-

Factory Direct Sell 5 Inch Honeycomb Diamond Dry Concrete Polishing Pads

50/100/200/400/800/1500/3000/BUFFSDP021004"20/ 22.233SDP021255"20/ 22.233

-

Taa Cast Steel Grit G12/G14/G16/G18/G25/G40/G50/G80/G120 for Sand Blasting

Overview Product DescriptionProduct ParametersProduct ApplicationCompany ProfileProduction processCertificationsTAA committed to the provision of high-end surface treatment equipment and solutions.It has finally realized the surface treatment industry chain from metal abrasives to

-

Deburring Polishing Milling Grinding Ceramic Media Finishing Media Polishing Media Abrasives

Basic Info. Model NO. SFP H

-

16#24#30#36# Strong and Sturdy Corn COB for Wiping Metal

Overview Product DescriptionProduct ParametersAbrasive Corn Cob Granules for oil removing / polishing / surface treatment / sandblastingDensity1.15g/ccHardness2.0-2.5 MOHFiber Content90.9Water Content8.7PH5 ~ 7Available sizesGrit No.Size micronGrit No.Size micron55000 ~ 4000161180

-

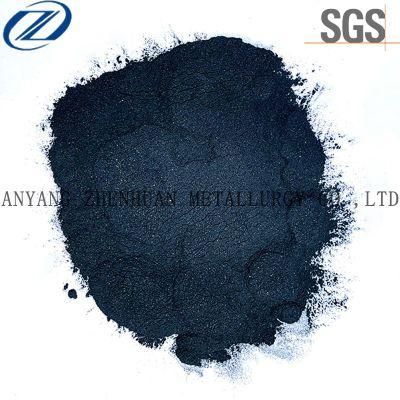

Anyang Black Silicon Carbide Powder Sic Grit

Chemical CompositionSIC(%)F.C(%)Fe2O3(%)F12-F90≥97≤0.2≤0.2F90-F120≥97≤0.2≤0.2F120-F220≥97≤0.3≤0.2F220-F240≥97≤0.3≤0.3F240-F325≥97≤0.4≤0.3F325-F500≥97≤0.4≤0.3

-

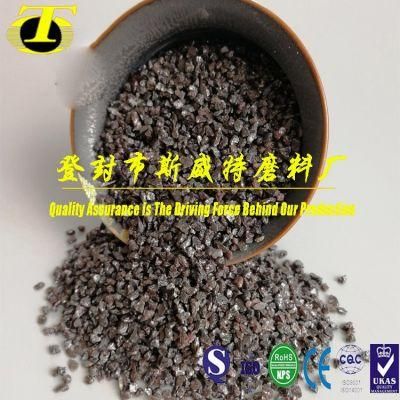

High Purity 99% White Fused Alumina / White Alumina Oxide

Grit SizeF12,F14,F16,F20,F22,F24,F30F36,F40,F46,F54,F60,F70,F80,F90F100,F120,F150,F180,F220Product StandardChina GB/T,FEPA etc.5. Packaging & Shipping1. 1 ton bags in container, 20 MT/20'FCL.2. 25kg bags in container, 25 MT/20'FCL3. 25kg bags in ton bags, then in container, 20 MT/20'FCL4. as the

-

High Grade White Alumina Oxide for Plexiglass Fog Surface Treatment

Overview Product DescriptionProduct ParametersPurposeSpecificationChemical Composition(%)Magnetic material content(%)maxAbrasives gradeAl2O3minFe2O3maxSiO2maxTiO2maxgrain12-80990.050.260.080.002390-150990.060.280.090.0021180-220990.080.300.100.0018micropowder240-400098.50.10.400.1

-

Grinding Deburring Polishing Finishing Plastic Abrasive Media

Basic Info. Model NO. PL Ha

-

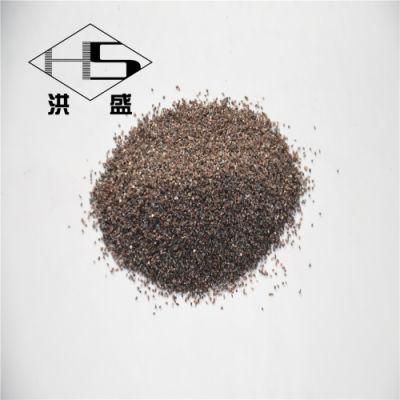

Brown Emery Grain/Grit for Sand Blasting F12-240#

Basic Info. Model NO. BFA F12-F220, 24#-220#, 0-1-3-5-8mm, 220#-8000#

-

Brown Fused Alumina Grit 400# / Emery Sand for PCB Blasting

Section sand0-1mm 1-3mm 3-5mm 5-8mm 8-12mm≥95.3≤0.3≤1.0≤2.8-25-0mm 10-0mm50-0mm 30-0mm≥95.5≤0.3≤1.0≤2.8-BFA Crude for AbrasiveFinepowder180#-0 200#-0 320#-0≥94.0≤0.4≤1.0≤3.0-Applications Brown Fused Alumina1. Bonded abrasivesVitrified Bonded abrasives and resin bo