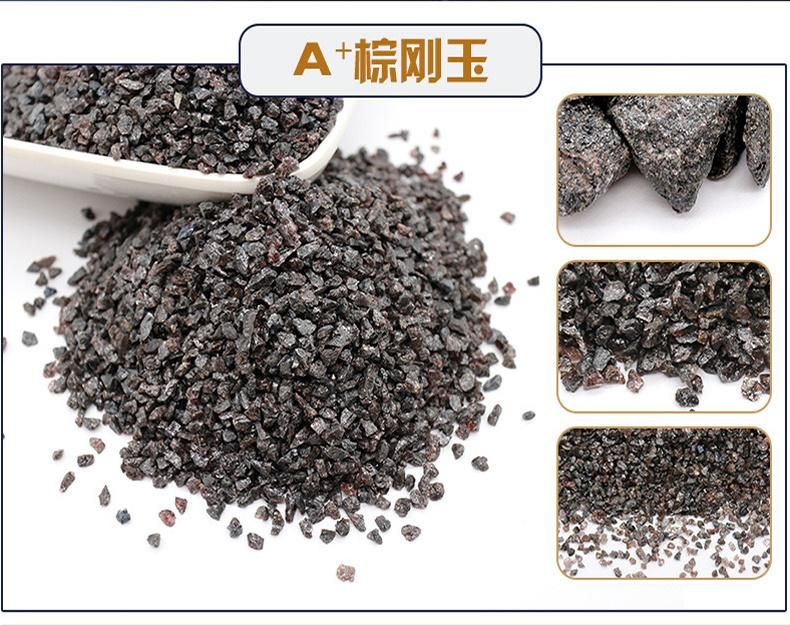

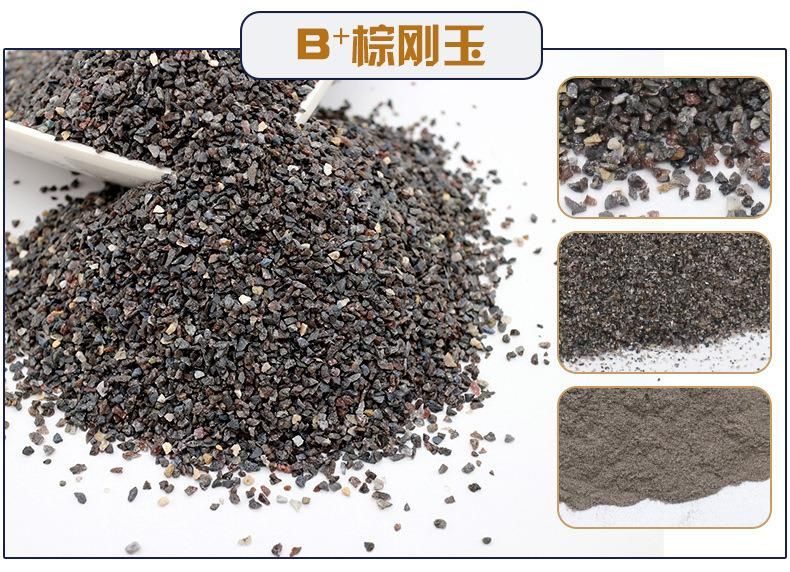

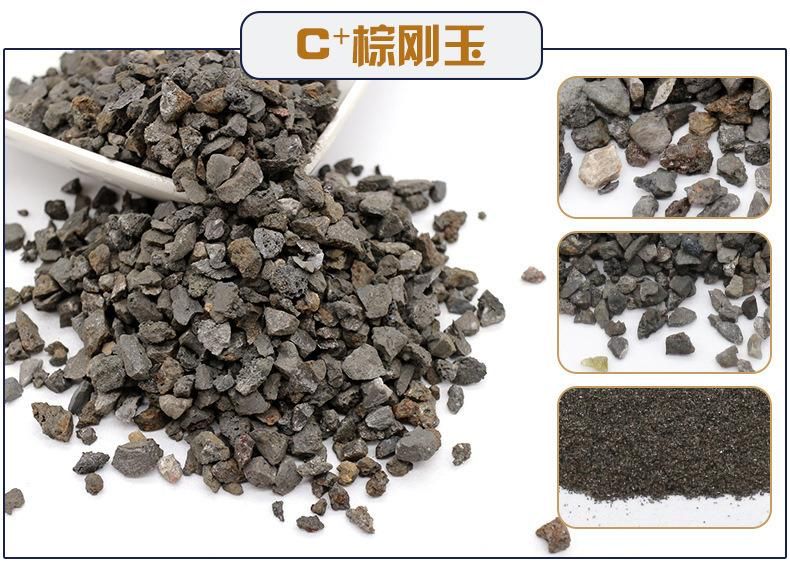

220 Mesh 2100hv F220 Al2O3 Aluminum Oxide Blasting Media

Dengfeng Sweet Abrasives Co., Ltd.- Artificial Abrasive Type:Corundum Abrasives

- Source:Natural Abrasives

- Hardness:Superabrasive

- Certificate:ISO9001, ISO14001

- Hardness Moh:Vickers Harness: 2100 Hv Mohs: 9

- Specific Gravity:3.95 g,cm3

Base Info

- Model NO.:1TP-01P0

- Usage:for Bonded Abrasives Like Cutting Discm Grinding W

- Sample:1 Kg for Free

- Bulk Density:F12#-F220# 1.98-1.68g,cm3

- Chemical Index:95%Min. Sio2 1%Max

- Fe2o3:0.3%Max. TiO2 2.0-

- High Light:Brown Fused Alumina Brown Fused Aluminum Oxide

- Superiority:Have Our Own Factory , Plant

- Different Process:Fixed Furnace & Dumping Furnace

- Transport Package:25kgs Bags +Ton Bag or Pallet

- Specification:F12-F320#, P12-P320#

- Trademark:Swt

- Origin:Dengfeng. China

- HS Code:281810000

- Production Capacity:1000 Tons,Month

Description

Supply Capacity

BFA grit: F12#-F220# for abrasives and sandblasting: 1000 mt per MonthBFA section sand 0-1mm, 1-3mm, 3-5mm, 200 mesh, 325 mesh for refractory: 1000 mt per Month

As sandblasting abrasive media

1. Less dust

Due to brown aluminum oxide's relatively high specific gravity, it produces less dust during the sandblasting process. This ensures operator health and safety and improves operator visibility.

2. High efficiency

The brown aluminum oxide abrasive grits can quickly hit the surface of the object with sharp edges and corners, it is regarded as a very fast way of sandblasting.

3. Low loss

The unique size of brown aluminum oxide ensures that more effective particles hit the surface of the object (such as 30-60 mesh sand, which can produce 11 million particles per kilogram to hit the surface of the object, while conventional slag such as 20 mesh can only produce 1 million.

4. High surface treatment quality

