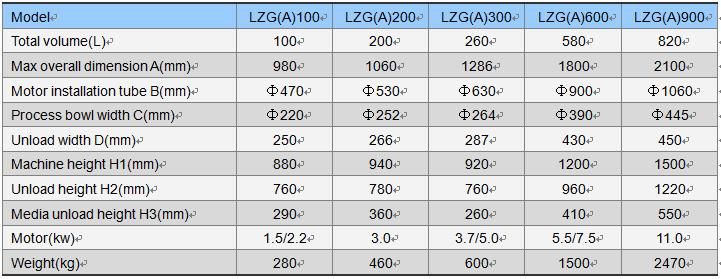

Vibratory Polishing Machine Technical Drawing:

| Model | Total volume (L) | Max overall dimension A(mm) | Motor installation tube B(mm) | Process bowl width C(mm) | Unload width D(mm) | Machine height H1(mm) | Unload height H2(mm) | Media unload height H3(mm) | Motor (kw) | Weight (kg) |

| LZG(A) 600 | 580 | 1800 | φ900 | φ390 | 430 | 1200 | 960 | 410 | 5.5/7.5 | 1500 |

Vibratory Polishing Machine Technical Data:

Vibratory Finishing Equipment Optional settings:

FAQ:

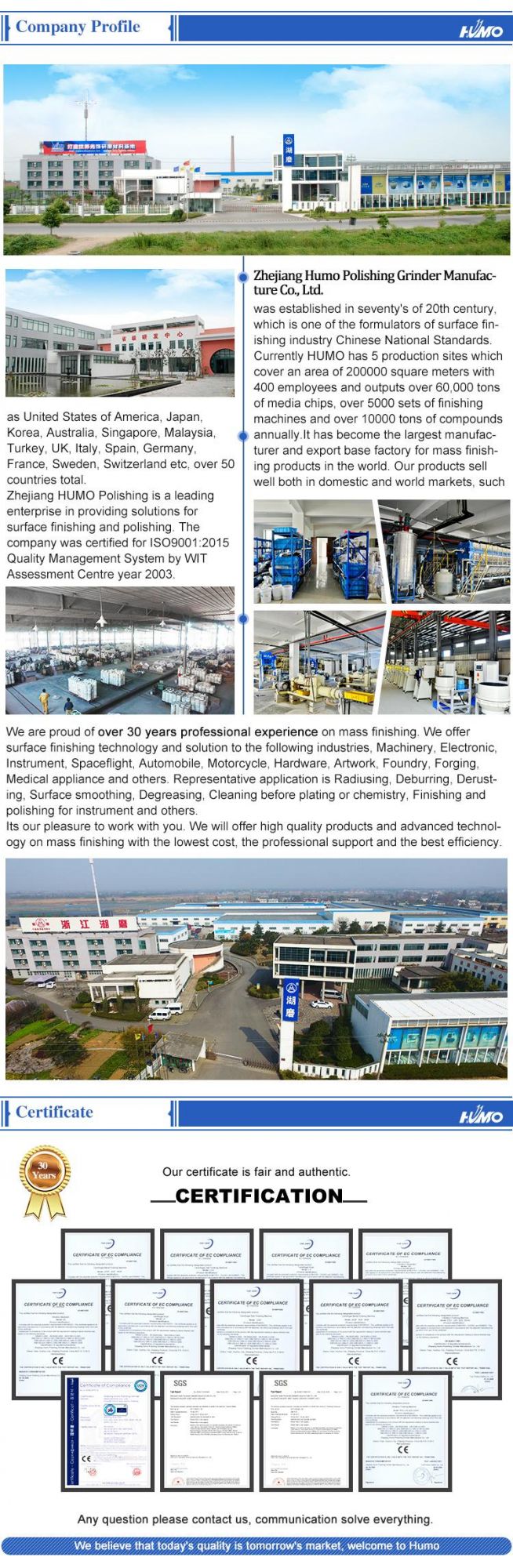

Q: How is HUMO ?

Zhejiang HUMO Polishing Grinder Manufacture Co., Ltd. is famous Top 3 brand mass finishing equipment and consumables manufacturer of China, has:

- 25 years: vibratory finishing machines and tumbling media manufacturer experience.

- 200000 square meters factory

-more than 500 employees

-outputs over 60,000 tons of media chips,over 5000 sets of finishing machines and over 10000 tons of compounds annually

-our products sell well both in domestic and world markets, such as United States of America, Japan, Korea, Australia, Singapore, Malaysia, Turkey, UK, Italy, Spain, Germany, France, Sweden, Switzerland etc, over 50 countries total

Q: What Certifications do you have?

ISO9001, CE, certifications etc. 100% quality check, and testing before shipment.

Q: What is the equipment warranty?

1 year warranty for all Machinery equipment

Q: What is your Payment method?

Accept payment via T/T (Bank transfer), Western Union, Money Gram;

Q: What is your Minimum order amount?

For machine minimum order is 1 PCS. For tumbling media minimum order is 1000kg or 2000 lbs as one pallet.

You can ship less amount of media if ship with the machine.

Sample order is allowed to ship less amount of tumbling media

Q: What is your way of packaging?

Fermentation wooden pallets for media, 1000kg per pallet, 25kg/plastic bag

Wooden box for equipment and compound

Q: How long is your production time?

15 working days for sample order;

20-25 working days for bulk order.

Emergency order can be fulfilled in a week

Q: What is the Shipping Way?

20-30 days by sea to your nearest seaport

2-5 days by air to your nearest airport

3-5 days by express to your doorstep

Q: What is the nearest Port:?

Shanghai, Ningbo and Yiwu are the closest port.