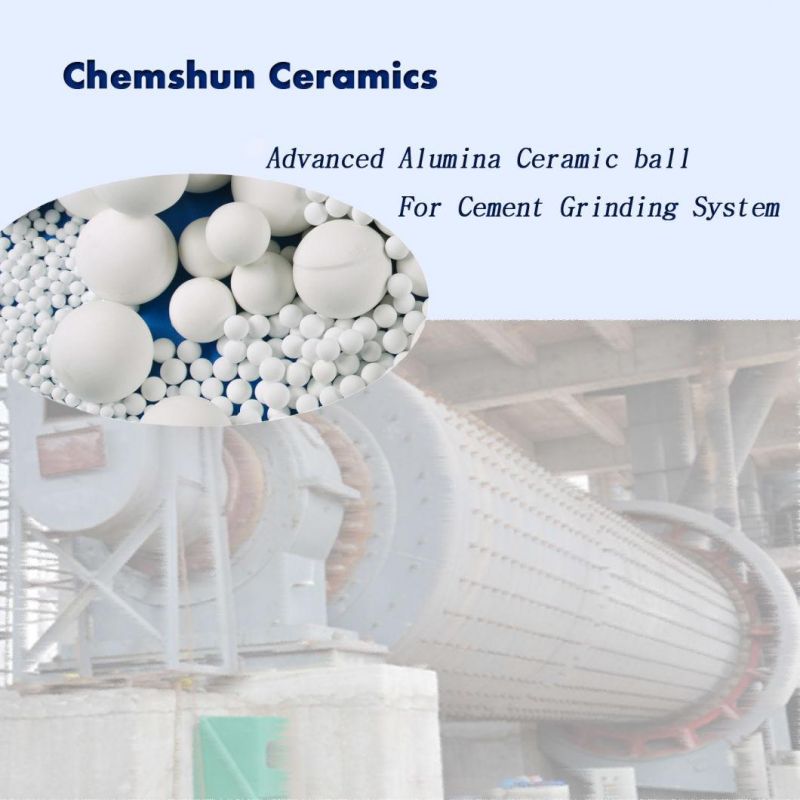

95% Al2O3 Alumina Ceramic Balls for Grinding Mines and Minerals Processing

Pingxiang Chemshun Ceramics Co., Ltd.- Material:Ceramics

- Content:>90%

- Usage:Grind

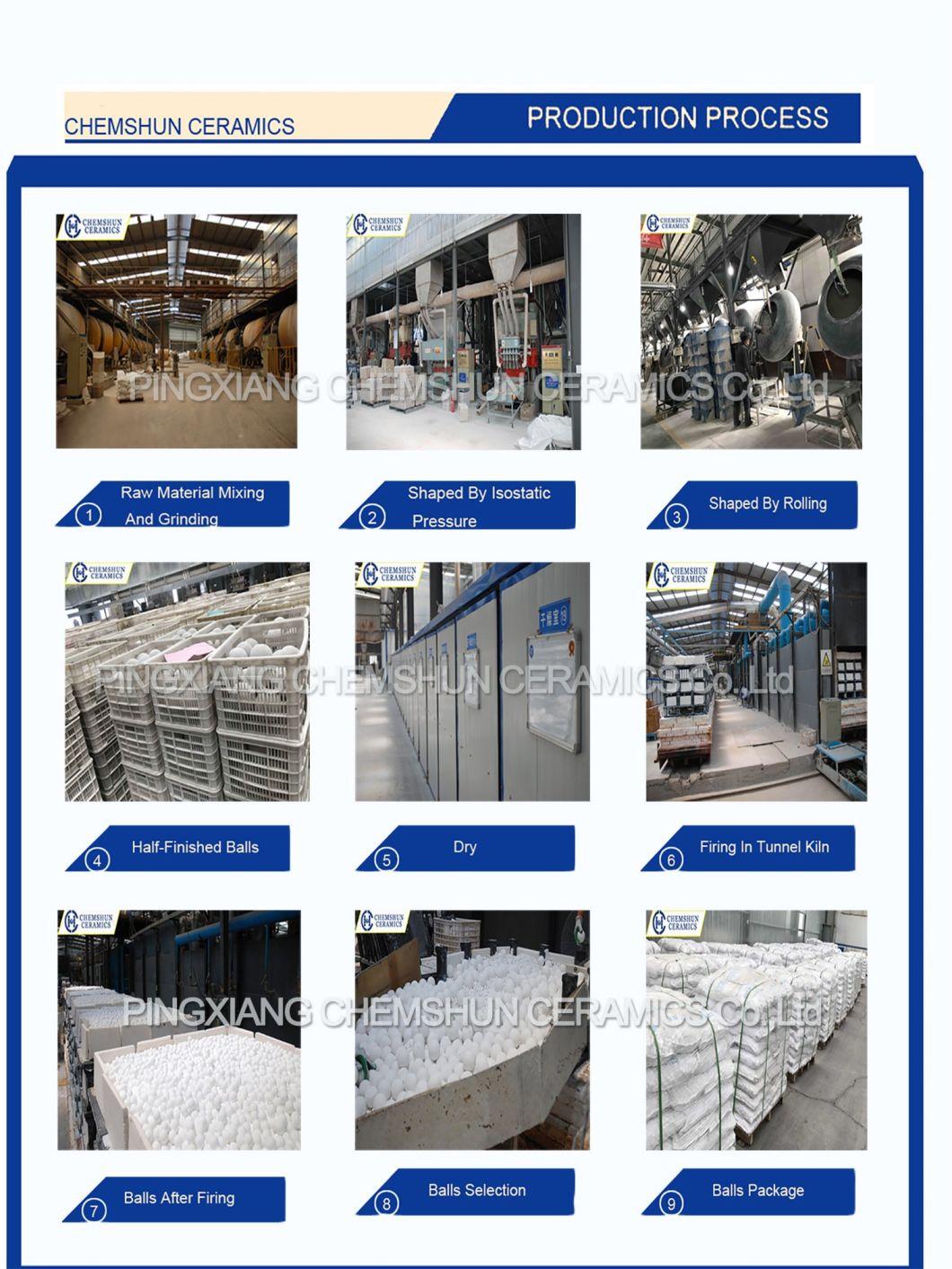

- Processing Type:Isostatic Pressing Type

- Size:Middle, Customized

- Color:White

Base Info

- Model NO.:CS 12-112

- Customized:Customized

- Item:Ceramic Ball

- Materials:Alumina

- Alumina Content:92%, 95%

- Type:High-Alumina

- Feature:High Hardness, High Density

- Application:Ball Mill, Pot Mill, Librating Mill

- Field:Ceramic,Metallurgy, Glass, Porcelain, Enamel

- OEM:Accept

- Transport Package:by Bags, Then Fasten on Pallet

- Specification:D3-70mm

- Trademark:pingxiang chemshun ceramics

- Origin:China

- HS Code:69091200

- Production Capacity:25000ton Per Year

Description

Basic Info.

Model NO. CS 12-112 Customized Customized Item Ceramic Ball Materials Alumina Alumina Content 92%, 95% Type High-Alumina Feature High Hardness, High Density Application Ball Mill, Pot Mill, Librating Mill Field Ceramic,Metallurgy, Glass, Porcelain, Enamel OEM Accept Transport Package by Bags, Then Fasten on Pallet Specification D3-70mm Trademark pingxiang chemshun ceramics Origin China HS Code 69091200 Production Capacity 25000ton Per YearProduct Description

95% Al2O3 Alumina Ceramic Balls for Grinding Mines and Minerals Processing1: Features of 95% grinding ball

--- high density and hardness

--- low wear lost, corrosion-resistance etc.

--- fit for wet or dry grinding

2: Application industry

--- milling glaze/frit,

--- pigment,

--- ceramic materials

--- mine ore powder,

--- cements, paints, refractories, inorganic mineral powders etc...

3: Application--grinding materials

--- mineral grinding,

--- quartz grinding,

--- lineston grinding,

--- iron ore grinding,

--- cement grinding,

--- ceramics plants grinding,

--- pigment grinding,

--- mineral ore grinding,