During the blasting process, brown aluminum oxide can penetrate deep into the caves and pits of the surface to reach the bare surface of the metal, so it can completely remove all rust, water-soluble salts and other pollutants.

Brown aluminium oxide Application -Metal surface preparation before coating

Brown aluminium oxide abrasive media is usually used for blasting pretreatment for variety of materials for preparation before coating. Such as ferrous metal, steel, Aluminium alloys, Titanium alloy, stainless steel, etc.

Sandblasting pretreatment is a very important step in coating preparation. The surface quality of the processed workpiece will directly affect the bonding strength of the surface and the coating, thereby affecting its service life.

The treatment process of surface pretreatment is mainly divided into the following three steps: surface pretreatment, surface purification and surface activation.

Sandblasting is to use brown aluminium oxide abrasive media to increase the surface roughness of the workpieces, and to increase the adhesion between the coating and the workpiece surface. At present, there are many available brown aluminium oxide abrasive specifications for sandblasting pretreatment, such asthe grit size F4#-220#, 0-1mm,1-3mm etc.. The specific abrasive specifications can be selected according to the actual situation.

Packaging & Shipping

1. 1 ton bags in container, 25 MT/20'FCL.

2. 25kg bags in container, 25 MT/20'FCL

3. 25kg bags in ton bags, then in container, 25 MT/20'FCL

4. as the customer' request.

Why Choose us?

1) 20 years abrasive industry experiences

2) Direct Factory supply & Fixed abrasive sources

3) On-site inspection in factory for each shipment

4) Samples tests each lot in Zhengzhou Research Institute for Abrasives& Grinding Co., Ltd

Our Brown fused alumina grit has been exported to Japan, India, Israel, Russia, Poland etc.

Pls send me email to get Brown fused alumina datasheet /samples and quotation…