Synthetic Diamonds for Making PDC Cutters PCD Grinding Wheels Cutting Tools

Zhengzhou Hanguang Super Hard Tools Co., Ltd.- Type:Diamond

- Classification of Diamond:Artificial

- Characteristic:High Hardness

- Characteristics of Natural Diamond:Low Thermal Expansion Rate

- Synthesis of Cubic Boron Nitride Method:Static High Pressure Direct Conversion Method

- Application:Machinery and Electronics

Base Info

- Model NO.:20,30~600,800 Mesh

- Applications:Stones, Glasses, Metals, Concrete

- Transport Package:Bottle, Bag, Carton

- Specification:20,30~600,800 Mesh

- Trademark:HG

- Origin:China

- HS Code:7105102000

- Production Capacity:200000000carats,Year

Description

HG6030/35 230/270 35/40 270/325 40/45 325/400 45/50 400/500 50/60 500/600 60/70 600/800 70/80

2. Features

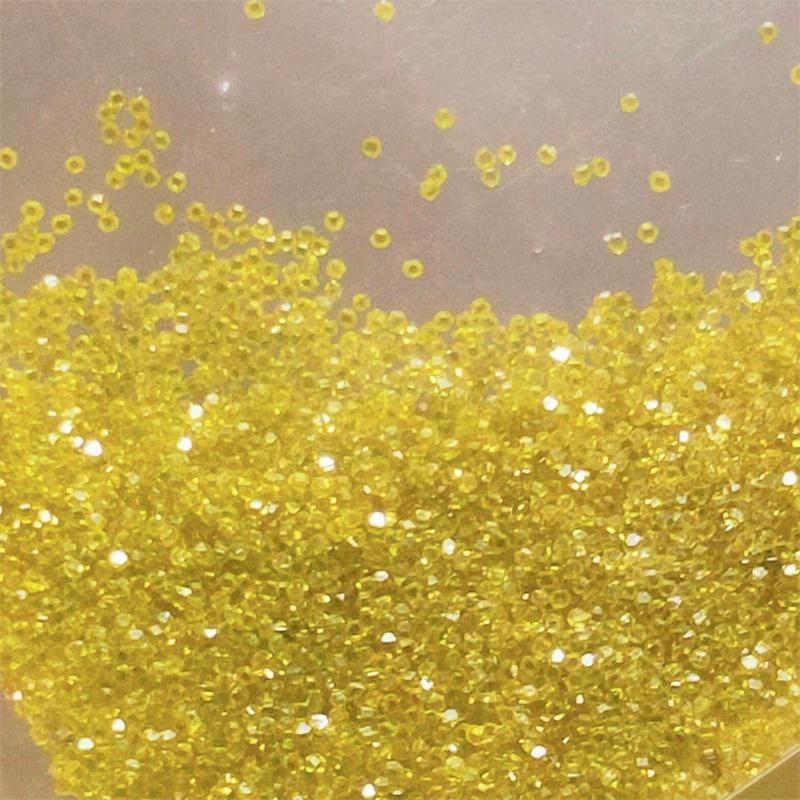

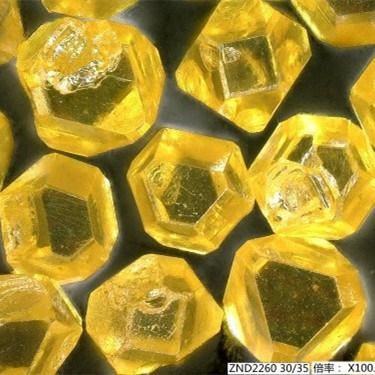

Good abrasive resistance.

Regular diamond shape.

High toughness.

Consistent quality.

High purity.

Cncentrated particle distribution.

Fast delivery.

Full sizes range .

Full grades for various applications.

3. Quality Control

(1) Laser Particle Size Analysis

As a high-precision material, the finer the particle size can be controlled, the better the performance of the diamonds in processing workpieces.

The particle size distribution of the measured particles is calculated according to the distribution of scattered light energy.

Method: Pour pthe sample into the detection cup of the laser particle size analyzer, and the system automatically tests to obtain the particle size distribution result.

(2) Impact Toughness

Through the TI test, the strength of each batch of abrasives is controlled within a narrow range, reducing large fluctuations and achieving consistent quality.

Method: Using the fixed impact number method, the sample is impacted for a certain number of times, then sieved, and the impact toughness is expressed by the percentage of the material on the sieve (unbroken material), and the value is the TI value.

