High Quality Zirconia Ceramics Grinding Media Balls for Mining Industry

Pingxiang Chemshun Ceramics Co., Ltd.- Material:Zirconia

- Content:>90%

- Usage:Grind

- Processing Type:Isostatic Pressing Type

- Size:Small

- Color:White

Base Info

- Model NO.:CS-60

- Customized:Customized

- Item:Zirconia Grinding Balls

- Materials:Zirconia

- Type:High-Zironia

- Diameter:1mm-70mm

- Grinding Situation:Dry Grinding, Wet Griding

- Feature:High Hardness, High Density and Anticorrosion

- Application:Ball Mill, Pebble Mill

- Field:Ceramic, Metallurgy, Glass, Porcelain, Enamel

- OEM:Accept

- Transport Package:by Bags, Then Fasten on Pallet.

- Specification:D1~D70mm

- Trademark:pingxiang chemshun ceramics

- Origin:P. R. China

- HS Code:69091200

- Production Capacity:10000 Tons,Year

Description

Basic Info.

Model NO. CS-60 Customized Customized Item Zirconia Grinding Balls Materials Zirconia Type High-Zironia Diameter 1mm-70mm Grinding Situation Dry Grinding, Wet Griding Feature High Hardness, High Density and Anticorrosion Application Ball Mill, Pebble Mill Field Ceramic, Metallurgy, Glass, Porcelain, Enamel OEM Accept Transport Package by Bags, Then Fasten on Pallet. Specification D1~D70mm Trademark pingxiang chemshun ceramics Origin P. R. China HS Code 69091200 Production Capacity 10000 Tons/YearProduct Description

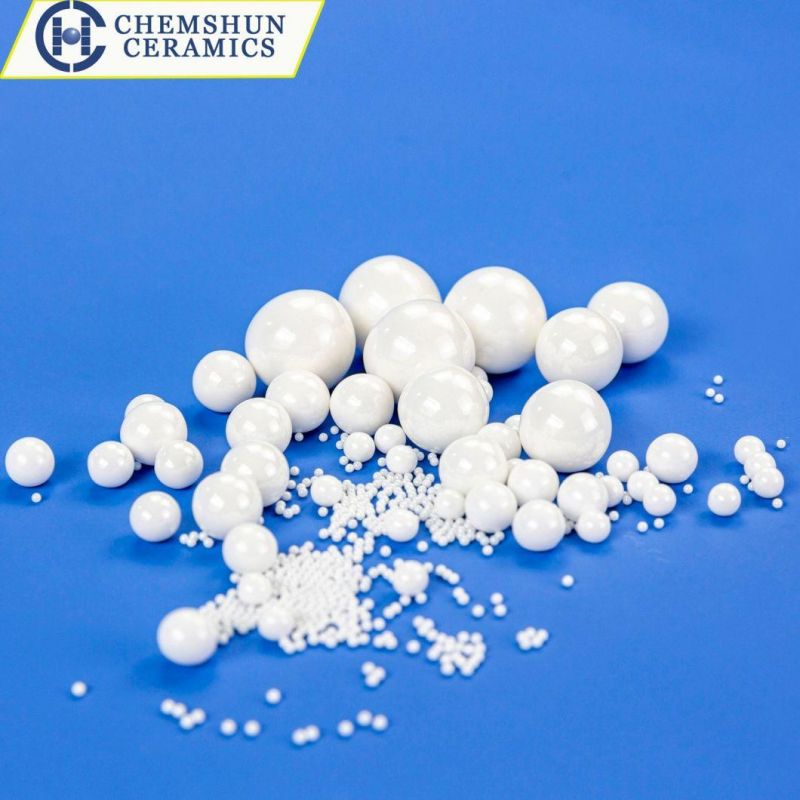

High Quality Zirconia Ceramics Grinding Media Balls for Mining IndustryCS-60 series Zirconia-Y grinding media

Description:

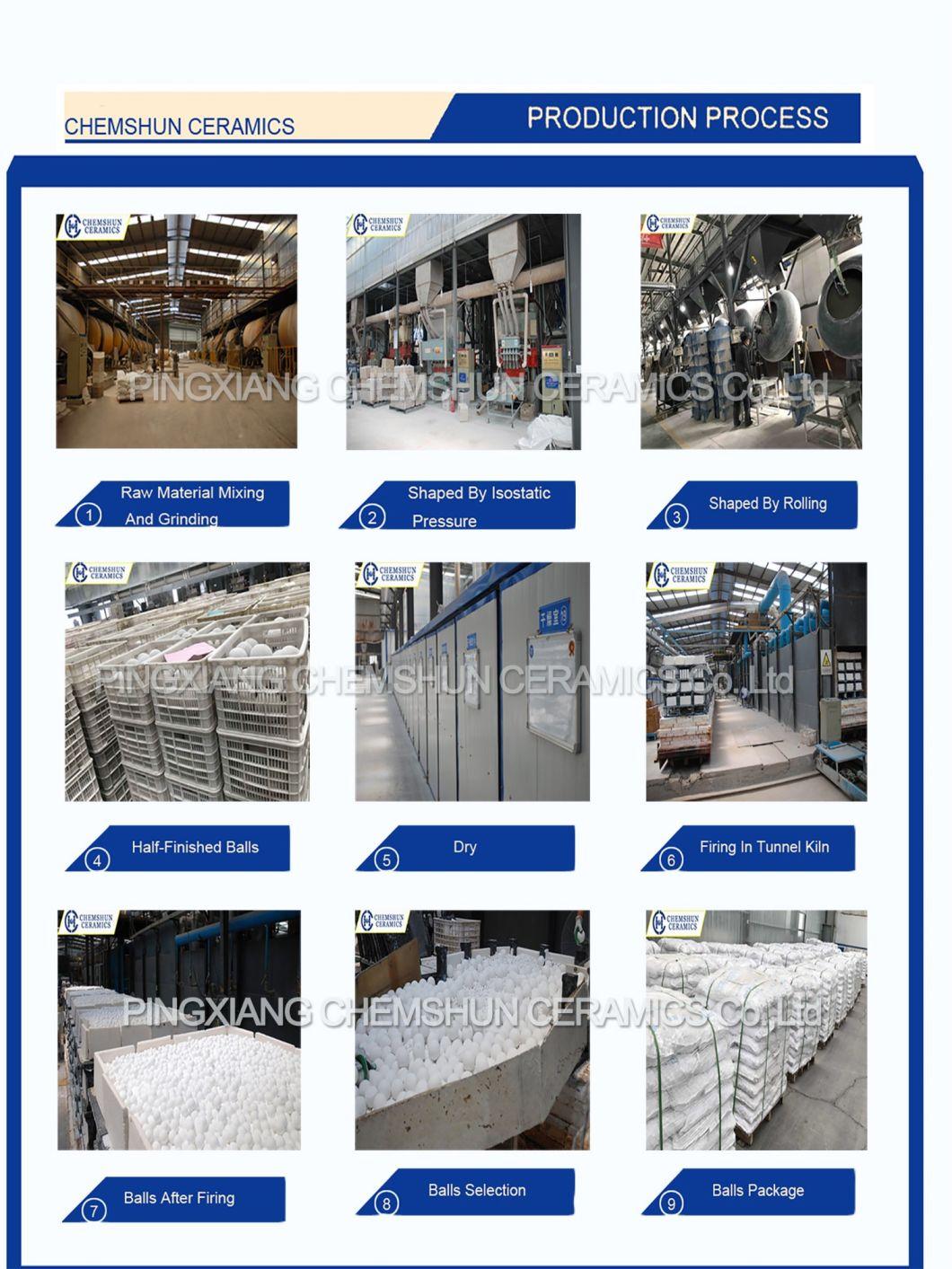

Chemshun Ceramics is a professional ceramic grinding media manufacturer. Our CS-60 series Zirconia-Y grinding media (shape as ceramic grinding beads , grinding balls or grinding cylinder) ,

Appearance:

Feature:

the main chemical composition as ZrO2:95%, Y2O3:5%, have the following benefits:

1.High density( 5.9~6.1 g/cm3 ) and it's ideal for high energy mills, maximizing throughput and productivity.

2.Superior strength and High hardness( up to 1300~1400 vickers hardness ) achieve the maximum milling results at minimum product contamination rates and reducing the energy cost.

3.Minimum of wear and tear on equipments and best grinding media.

4.Excellent stability, strong acid resistance and alkali proof.

5.Consistent particle small size ( Diameter range 0.1~20mm ) and no porous and irregular shape problems ( Roundness >93% ). We can customized for customers.

Technical data :

| Properties | Unit | Data |

| Composition | wt% | 95% ZrO2 5% Y2O3 |

| Specific density | g/cm3 | 5.9-6.1 |

| Moh's hardness | grade | > 9.0 |

| Elastic modulus | Gpa | 205 |

| Thermal conductivity | W/m.k | 3 |

| Crushing load | Kn | >20 (Dia 7 mm) |

| Fracture toughness | Mpa m1/2 | 7-10 |

| Grain size | µm | <0.5 |

| Thermal expansion Coefficient (20-400 ºC) | 10*10-6/ºC(20-400) | 11 |

| Size range of beads Size range of cylinder | Mm Mm | 0.1--55 6---40 |

Other grinding balls:

We also have others ceramic mill ball series:

Low-density series : CS26 with unmatched economic and performance advantage in fine and ultra-fine grinding process of soft mineral materials with low slurry density.

Middle density series : CS32, CS36, CS38, CS40, which widely used in the grinding mill of mining and minerals and suitable for hard minerals, high density slurry of minerals. The series media improve cost efficiency of customer.

High density series : CS52, CS60, CS62 with the best grinding, mixing and dispersing efficiency. This zirconia-based grinding medias is the optimum combination of efficient and cost-effective products to enhance productivity and quality.

We have experts team understand your needs and supply the engineered great ceramic grinding media for your grinding application. And We offer on-site visiting, lab testing, professional solution for you. Once you need more information welcome to contact with us