--- breaking platns.

4: Application--ball mill

--- pot mill,

--- librating mill,

--- pebble mill,

--- Attrition Mill,

--- rod mill etc

5: Size:

1mm, 3mm, 6mm, 9mm, 13mm, 16mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm, 70mm, 95mm

1: 92% 95% 68% Alumina content series

A) Al2O3 ≥ 92%

B) Water absorption <0.01%

C) Bulk density ≥ 3.63 g/cm3

D) Mosh hardness: 9

E) Color: White

2: 95% High-alumina grinding ball

A) Al2O3 ≥ 95% Sio2<3.8%, others: ~3%

B) Water absorption <0.01%

C) Bulk density ≥ 3.7 g/cm3

D) Mosh hardness: 9

E) Color: White

F) self abrasion loss: <0.008%

3: 68% Medium alumina grinding ball series:

A) Al2O3: 65%~75%

B) Bulk density ≥ 2.93g/cm3

C) Mosh hardness: 8 grade

D) self abrasion loss: 0.01

E) Color: White or brown

| Items | Proportion | Items | Proportion |

| Al2O3 | 92% | SiO2 | <6.5% |

| others | ~2% |

| Items | Proportion | Items | Proportion |

| Hardness: Mohr's | 9 | self Abrasion Loss (24hour) | <0.01% |

| Density(g/cm3) | 3.6 g/cm3 | Water Absorption | <0.01% |

| Color | White | Ball method | By cool isostatic-pressing Or by rolling |

95% Alumina ball chemical and physical introduction :

| Items | Proportion | Items | Proportion |

| Al2O3 | 95% | SiO2 | <3% |

| others | ~2% |

Physical Analysis:

| Items | Proportion | Items | Proportion |

| Hardness: Mohr's | 9 | self Abrasion Loss (24hour) | <0.01% |

| Density(g/cm3) | 3.74g/cm3 | Water Absorption | <0.01% |

| Color | White | Ball method | By cool isostatic-pressing Or by rolling |

68% Alumina ball chemical and physical introduction :

| Items | Proportion | Items | Proportion |

| Al2O3 | 68.62% | SiO2 | 21.2% |

| others | ~10.18% |

Physical Analysis:

| Items | Proportion | Items | Proportion |

| Hardness: Mohr's | 7-8 | self Abrasion Loss (24hour) | <0.03% |

| Density(g/cm3) | 3.0 g/cm3 | Water Absorption | <0.1% |

| Color | creamy white | Ball method | By cool isostatic-pressing Or by rolling |