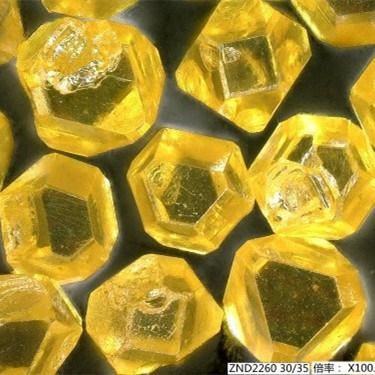

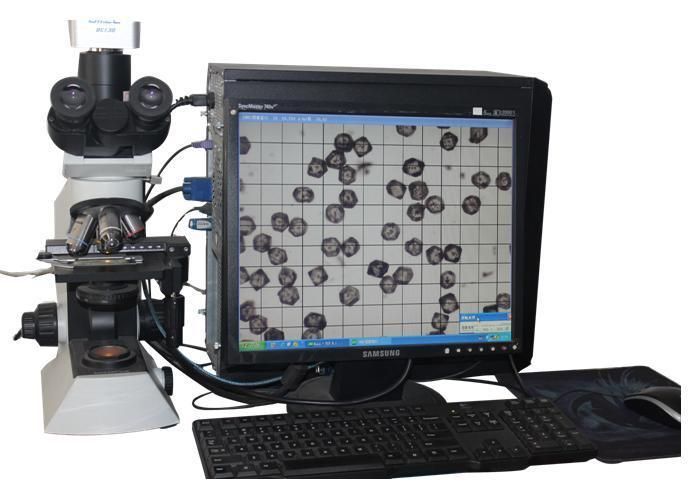

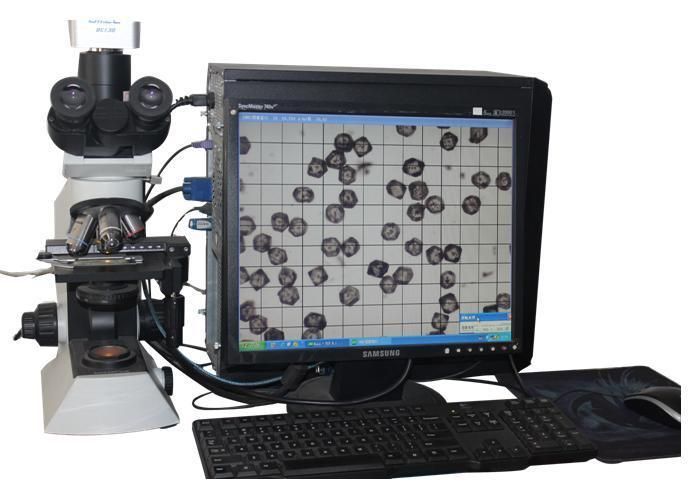

(3) Particle Morphology Analysis

By using the morphology analyzer, the particle size measurement, morphology observation and analysis of the abrasive can be carried out, and the particle size distribution of different equivalent principles (such as equal area circle, equivalent short diameter, etc.) can be given, and the particle dispersion status etc.

Methods: The samples were laid out under a microscope, and the particle size and morphology were analyzed by digital cameras and computer digital image.

(4) Thermal impact toughness

TTI is an index to measure the heat resistance of diamond, which can directly affect the life and efficiency of the tool, so TTI is very important in abrasive testing.

Method: The sample is heated at a high temperature of 1100 degrees for 10 minutes, and then the impact toughness (Ti) value of the sample is tested, and the obtained value is the value of TTI.

3. Applications

Synthetic diamonds are widely used for grinding, polishing,electroplating, sintering and so on, such as diamonds processing, tools making, construction engineering, mechanical processing, instruments, electronic industries, aviations and space field etc.

2. Features

Good abrasive resistance.

Regular diamond shape.

High toughness.

Consistent quality.

High purity.

Cncentrated particle distribution.

Fast delivery.

Full sizes range .

Full grades for various applications.

3. Quality Control

(1) Laser Particle Size Analysis

As a high-precision material, the finer the particle size can be controlled, the better the performance of the diamonds in processing workpieces.

The particle size distribution of the measured particles is calculated according to the distribution of scattered light energy.

Method: Pour pthe sample into the detection cup of the laser particle size analyzer, and the system automatically tests to obtain the particle size distribution result.

(2) Impact Toughness

Through the TI test, the strength of each batch of abrasives is controlled within a narrow range, reducing large fluctuations and achieving consistent quality.

Method: Using the fixed impact number method, the sample is impacted for a certain number of times, then sieved, and the impact toughness is expressed by the percentage of the material on the sieve (unbroken material), and the value is the TI value.

(3) Particle Morphology Analysis

By using the morphology analyzer, the particle size measurement, morphology observation and analysis of the abrasive can be carried out, and the particle size distribution of different equivalent principles (such as equal area circle, equivalent short diameter, etc.) can be given, and the particle dispersion status etc.

Methods: The samples were laid out under a microscope, and the particle size and morphology were analyzed by digital cameras and computer digital image.

(4) Thermal impact toughness

TTI is an index to measure the heat resistance of diamond, which can directly affect the life and efficiency of the tool, so TTI is very important in abrasive testing.

Method: The sample is heated at a high temperature of 1100 degrees for 10 minutes, and then the impact toughness (Ti) value of the sample is tested, and the obtained value is the value of TTI.

3. Applications

Synthetic diamonds are widely used for grinding, polishing,electroplating, sintering and so on, such as diamonds processing, tools making, construction engineering, mechanical processing, instruments, electronic industries, aviations and space field etc.