-

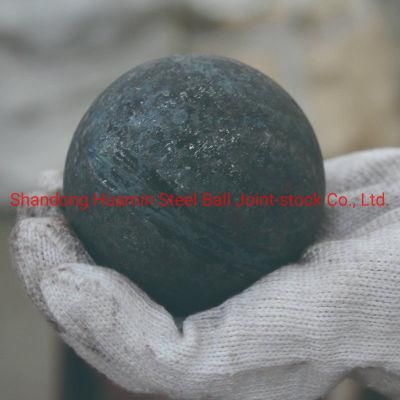

Forged Steel Grinding Ball for Mining / Abrasive Steel Balls

Product NameForged steel ballSteel ball diameterΦ 20mm -Φ 150mmMaterial Grade45#, 50Mn, 60Mn, 65Mn, B2, B3, BL, BGForged ball hardnessHRC55-66CertificationTUV ISO9001, SGSBreakage rate<1%Impact toughness>12AK.j/cm^2Heat treatmentquenching/temperingApplication AreasGrinding steel ball g

-

High Chrome Casting Grinding Ball for Mining

Basic Info. Model NO. 45#, 50Mn, 60Mn, 65Mn, B2, B3, BL, BG

-

High-Quality Ball Mill Balls After Heat Treatment

Hot rolled steel balls have the following characteristics:1. Hot-rolled steel balls have all the advantages of steel, and become high-quality ball mill balls after heat treatmentSecond, the production efficiency is high, the output is large, the rolling ball production is mechanized, and the degree

-

100mm Good Quality and Good Price Steel Grinding Media Balls China

130mm140mm150mm160mm(3¾Inch)(4 Inch)(4⅓Inch)(5 Inch)(5½Inch)(6 Inch)(6⅓Inch)3. Global Top500clients:4.The production lines for grinding steel ballsare made and designed by our expertise. And it is the first one production line for grinding rods in China in 2009.For the larg

-

Forged Carbon Grinding Steel Ball for Cement Mill

Basic Info. Model NO. B2, B3

-

Grinding Media Abrasive Ceramic Balls From Manufacturer

Producingway::cool-isostaticpressing,orbyrollingC : SizeDiameter(mm)D1-3D6/8/10/13/16/20/25D30/40D50/60/70Tolerance(±mm)0.5123

-

Forged Grinding Steel Solid Glass Ball Used in Ball Mill

Basic Info. Customized Customized

-

NameCMnSiSPCrSY-01-45#0.42-0.480.50-0.800.17-0.370.05max0.05max0.15maxSY-02-50Mn0.48-0.560.65-1.000.17-0.370.05max0.05max0.15maxSY-03-60Mn0.57-0.650.70-1.100.17-0.370.05max0.05max0.25maxSY-04-65Mn0.62-0.750.90-1.200.17-0.370.05max0.05max0.25maxSY-05-B20.75-0.850.70-0.900.17-0.350.05max0.05max0.40-0.

-

Ceramic Ball for Grinding Media From ISO Zibo Factory

92% Alumina Grinding BallAl2O3(%)92±1Fe2O3(%)<0.25SiO2(%)≤5Mohs hardness9Water absorption<0.01Bulk density(g/cm3)>3.60Wear loss(g/kgh)<1.6Crushing strength(3mm)>1050NSizeØ0.5-60mmSphericity>95%(4) Standard Dimensionø0.5-1mm, ø1.5mm, ø2mm, &osla

-

Hot Sale Forged Steel Grinding Media Ball Cast Iron Balls

≥10000Quality controlOur company Strictly sticking to the ISO9001 :2000Quality Management System Standards, we establish and perfect the quality control standards and process documents. We also dradually improve the quality assurance system. In every process from raw material entering to finished